Oxygen-free high-purity arsenic powder preparing method

A high-purity arsenic and zirconia technology, applied in grain processing and other directions, can solve the problems that arsenic powder cannot meet high-purity requirements, destroy products, etc., and achieve the effects of low oxygen content, high recovery rate and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

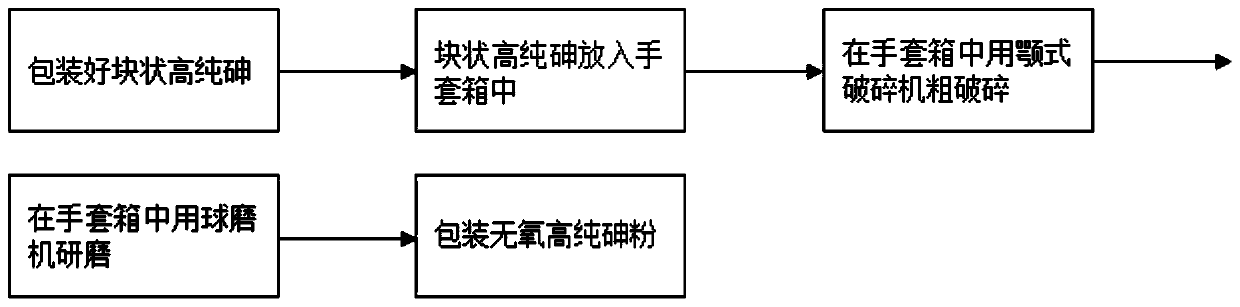

[0021] This example is an example of the preparation method of the oxygen-free high-purity arsenic powder of the present invention. The preparation method of the present embodiment oxygen-free high-purity arsenic powder according to figure 1 The process is carried out, specifically: transfer a bottle of 1.50 kg arsenic block (purity: 7N) with a particle size of 3-15 mm into a glove box filled with inert gas through a transition chamber, and the jaw crusher in the glove box The gap between the jaw plates is adjusted to 1 mm, and the frequency is 5 Hz, then the above-mentioned arsenic block is added to the jaw crusher at a constant speed for crushing, and 1.49 kg of small arsenic particles are collected, and then these small arsenic particles are transferred into the glove box. In a ball mill barrel (using 3 kg of zirconia balls with a diameter of 15 mm as the grinding body), ball mill at a speed of 40 r / min for 1 hour to obtain 1.48 kg of arsenic powder, which is packed with an...

Embodiment 2

[0023] This example is an example of the preparation method of the oxygen-free high-purity arsenic powder of the present invention. The preparation method of the present embodiment oxygen-free high-purity arsenic powder according to figure 1 The process is carried out, specifically: transfer a bottle of 3.00kg arsenic block (purity: 7N) with a particle size of 3-15mm into a glove box filled with inert gas through a transition chamber, and the jaw crusher in the glove box The gap between the jaw plates was adjusted to 5 mm, and the frequency was 5 Hz. Then, the above-mentioned arsenic block was fed into the jaw crusher at a constant speed for crushing, and 2.99 kg of small arsenic particles were collected, and then these small arsenic particles were transferred into the glove box. In a ball mill barrel (with 1.5 kg of zirconia balls with a diameter of 5 mm as the grinding body), ball mill at a speed of 80 r / min for 2 hours to obtain 2.98 kg of arsenic powder, which is packed wi...

Embodiment 3

[0025] This example is an example of the preparation method of the oxygen-free high-purity arsenic powder of the present invention. The preparation method of the present embodiment oxygen-free high-purity arsenic powder according to figure 1 The process is carried out, specifically: transfer a bottle of 3.00kg arsenic block (purity: 7N) with a particle size of 3-15mm into a glove box filled with inert gas through a transition chamber, and the jaw crusher in the glove box The gap between the jaw plates was adjusted to 5 mm, and the frequency was 5 Hz. Then, the above-mentioned arsenic block was fed into the jaw crusher at a constant speed for crushing, and 2.99 kg of small arsenic particles were collected, and then these small arsenic particles were transferred into the glove box. In a ball mill bucket (using 3 kg of zirconia balls with a diameter of 5 mm as the grinding body), ball mill at a speed of 80 r / min for 0.5 h to obtain 2.98 kg of arsenic powder, which is packed with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com