Positioning device and welding method for butt welding of thin-walled tubes

A technology of positioning device and welding method, applied in welding equipment, welding accessories, laser welding equipment, etc., can solve the problems of high scrap rate and difficult positioning of thin-walled pipe welding, so as to reduce scrap rate and cost, and improve the overall welding Efficiency, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

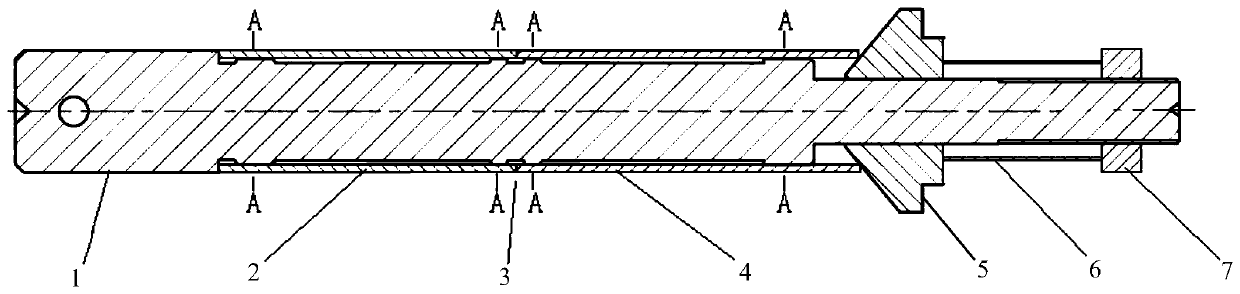

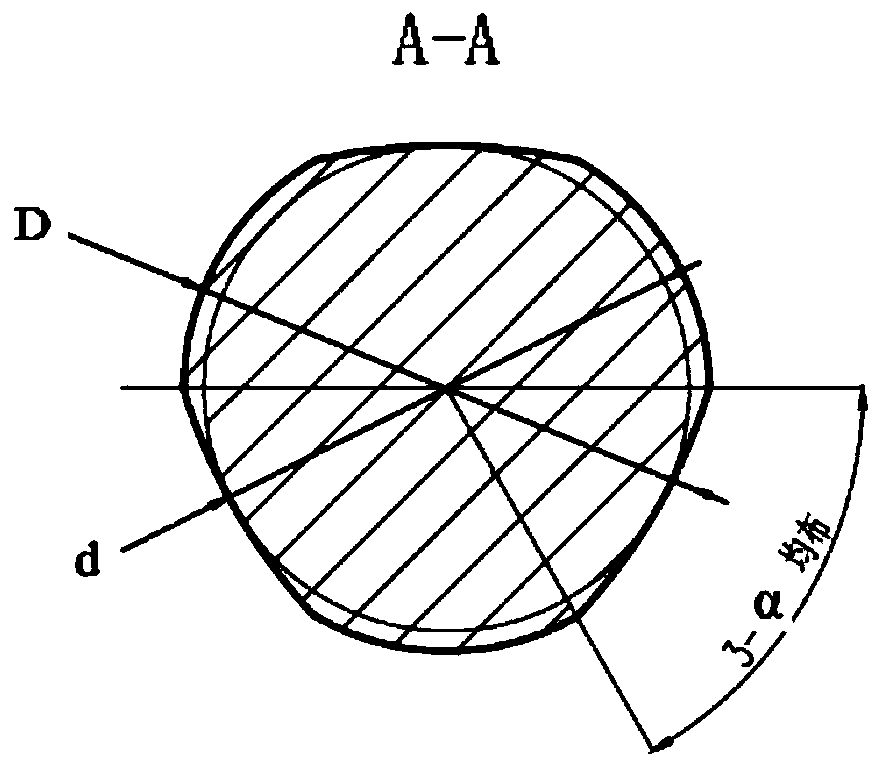

[0037] A tungsten thin-walled tube has an outer diameter of 14mm, a wall thickness of 0.5mm, and a length of 100mm. Two pieces are butt-welded by electron beam self-fusion. The specific method is as follows:

[0038] Positioning device: The positioning device includes a mandrel, a plug, a spring and a fastening nut. One end of the mandrel is the clamping part of the chuck, which is designed as a cylinder with a diameter of 14mm. Four cam structures are designed and processed on the mandrel. The width of the cam structure along the mandrel axis is 5mm. Each cam structure includes three protrusions evenly distributed in the circumferential direction, where α is 90°, the major diameter D is 13 mm, and the minor diameter d is 11 mm. The distance between two adjacent cam structures at the butt weld of the thin-walled pipe is 3mm.

[0039] Installation and welding method: Set two thin-walled tubes on the mandrel in turn to ensure that the end faces are in close contact; install the...

Embodiment 2

[0041] A TZM alloy thin-walled tube has an outer diameter of 20mm, a wall thickness of 1mm, and a length of 80mm. The same three tubes are installed at one time for laser self-fluxing butt welding. The specific method is as follows:

[0042] Positioning device: The positioning device includes a mandrel, a plug, a spring and a fastening nut. One end of the mandrel is the clamping part of the chuck, designed as a cylinder with a diameter of 20mm, and 6 cam structures are designed and processed on the mandrel, and the width of the cam structure along the mandrel axis is 8mm. The cam structure includes three protrusions evenly distributed in the circumferential direction, where α is 100°, the major diameter D is 18 mm, and the minor diameter d is 16 mm. The distance between two cam structures at the butt weld of adjacent thin-walled pipes is 5 mm.

[0043] Installation and welding method: Set three thin-walled tubes on the mandrel in turn to ensure close contact between the end fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com