Preparation process of crackle-free powder bluish-green glaze craft porcelain

A preparation process and technology of powder green glaze, which is applied in the field of preparation of non-split powder green glaze process porcelain, can solve the problems of product glaze color deviation, low yield rate, difficult control, etc., achieve soft glaze luster, ensure strength, and improve intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

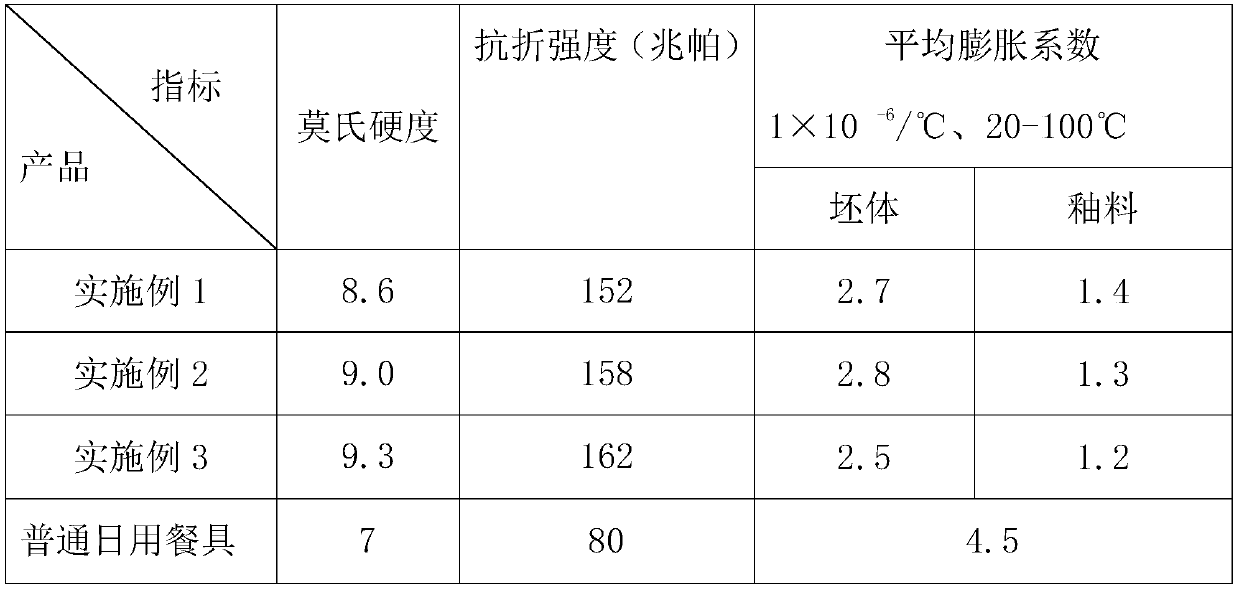

Examples

Embodiment 1

[0053] A blue-glazed craft porcelain without flake powder, including a body and a glaze.

[0054]The green body includes the following raw materials in parts by weight: 23 parts of feldspar, 30 parts of Dehua kaolin, 35 parts of Dehua quartz, 15 parts of dolomite, 10 parts of sepiolite, 8 parts of diatomite, 16 parts of spodumene, silicon 1 part of zirconium acid, 1 part of titanium oxide, and 0.3 part of tin oxide.

[0055] The glaze includes the following raw materials in parts by weight: 15 parts of anorthite, 20 parts of brucite, 10 parts of diopside, 30 parts of Dehua quartz, 8 parts of frit, 3 parts of manganese oxide, 3 parts of iron oxide, titanium oxide 1 part, 2 parts of nickel oxide.

[0056] The chemical composition of the frit is as follows: SiO 2 : 58.3%, Al 2 o 3 : 16.2%, MgO: 9.2%, K 2 O: 4.1%, Fe 2 o 3 : 5.8%, ZnO: 4.1%, Li 2 O: 2.3%.

[0057] Its preparation process comprises the following steps:

[0058] Step 1, weighing and proportioning according...

Embodiment 2

[0075] A blue-glazed craft porcelain without flake powder, including a body and a glaze.

[0076] The green body includes the following raw materials in parts by weight: 30 parts of feldspar, 25 parts of Dehua kaolin, 30 parts of Dehua quartz, 18 parts of dolomite, 5 parts of sepiolite, 12 parts of diatomite, 10 parts of spodumene, silicon 3 parts of zirconium acid, 0.5 parts of titanium oxide, and 0.5 parts of tin oxide.

[0077] The glaze includes the following raw materials in parts by weight: 18 parts of anorthite, 15 parts of brucite, 12 parts of diopside, 20 parts of Dehua quartz, 10 parts of frit, 1 part of manganese oxide, 5 parts of iron oxide, titanium oxide 2 parts, 1 part of nickel oxide.

[0078] The chemical composition of the frit is as follows: SiO 2 : 65.8%, Al 2 o 3 : 12.7%, MgO: 7.8%, K 2 O: 4.7%, Fe 2 o 3 : 5.2%, ZnO: 2.2%, Li 2 O: 1.6%.

[0079] Its preparation process comprises the following steps:

[0080] Step 1, weighing and proportioning acc...

Embodiment 3

[0097] A blue-glazed craft porcelain without flake powder, including a body and a glaze.

[0098] The green body includes the following raw materials in parts by weight: 27 parts of feldspar, 28 parts of Dehua kaolin, 32 parts of Dehua quartz, 16 parts of dolomite, 8 parts of sepiolite, 10 parts of diatomite, 13 parts of spodumene, silicon 2 parts of zirconium acid, 0.8 parts of titanium oxide, and 0.4 parts of tin oxide.

[0099] The glaze includes the following raw materials in parts by weight: 16 parts of anorthite, 18 parts of brucite, 11 parts of diopside, 25 parts of Dehua quartz, 9 parts of frit, 2 parts of manganese oxide, 4 parts of iron oxide, titanium oxide 1.5 parts, nickel oxide 1.5 parts.

[0100] The chemical composition of the frit is as follows: SiO 2 : 62.7%, Al 2 o 3 : 14.1%, MgO: 8.3%, K 2 O: 4.4%, Fe 2 o 3 : 5.5%, ZnO: 3.3%, Li 2 O: 1.7%.

[0101] Its preparation process comprises the following steps:

[0102] Step 1, weighing and proportioning a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com