The synthetic method of tetrakis(dimethylamino)titanium

A dimethylamino and synthetic method technology, applied in the field of compound synthesis, can solve problems such as waste of raw materials, yield of dimethylamine, easy escape of dimethylamine, and reduction of dimethylamine, so as to achieve the effect of improving the conversion rate and environmental protection of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

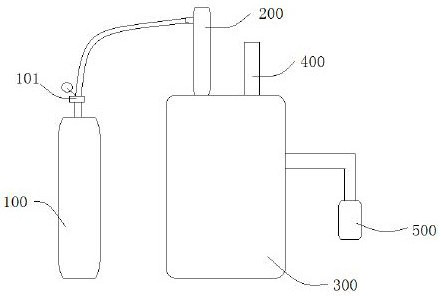

Image

Examples

preparation example Construction

[0030] The embodiment of the invention provides a synthesis method of tetra (dimethylamino) titanium, which comprises the following steps:

[0031] Mixing an alkane solvent and an organometallic lithium compound to prepare a first reactant;

[0032] Leading out dimethylamine gas at a gas outflow pressure of 0.12~0.15MPa, condensing the dimethylamine gas at a temperature of-10--20 DEG C, and adding the formed dimethylamine condensate into the first reactant for a first reaction to prepare a second reactant;

[0033] Adding titanium tetrachloride into the second reactant for a second reaction, and preparing the tetra (dimethylamino) titanium through post-treatment.

[0034] The synthesis of tetra (dimethylamino) titanium mainly includes two steps: (1) Dimethylamine reacts with organometallic lithium compounds to produce intermediate lithium dimethylamino; (2) lithium dimethylamino reacts with titanium tetrachloride to obtain tetra (dimethylamino) titanium.

[0035] In step (1), specif...

Embodiment 1

[0070] In this embodiment, a method for synthesizing tetra (dimethylamino) titanium comprises the following specific steps:

[0071] 1, the reaction device is a 2L reaction bottle, which is replaced by a vacuum / nitrogen system for three times, and 500mL of n-hexane and 500mL of n-butyl lithium (2.5m) are added in the nitrogen atmosphere; Obtaining a first reactant;

[0072] Secondly, the high-pressure gas storage device is a dimethylamine gas steel cylinder, and the gas outflow pressure of dimethylamine gas is controlled to be 0.12MPa; by adjusting a pressure reducing valve arranged on the high-pressure gas storage device; The dimethylamine gas flowing out of the pressure reducing valve passes through a serpentine condenser with a condensation temperature of -15℃, condenses to form dimethylamine condensate, and slowly drops into the reaction device to mix with the first reactant, controlling the temperature in the reaction device to -20℃, and introducing 56g; of dimethylamine in t...

Embodiment 2

[0076] In this embodiment, a method for synthesizing tetra (dimethylamino) titanium comprises the following specific steps:

[0077] 1, the reaction device is a 2L reaction bottle, which is replaced by a vacuum / nitrogen system for three times, and 600mL of n-heptane and 550mL of n-butyl lithium (2.5m) are added in the nitrogen atmosphere; Obtaining a first reactant;

[0078] Secondly, the high-pressure gas storage device is a dimethylamine gas steel cylinder, and the gas outflow pressure of dimethylamine gas is controlled to be 0.13MPa; by adjusting a pressure reducing valve arranged on the high-pressure gas storage device; The dimethylamine gas flowing out of the pressure reducing valve passes through a serpentine condenser with a condensation temperature of -15℃, condenses to form dimethylamine condensate, and slowly drops into the reaction device to mix with the first reactant, controlling the temperature in the reaction device to -20℃, and introducing 62g; dimethylamine in tot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com