Supporting structure and supporting system thereof used for side slope support protection

A support structure and support system technology, applied in the direction of basic structure engineering, excavation, coating, etc., can solve the problems of large deformation of the slope, affecting driving safety, and insufficient driving comfort, so as to improve driving comfort and strengthen support ability, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In conjunction with the accompanying drawings, the present invention will be further described in detail.

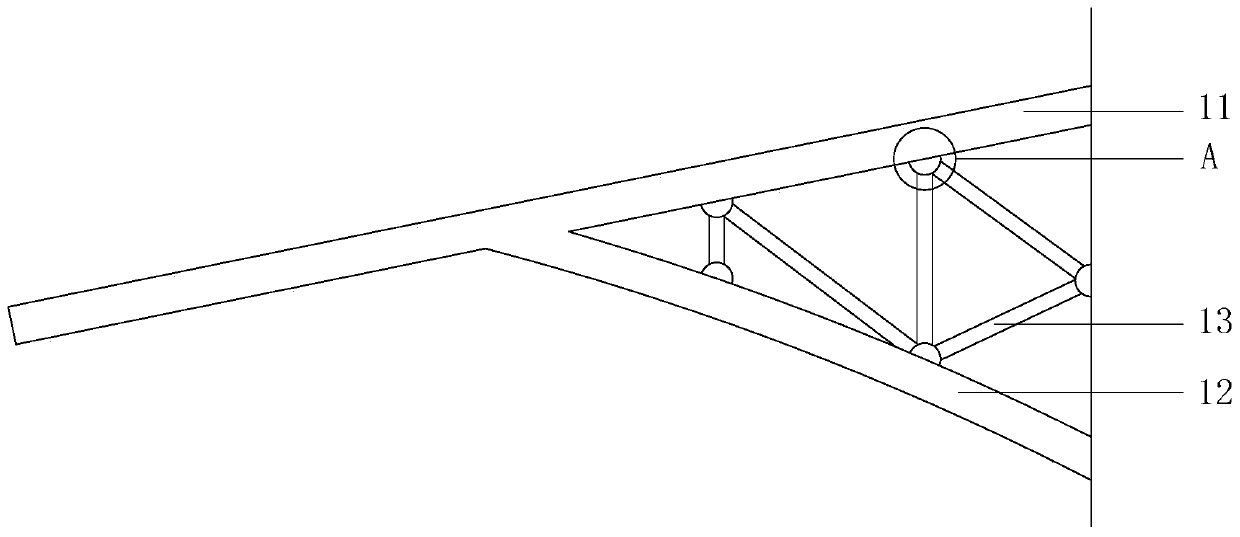

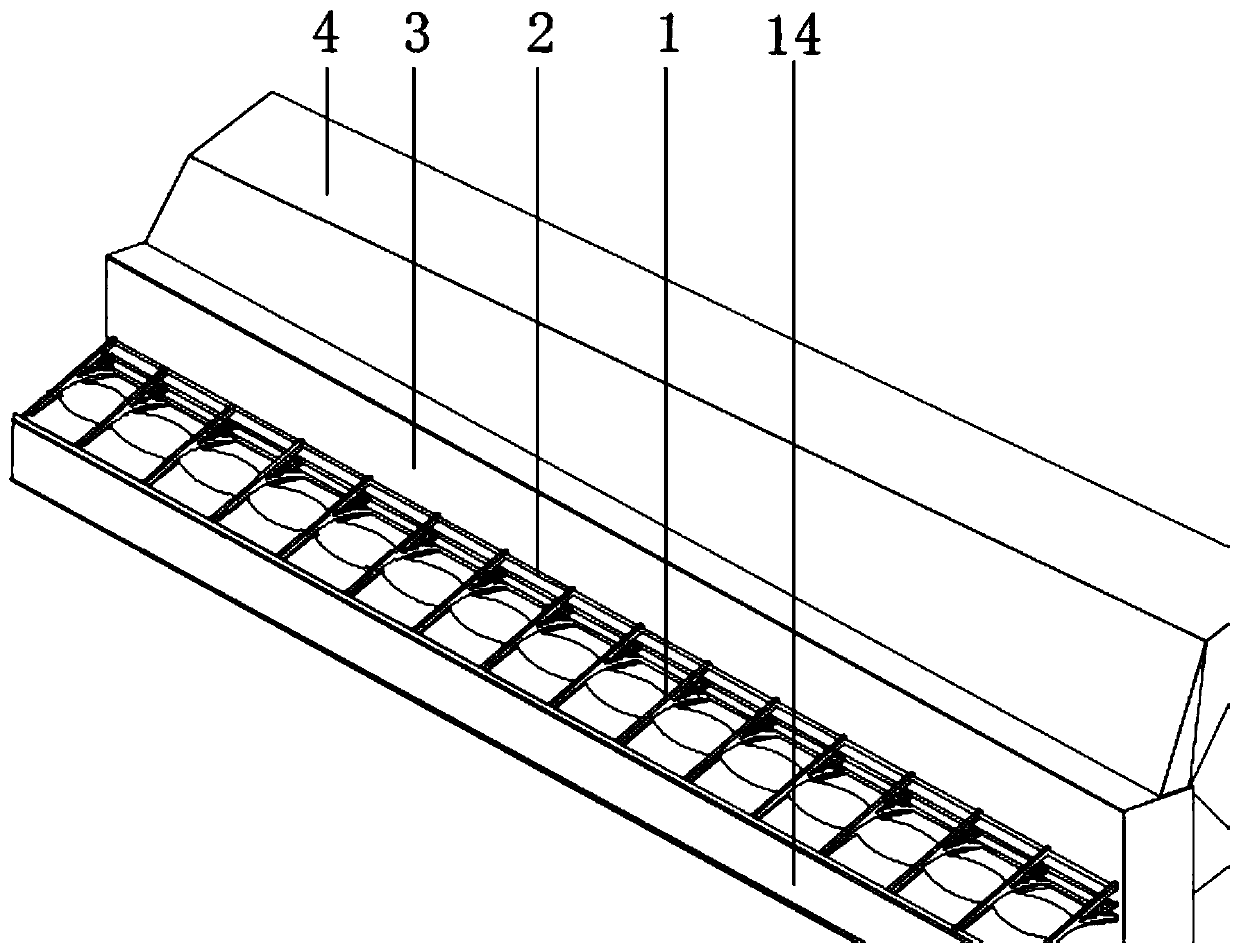

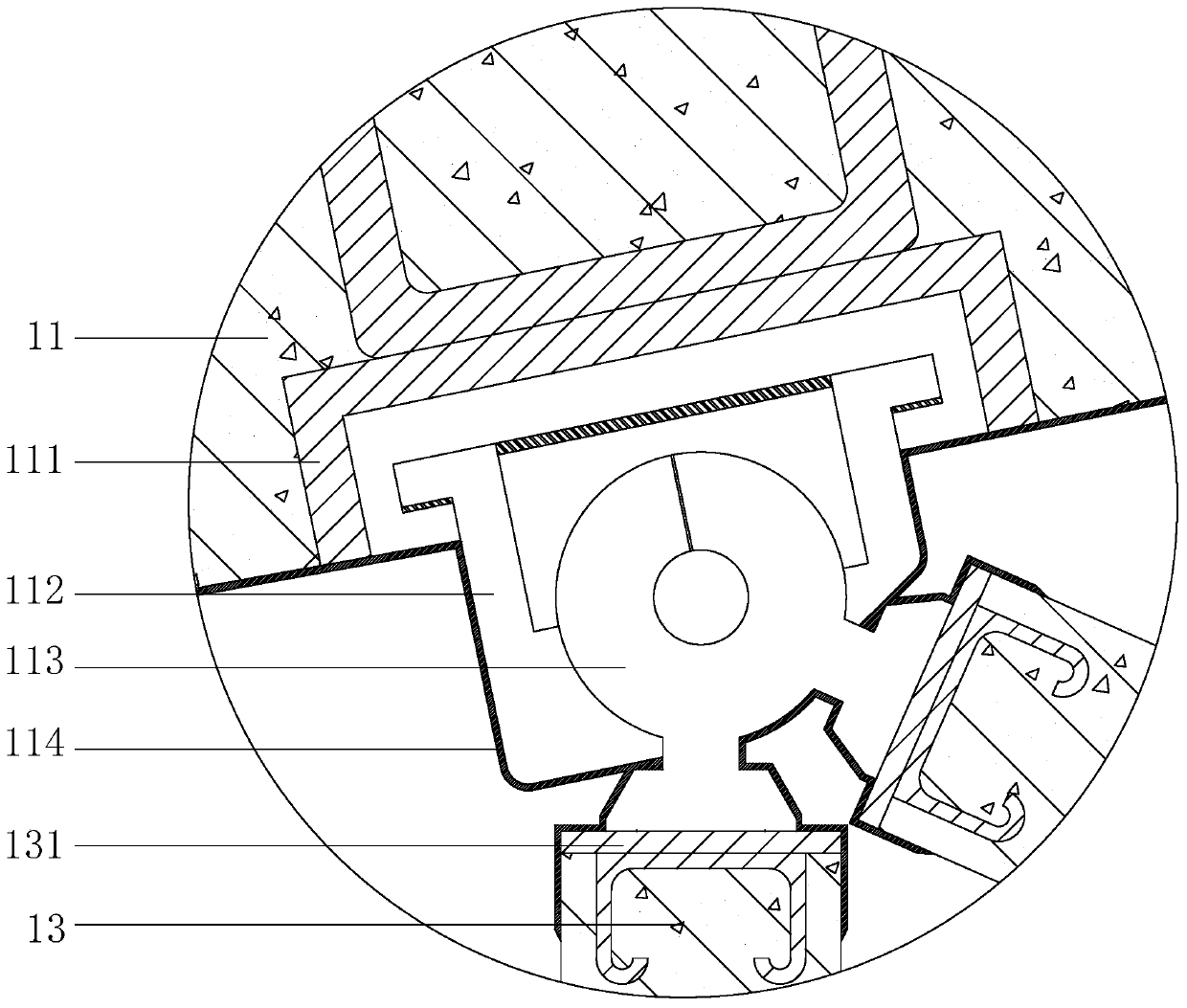

[0021] As shown in the figure, a support structure and its support system for slope protection include a support structure 1, a longitudinal tie beam 2, a support structure 3, and a slope 4; the support structure 1 is composed of a support inclined column 11. The arch rib 12, the web bar 13 and the support foundation 14 are composed, wherein the support slant column 11 is a reinforced concrete column structure, and one end of the support slant column 11 is fixedly connected to the support foundation 14, and the other end is fixedly connected to the support on the side of the slope 4. On the longitudinal tie beam 2 of the protective structure 3; the minimum distance between the support foundation 14 and the slope surface of the side slope 4 is 8-20m, and the support foundation 14 top is built with a longitudinal tie beam 2, and the longitudinal tie beam 2 side and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com