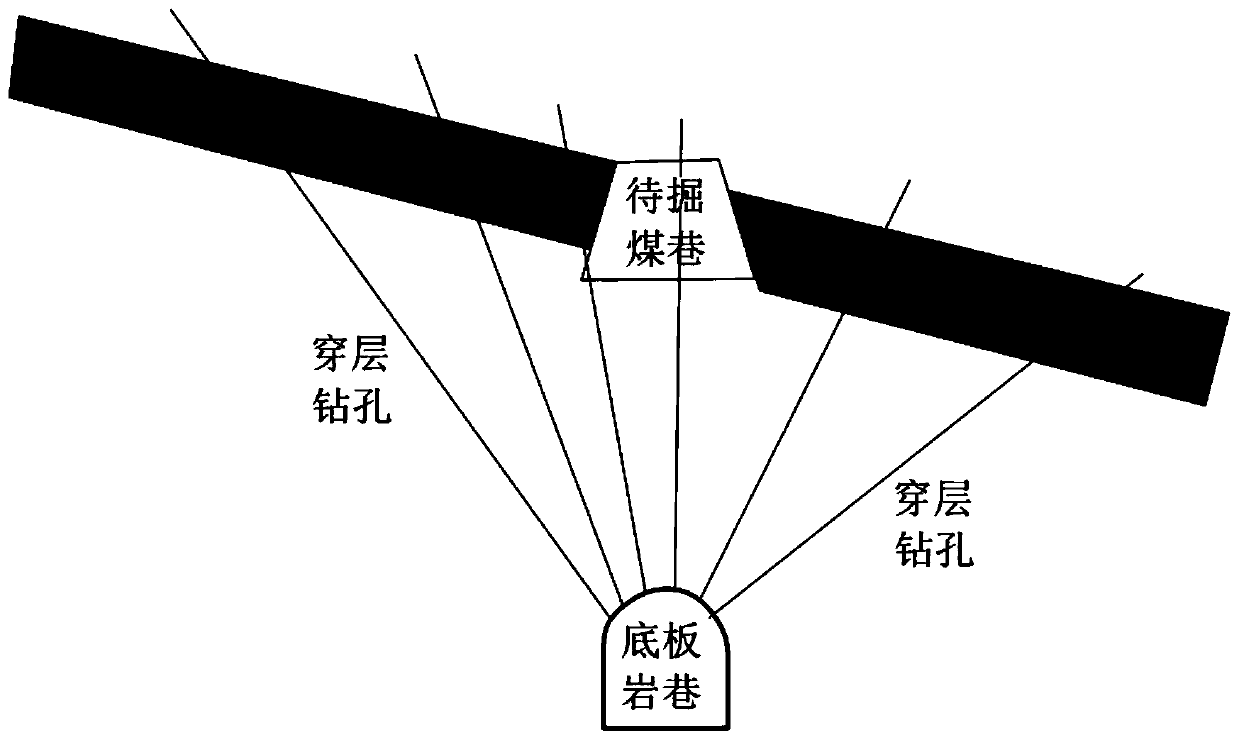

Technical method for rapid gas extraction standard reaching in broken soft, low-permeability and outburst coal seam by replacing roadways with holes

A technology for outburst coal seam and gas extraction, which is applied to the field of rapid gas extraction in broken soft and low-permeability outburst coal seams with holes instead of roadways, which can solve the problem that it is difficult to meet the requirements of excavation and extraction, and there are blind spots, blind sections and branches in the extraction area. Due to the limited number of drainage holes, the effect of shortening the drainage compliance period, reducing the production cost and construction difficulty, and improving the gas desorption and migration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

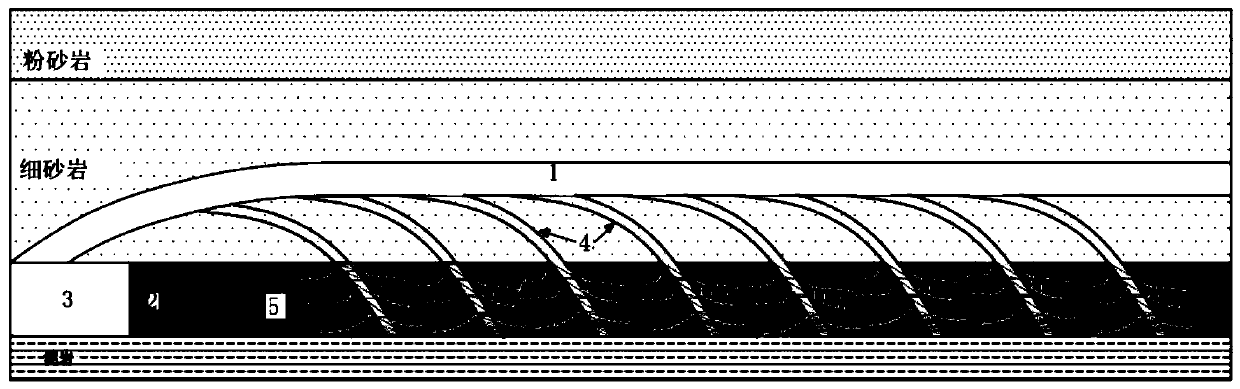

[0047] Such as figure 2 As shown, for the control area where the floor roadway has not been excavated, and the roof of the coal seam 2 has rock formations with stable layers and high mechanical strength, the construction drilling site 3 is arranged in the mining face, and the super-long directional drilling 1 and 1 of the roof are implemented. The combination of small radius of curvature branch holes 4 is used for advanced pre-extraction. At this time, the combination of ultra-long directional drilling 6 on the bottom plate and small curvature radius branch holes 4 can also be used for advanced pre-extraction.

[0048] In this embodiment, since the small radius of curvature branch borehole 4 on the roof of the coal seam 2 extends to the inside of the coal seam 2, after hydraulic fracturing is used to increase permeability, it is difficult for high-pressure water to flow back, and it is easy to cause the problem of water blockage of the gas migration channel. , the branch hole...

Embodiment 2

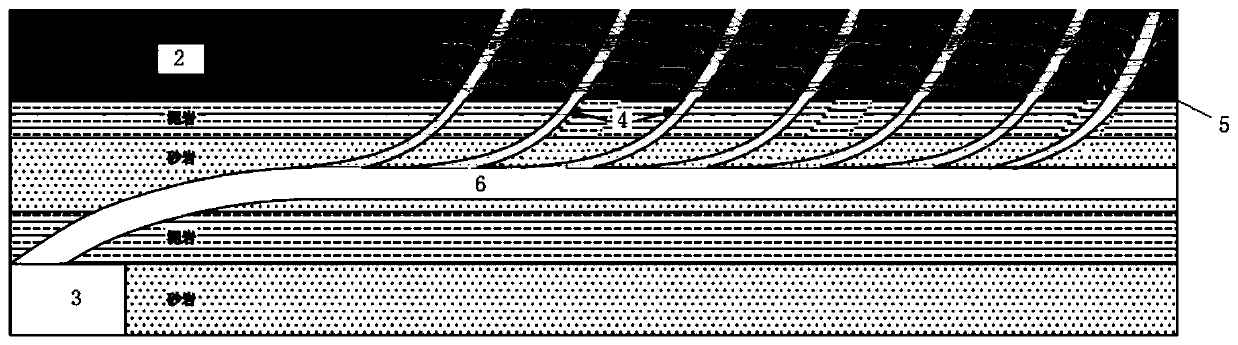

[0050] Such as image 3 As shown, for the control area that has started to excavate the bottom pumping roadway, but has not yet formed a certain scale, or the roof does not have the conditions for direct construction, set up a drilling site 3 in the stable rock formation of the coal seam 2 and the floor, and drill through the super-long directional drilling of the floor 6 Advanced pre-extraction is carried out in combination with small curvature radius branch drilling 4.

[0051] The ultra-long directional drilling 6 of the bottom plate and the small curvature radius branch drilling 4 are all upward drilling. After hydraulic fracturing, the high-pressure water flows back, so the small curvature radius branch drilling 4 of the bottom plate first adopts hydraulic Fracturing, and then using gas anti-permeability technology.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com