Device and method for prefabricating cracks in coal rock sample at any angle

An arbitrary angle, coal-rock technology, applied in the field of coal-rock mechanics experiment research, can solve the problems of simulating the internal crack shape, not being able to prefabricate cracks, weakening and processing ideal cracks, etc., and achieve the effect of saving space and preventing twisting and water blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

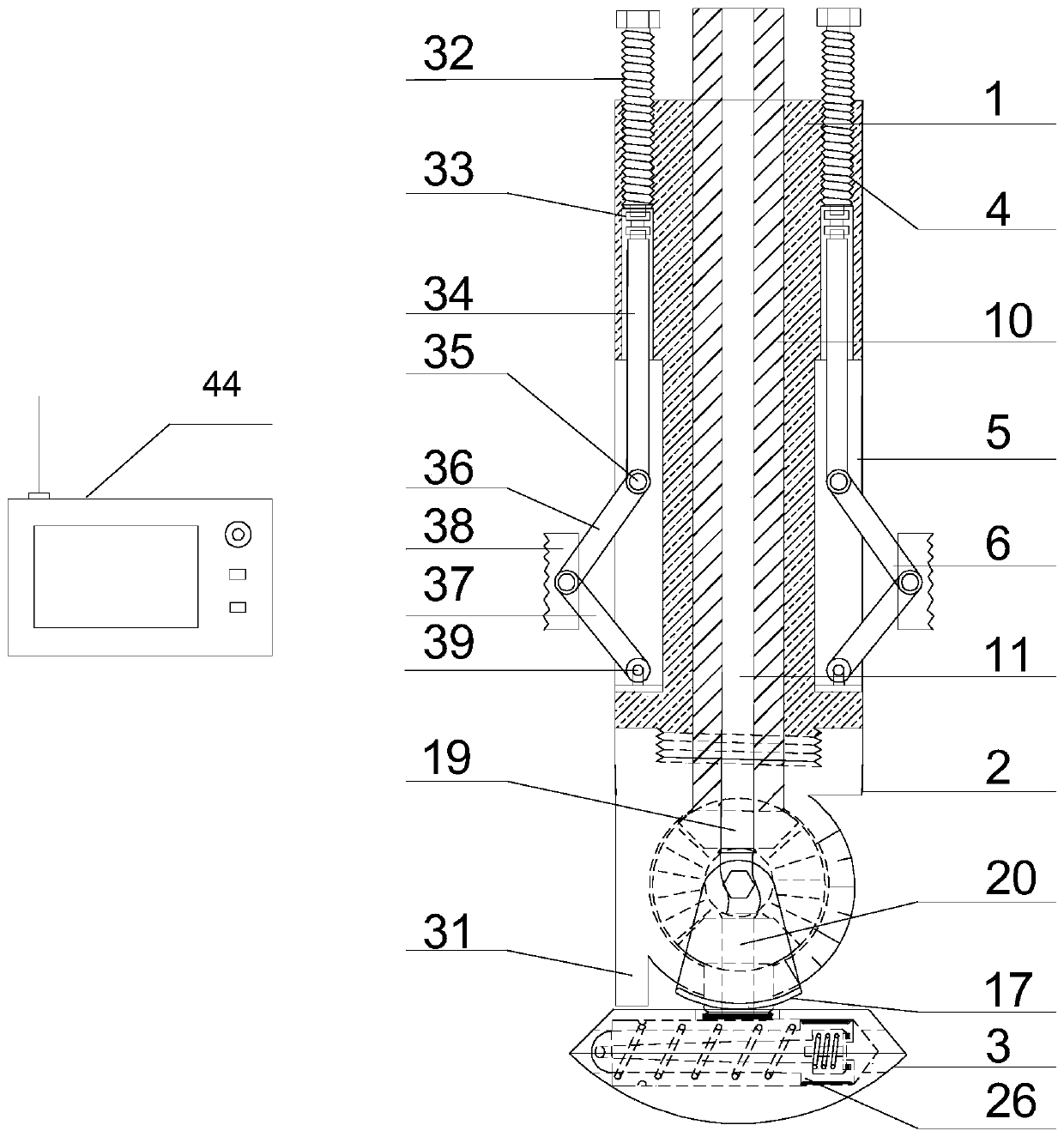

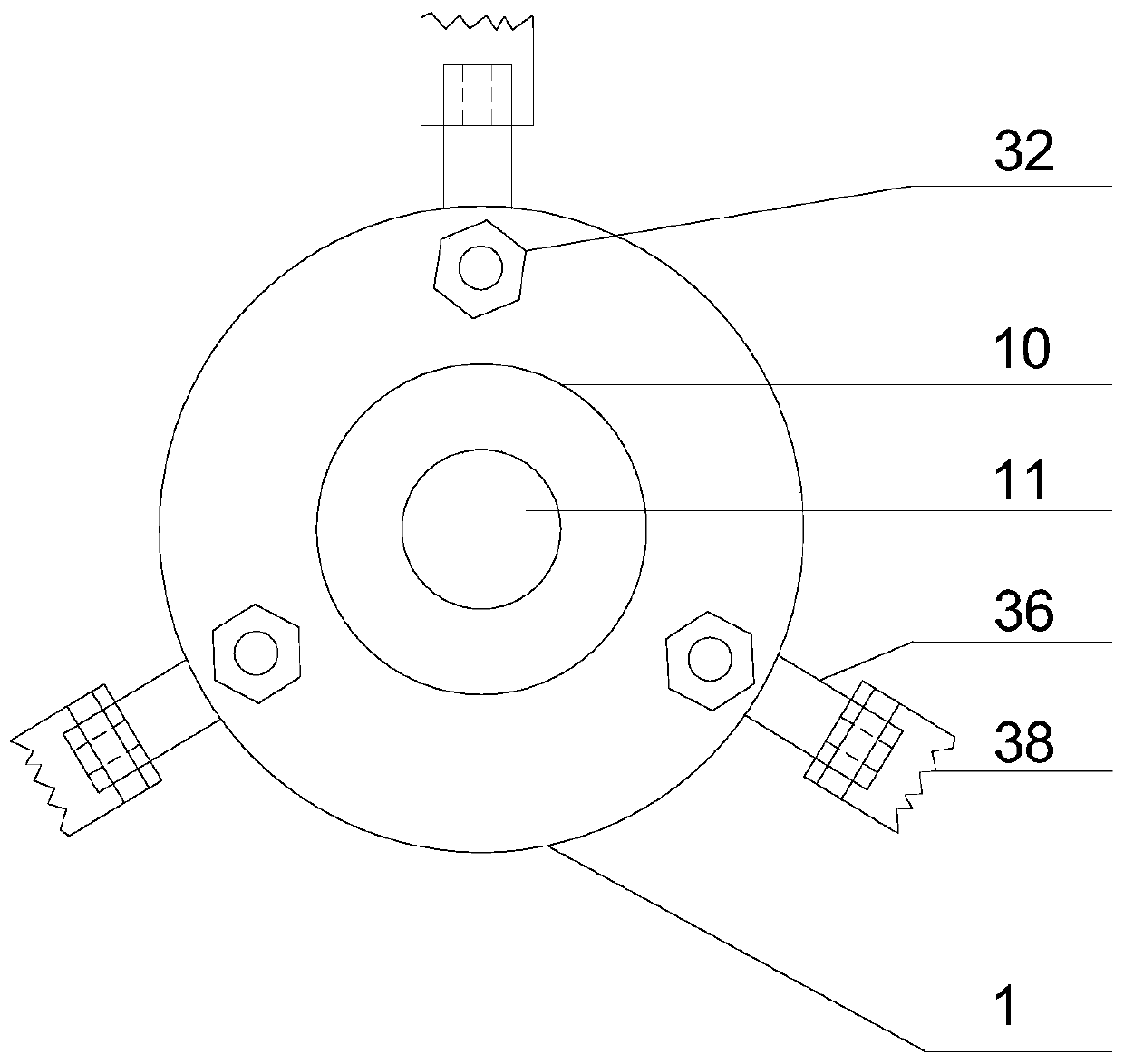

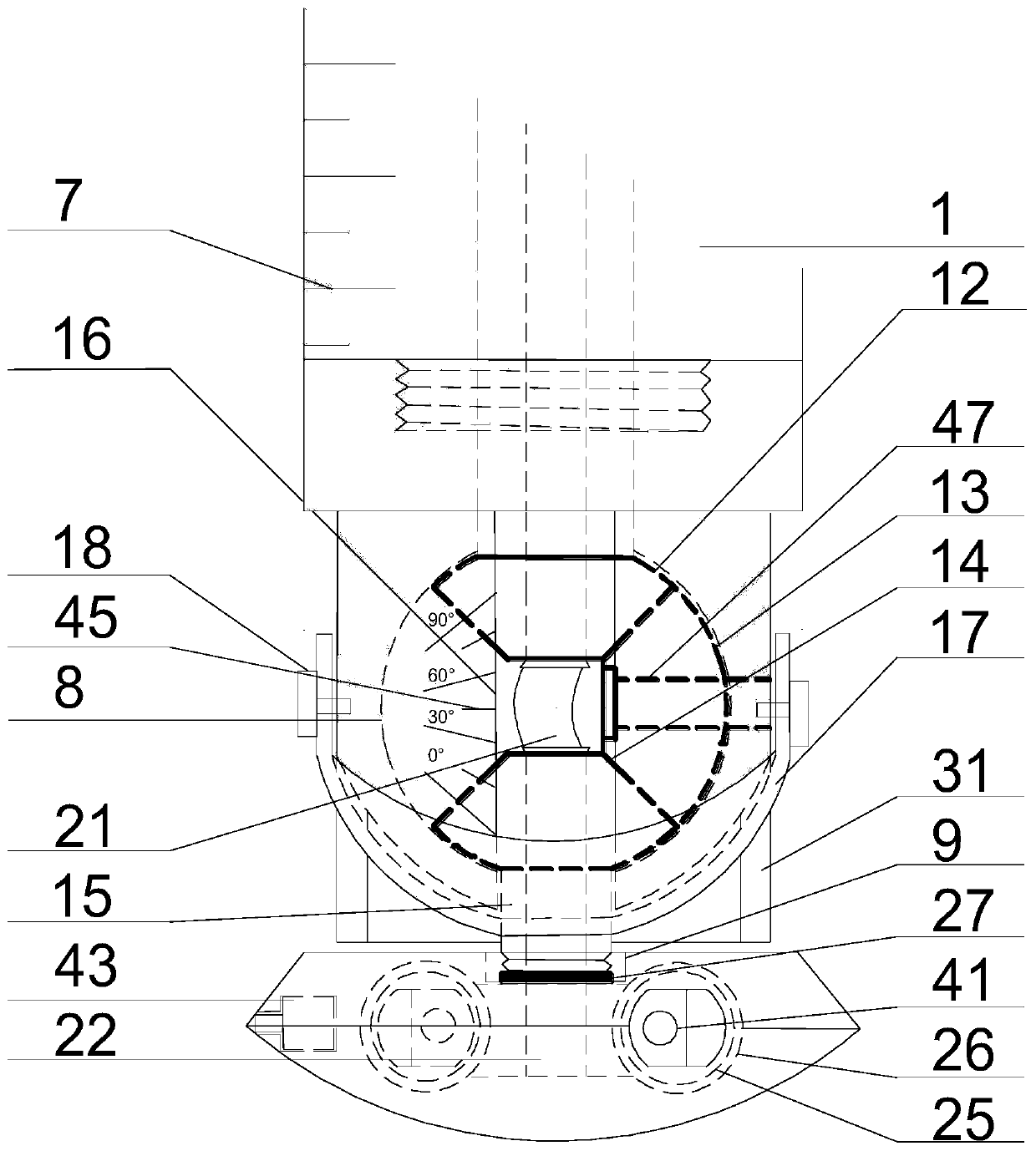

[0040] Such as Figure 1 to Figure 4 As shown, the present invention provides a crack prefabrication device at any angle inside a coal sample, including a position control module 1, an angle adjustment module 2, a mechanical-hydraulic joint cutting module 3 and a laser ranging module,

[0041] The position control module 1 is connected to the upper end of the angle adjustment module 2 by threads, and three threaded holes 4 are evenly spaced in the circumferential direction of the position control module 1, and the lower part of each threaded hole 4 communicates with a sliding groove 5 respectively. A stabilizer 6 is installed in the sliding groove 5, and a pre-tightening bolt 32 is rotated in the threaded hole 4, and the lower end of the pre-tightening bolt 32 is fixed to the upper end of the stabilizer 6, and the outer wall of the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com