Lithium battery film coating equipment

A lithium battery and film coating technology, which is applied in the field of lithium battery film coating equipment, can solve the problems of affecting the yield, affecting the production progress, uneven electrode coating, etc., and achieves high production efficiency and uniform coating without occupying production time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

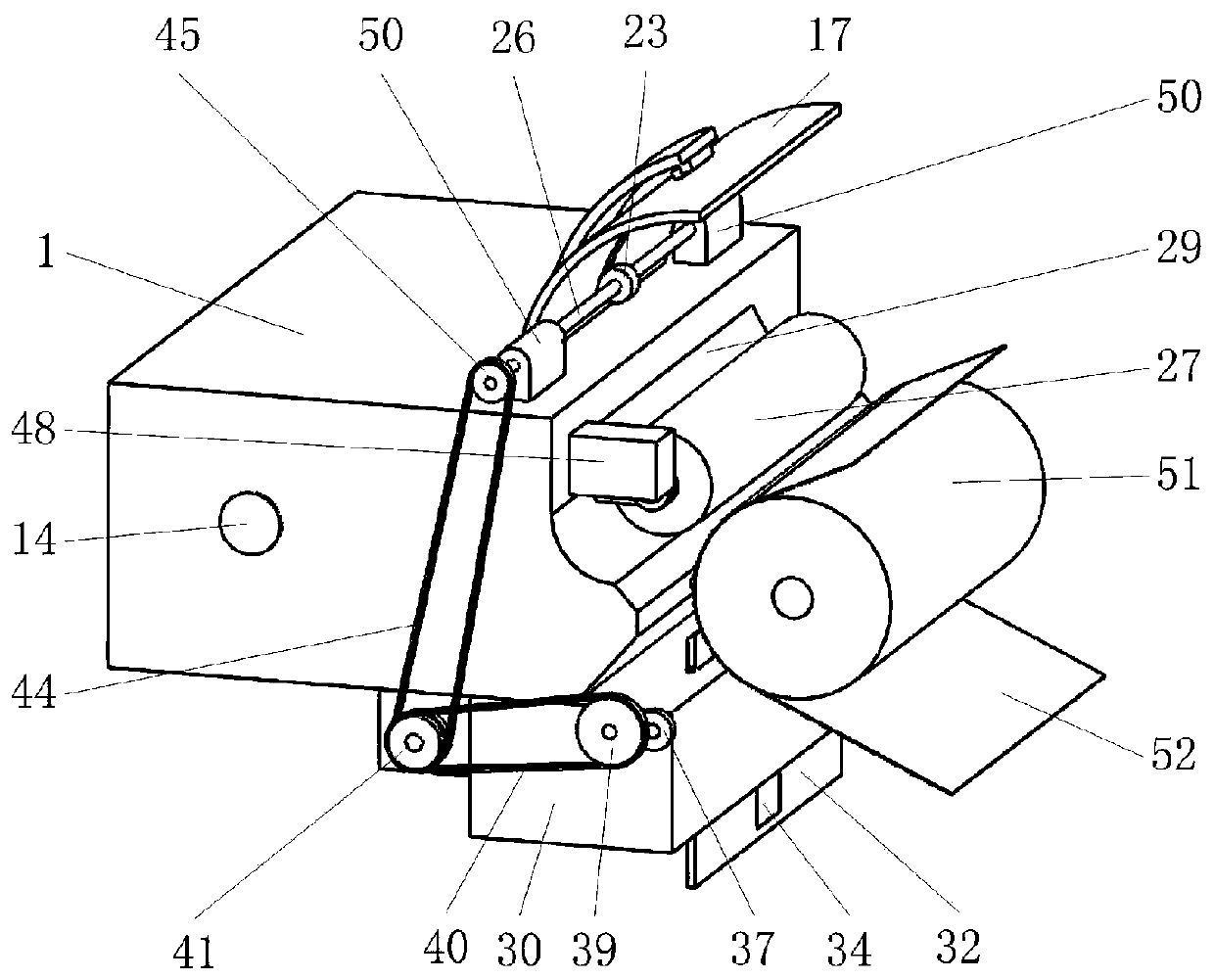

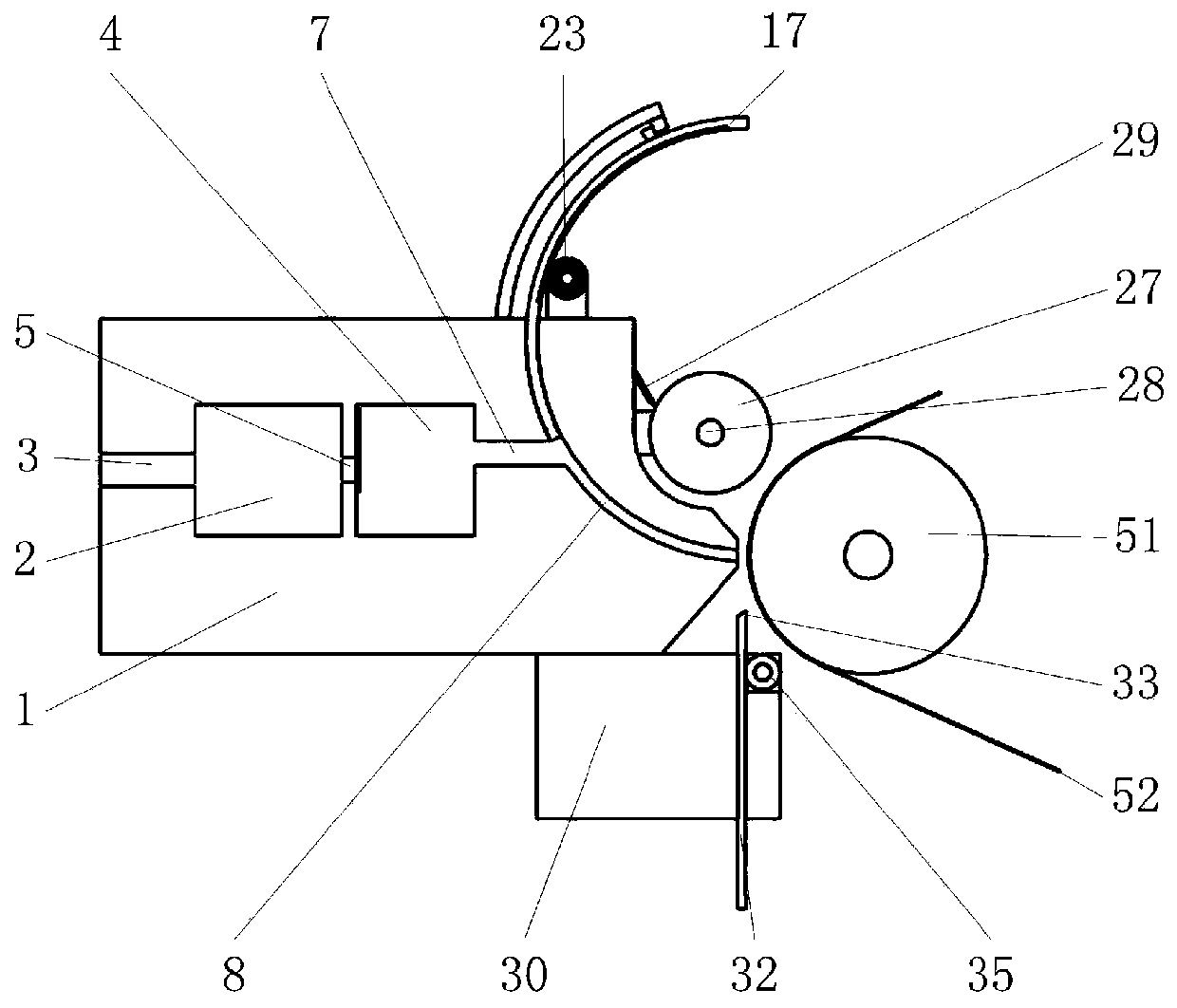

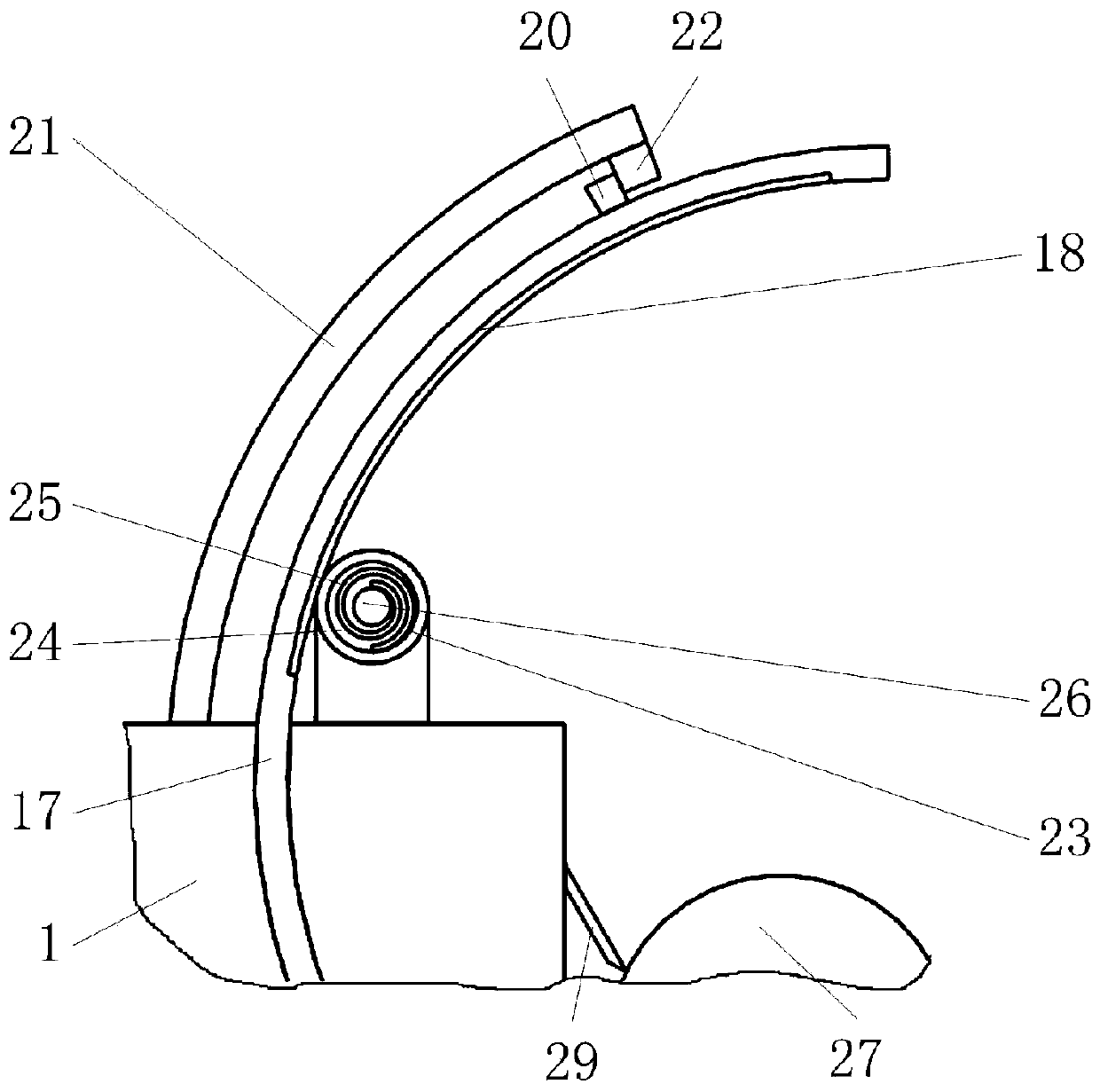

[0038] Such as figure 1 , 2 , 3, it includes extrusion head 1, slider 10, baffle 15, guide pin 16, arc plate A17, gear A23, scroll spring 25, shaft A26, roller A27, scraper 29, guide seat 30, Cleaning plate 32, gear B35, shaft C36, electric drive module A43, electric drive module B48, wherein as Figure 8 , 9 As shown in , 10, the extrusion head 1 has an adjustment groove A2 and an adjustment groove C4 communicated through a narrow adjustment groove B5, and the adjustment groove C4 communicates with the middle of the arc-shaped extrusion groove 8 in the extrusion head 1 through the communication groove 7 , and the communication groove 7 and the extrusion groove 8 are equal in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com