Spacer for insulating glazings, comprising an electric feed line integrated into a hollow chamber

A technology that integrates power feeds and glass windows, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve problems such as the tightness of insulating glass windows, and achieve the effect of reducing cable channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

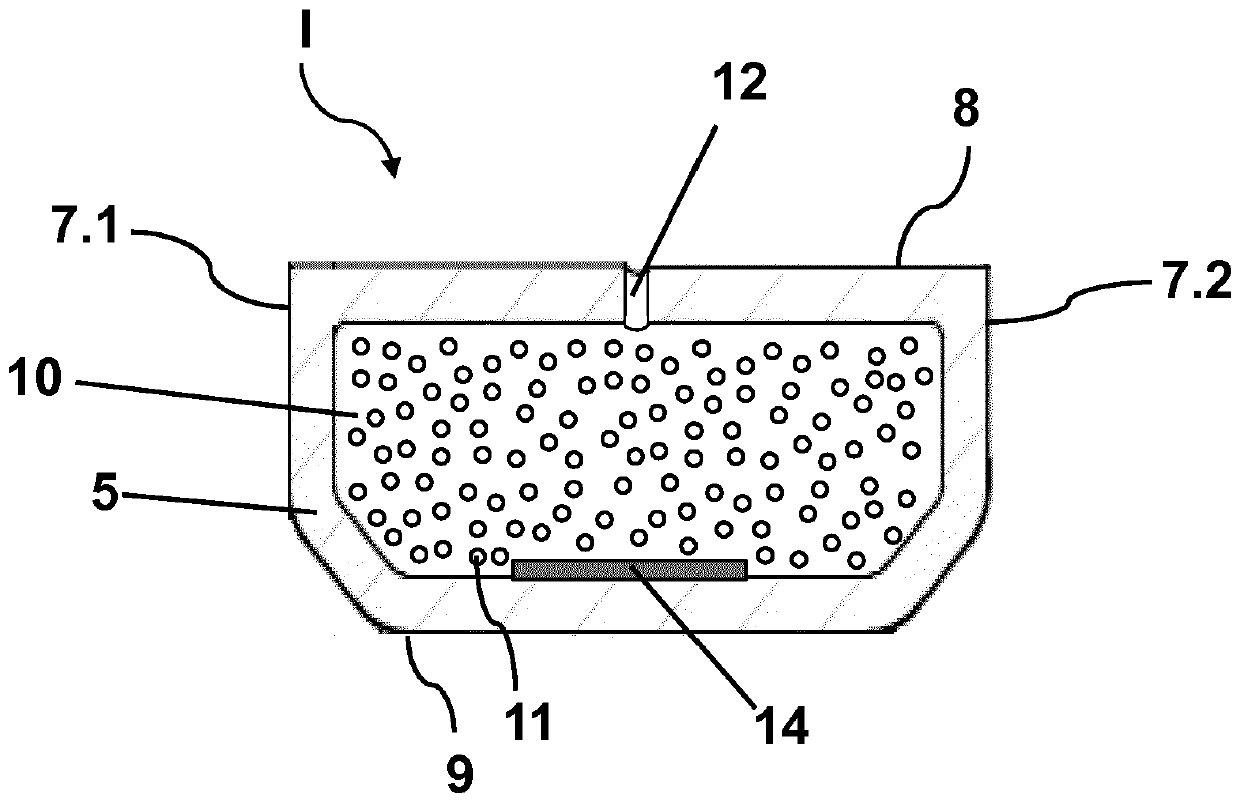

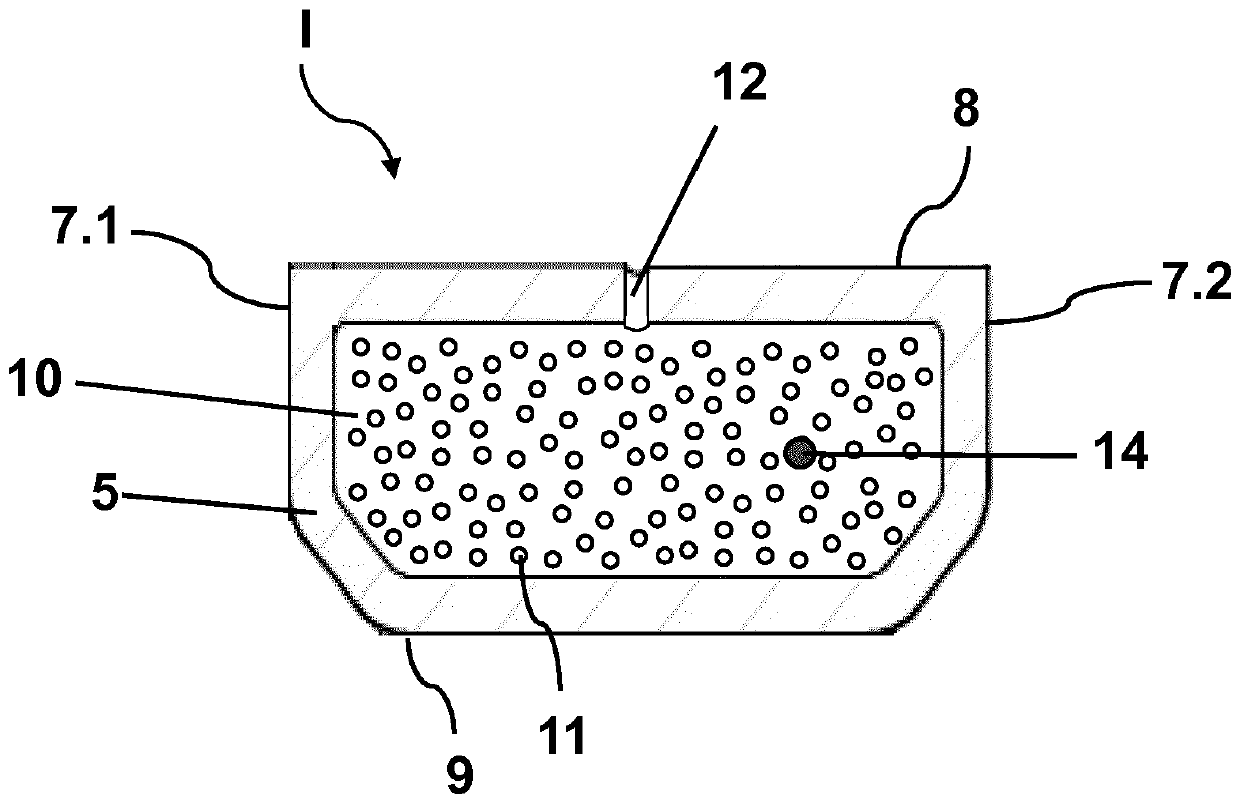

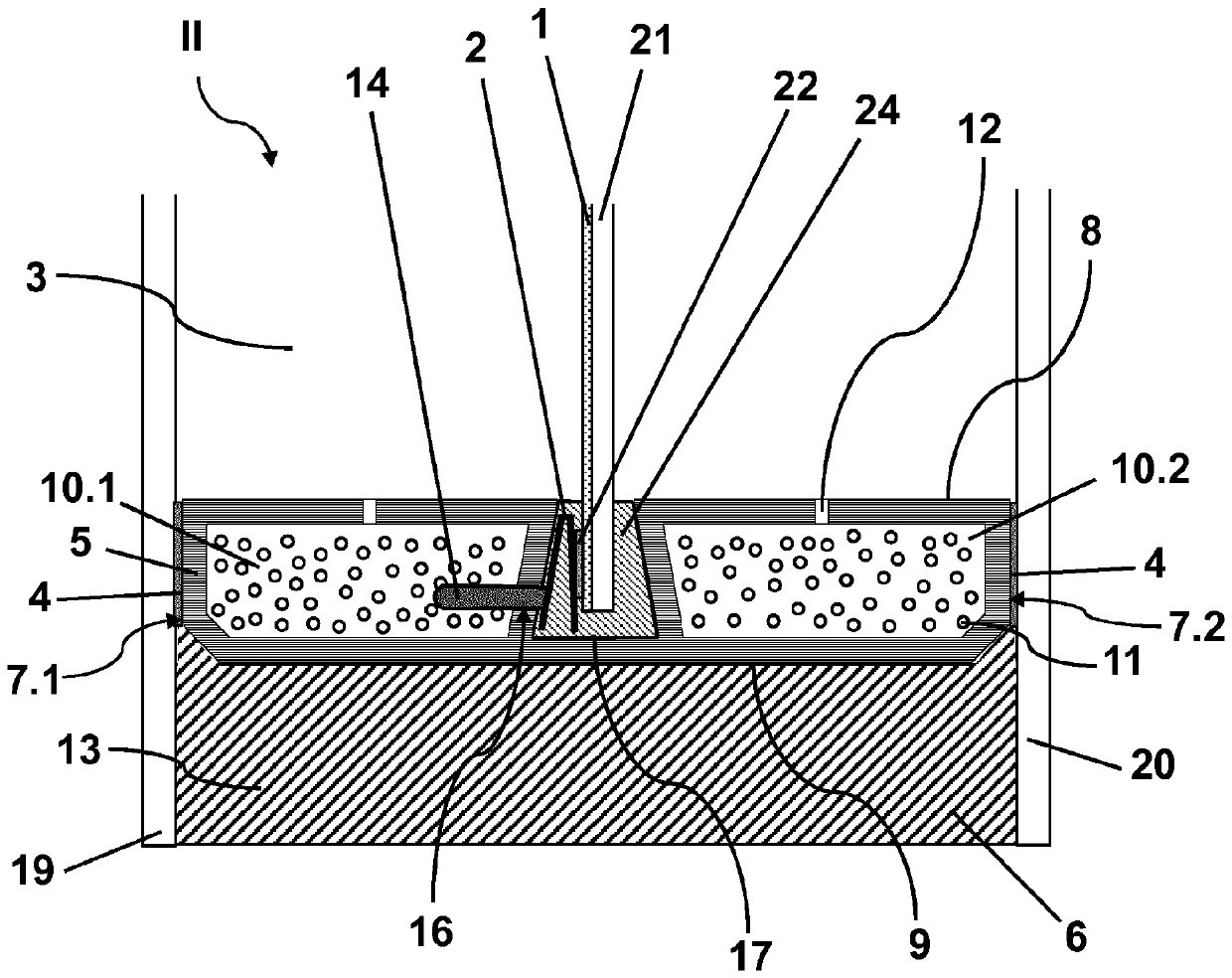

[0121] Figure 1aDepicted is a schematic representation of a spacer I according to the invention comprising a polymer body 5 and an electrical feeder 14 within the body 5 . The polymer body 5 is a hollow body profile comprising two glazing contact surfaces 7.1 and 7.2, the glazing inner surface 8, the outer surface 9 and the hollow chamber 10. The polymer body 5 comprises styrene acrylonitrile (SAN) and approximately 35% by weight glass fibers. The outer surface 9 has an angled shape, wherein the sections of the outer surface adjacent to the glazing contact surfaces 7.1 and 7.2 are inclined at an angle of 30° relative to the glazing contact surfaces 7.1 and 7.2. This improves the stability of the glass fiber reinforced polymer body 5 . The hollow body 10 is filled with a desiccant 11 . Molecular sieves were used as desiccant11. The glazing inner surface 8 of the spacer 1 has openings 12 circumferentially formed at regular intervals along the glazing inner surface 8 to enabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com