Protein purification system and method

A protein purification and protein technology, which is applied in the field of protein purification, can solve problems such as inability to achieve continuous purification, and achieve the effect of substantially improving and improving purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

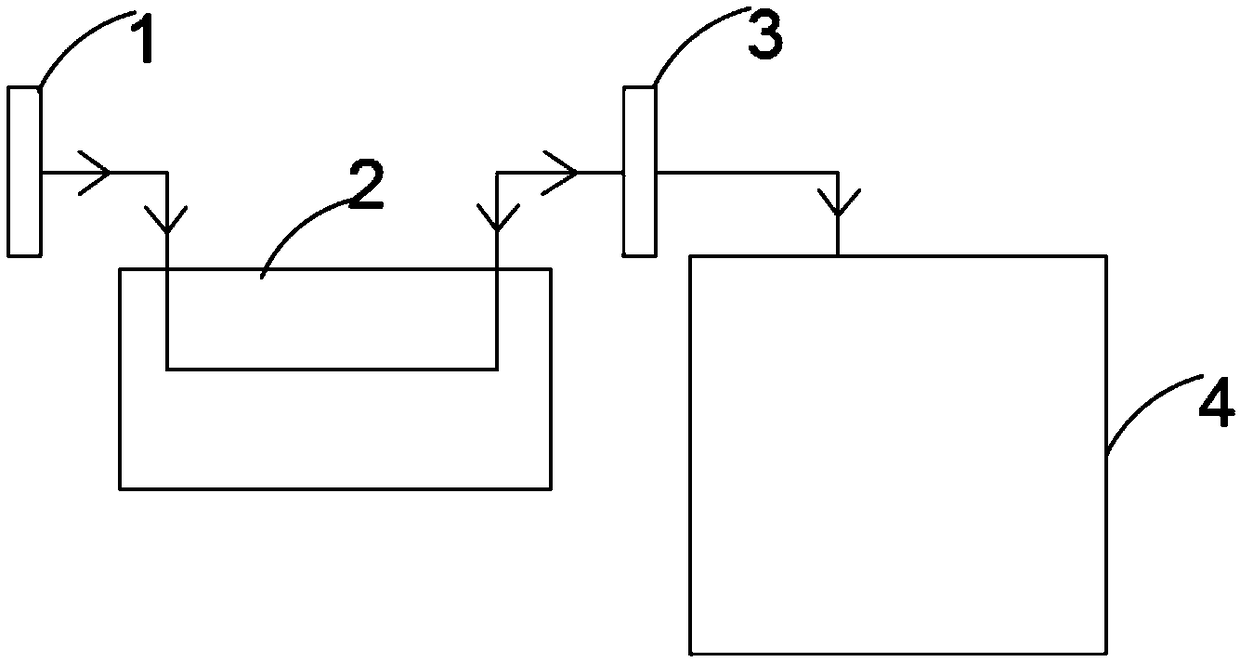

[0050] A protein purification system such as figure 1As shown, the arrow in the figure indicates the flow direction of the protein solution, including the first sterilizing filter 1 (membrane pore size 0.22 μm), heat exchanger 2, second sterilizing filter 3 membrane (pore size 0.22 μm) and protein A affinity chromatography column 4.

[0051] Take Prism A (GE) packing material, Econoline 5 / 250 (Essential life) chromatography column with a diameter of 0.5cm, a column height of 20.5cm, and a column volume of 4ml as an example, and the operating flow rate is 300cm / h.

[0052] The source of the sample is the monoclonal antibody (Mab1) expressed by CHO cells. Pass through the first sterilizing filter, heat exchanger and second sterilizing filter in sequence, wherein the heat exchanger heats the protein solution to 25°C, and then enters the chromatographic column through sterilizing filtration.

[0053] The purification process in the chromatographic column is: wash the chromatogra...

Embodiment 2

[0055] A protein purification system such as figure 1 As shown, the arrow in the figure indicates the flow direction of the protein solution, including the first sterilizing filter 1 (membrane pore size 0.22 μm) connected in sequence), heat exchanger 2, the second sterilizing filter 3 (membrane pore size 0.22 μm) and protein A affinity Column 4

[0056] Taking Praesto Jetted A50 (Purolite) packing material, chromatography column Vantage 11 / 250 (Millipore), diameter 1.1cm, column height 20cm, column volume 20ml as an example, the operating flow rate is 300cm / h.

[0057] The source of the sample is the monoclonal antibody (Mab2) expressed by CHO cells. Pass through the first sterilizing filter, heat exchanger and second sterilizing filter in sequence, wherein the heat exchanger heats the protein solution to 25°C, and then enters the chromatographic column through sterilizing filtration.

[0058] The purification process in the chromatographic column is: wash the chromatographi...

Embodiment 3

[0072] MabSelect SuRe LX, chromatography column Vantage 11 / 250 (Millipore), diameter 1.1cm, column height 20cm, column volume 19.0mL, operating flow rate 220cm / h. The source of the sample is the monoclonal antibody expressed by CHO cells (No. Mab1). Rinse the chromatographic column with 0.2mol / L sodium hydroxide solution of 3CV, then use 5CV of equilibrium liquid (50mM Tris-HCl+150mM NaCl, pH7.4) to equilibrate the chromatographic column; the cell culture harvest liquid after clarification ( HCCF) is loaded onto the chromatographic column, and the loading capacity of the sample is 50g / L; the column bed is washed with 3CV of the equilibrium solution, and the intermediate cleaning buffer (50mM NaAc-HAc+1M NaCl, pH5.5, conductivity 88.5 mS / cm) to wash the column bed, then wash the column bed with 3CV equilibrium solution; then use 3.5CV of eluent (50mM NaAc-HAc, pH3.5) to elute and collect the eluate; finally use 3CV of 0.2mol Rinse the chromatography column with 1 / L sodium hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com