System and method for concentrating organic solvent

An organic solvent and organic solvent-resistant technology, which is applied in the field of concentrated organic solvent systems, can solve the problems of potential safety hazards, high energy consumption, and high equipment investment, and achieve the effects of improved safety, simple structure, and extremely low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

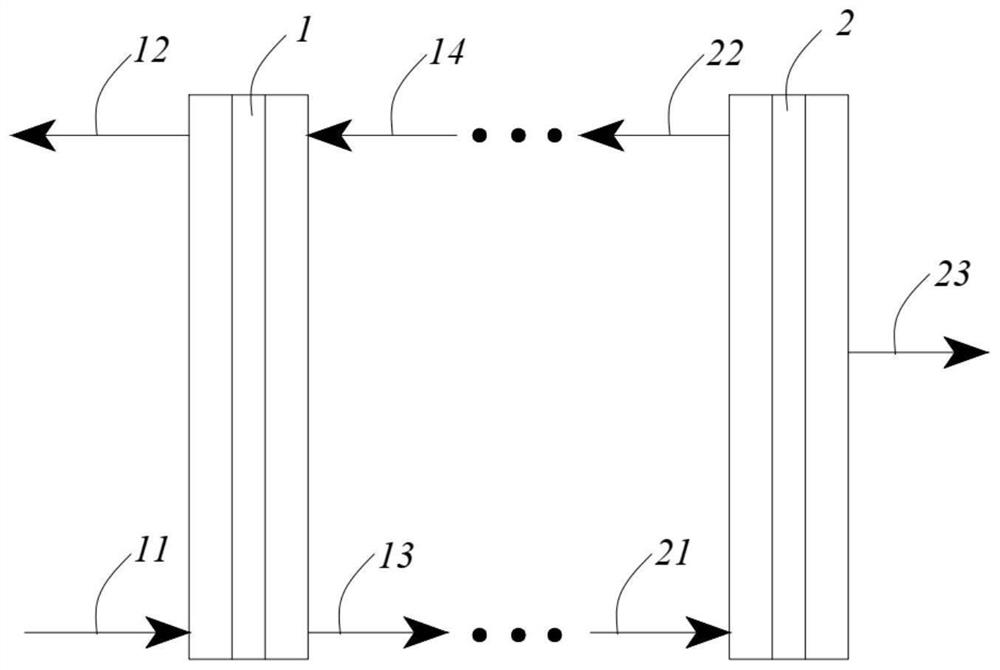

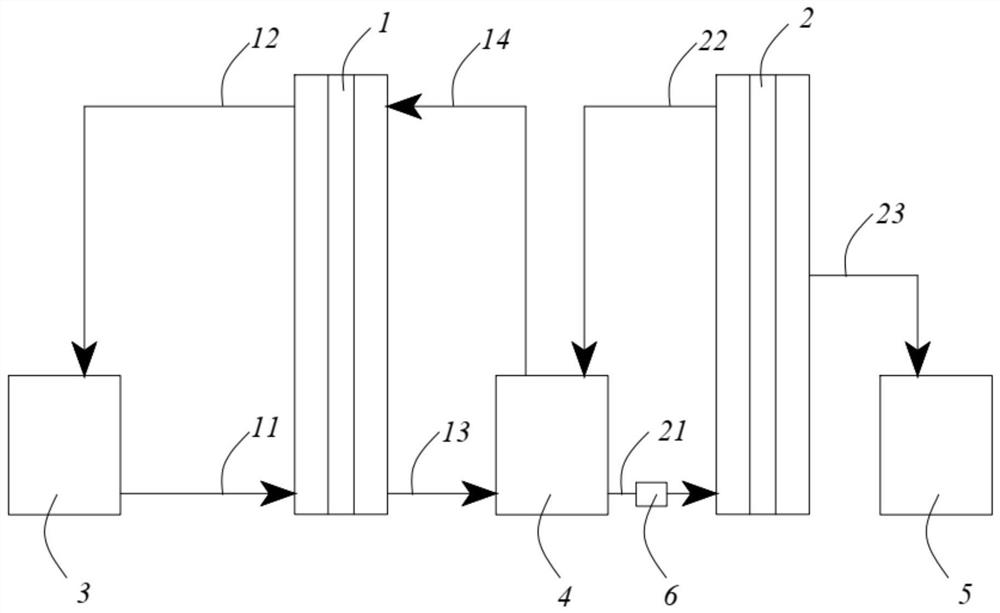

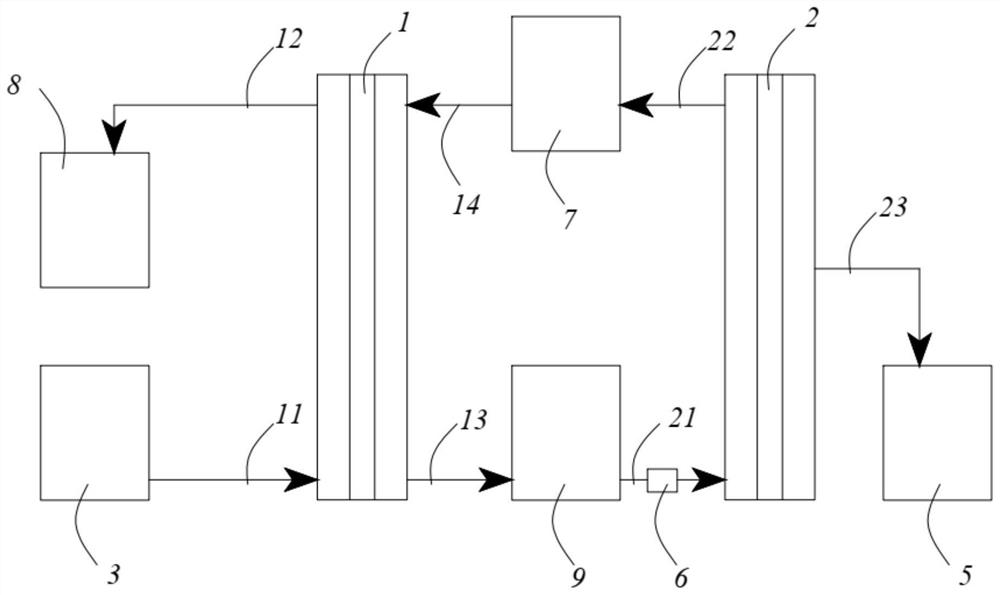

[0023] Because the current osmotic membrane is not resistant to organic solvents, the way of organic solvent concentration is limited, and the forward osmosis membrane made of membrane materials with the function of resisting organic solvents is adopted in this program; with 5% DMF (dimethyl base formamide) aqueous solution is concentrated, while the extract is 1M NaCl solution as an example, the water flux of the forward osmosis membrane is 1-10L / m 2 / hr, reverse salt flux 0.1-5g / m 2 / hr, the rejection rate of organic solvents is greater than 80%.

[0024] Based on above-mentioned forward osmosis membrane, design a kind of method that is used for organic solvent, the step of this method is,

[0025] a) Concentration of the organic solution, the low-concentration organic solvent is passed into one side of the forward osmosis membrane 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com