Pipeline cellulose vertical down welding method

A welding method and cellulose technology, applied in welding equipment, welding accessories, tubular objects, etc., can solve the problems of high construction cost, difficult repair, inconsistent welding seam width, etc., reduce the investment of manpower and material resources, and require high professional quality. , the effect of improving the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the technical solutions of the present invention.

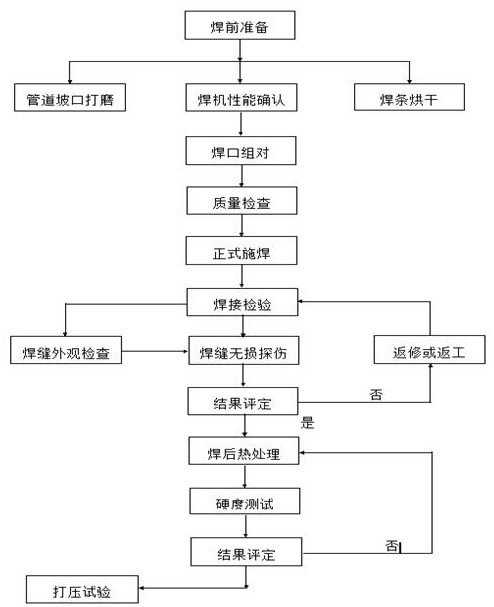

[0030] Such as figure 1 As shown, a kind of pipe cellulose vertical down welding welding method provided by the invention comprises the following steps:

[0031] S1, prepare before welding,

[0032] Grind the groove of the pipe and some areas of the base metal on both sides to remove scale, oil, slag and surface layers that affect the quality of the joint. Usually, the cleaning range is controlled on the groove and the base metal on both sides 20mm area, while smoothing the uneven areas; check whether the performance of the welding machine is good, and dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com