Precast concrete member mold added with flat cover for pressing

A prefabricated component and concrete technology, which is applied in the manufacture of tools, mold auxiliary parts, auxiliary molding equipment, etc., can solve the problems of low production efficiency and air bubbles in prefabricated components, and achieve the effect of reducing the probability of air bubbles, avoiding noise, and ensuring high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

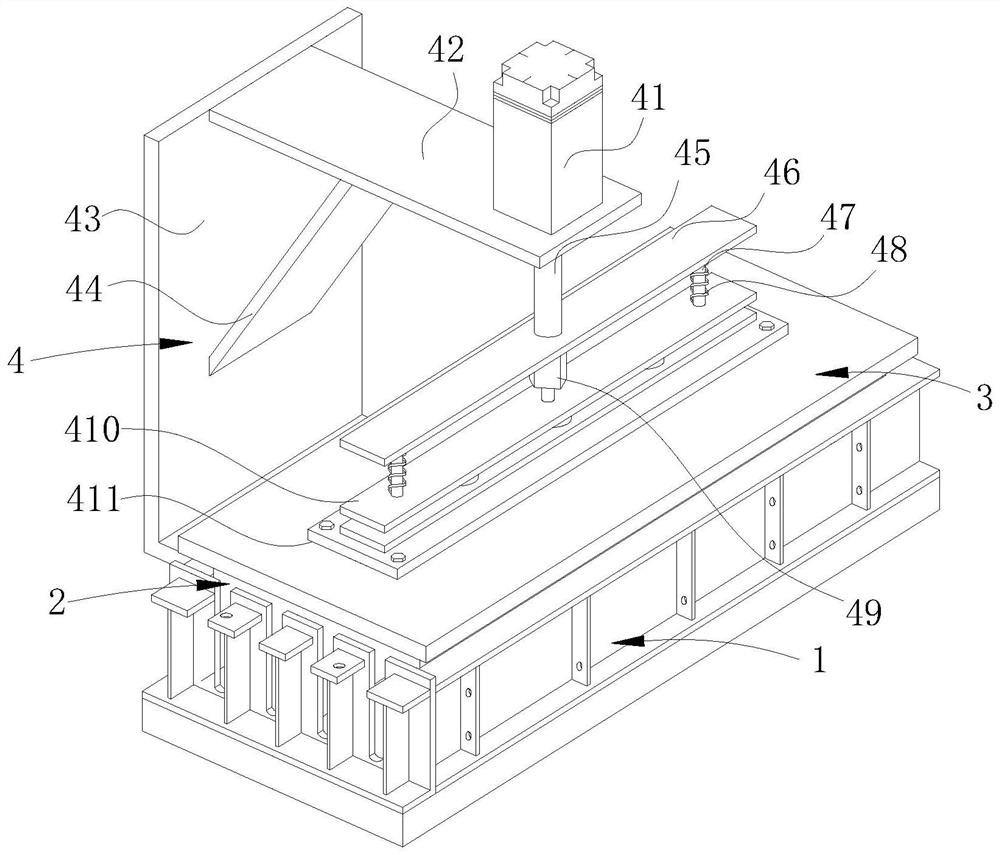

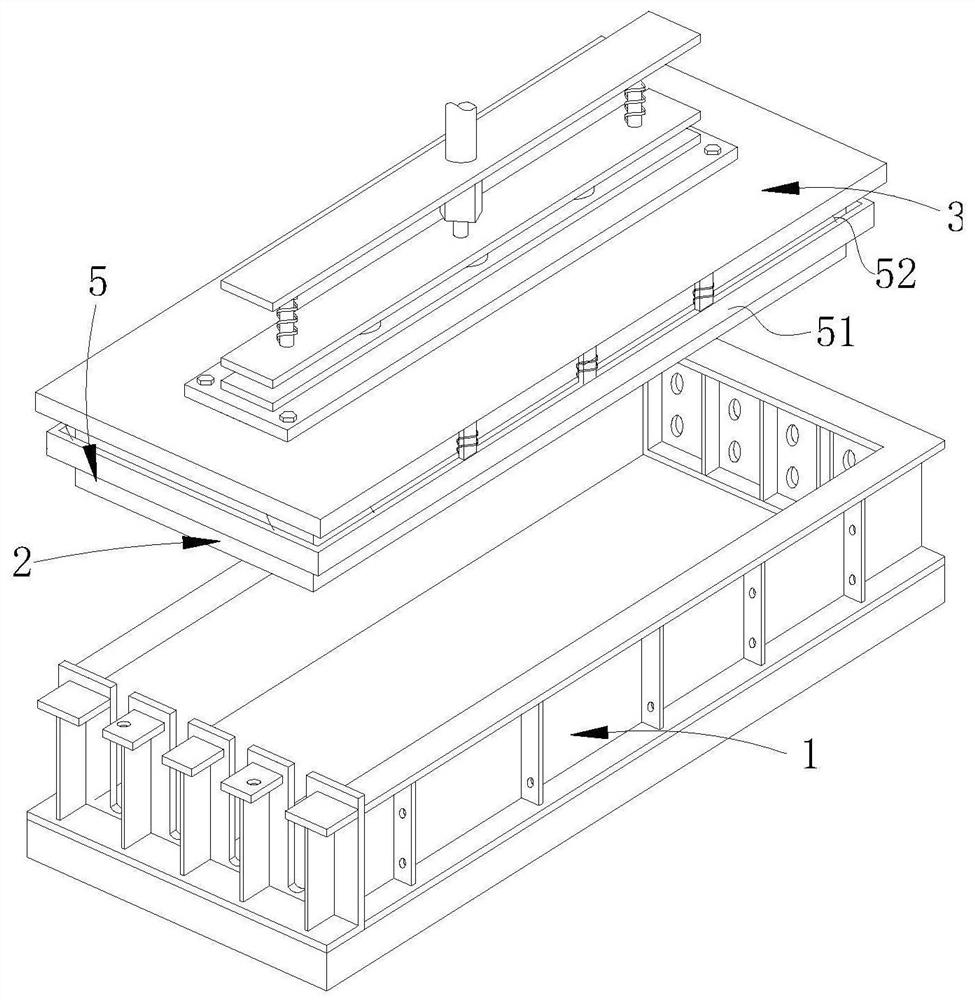

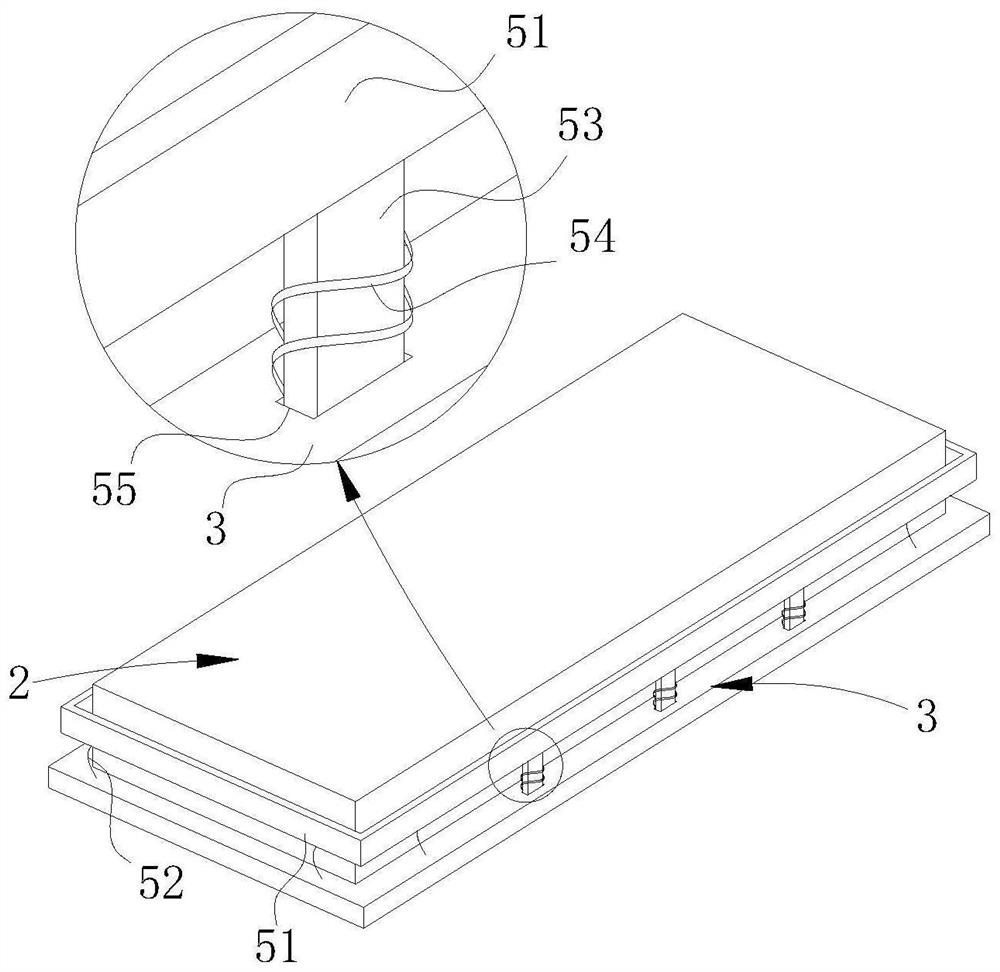

[0034] Attached below Figure 1-5 The present invention is further described with embodiment:

[0035] In this example, see figure 1 , a concrete prefabricated component mold with a flat cover for covering pressure, including a mold body 1, a flat covering cover 2, a No. 1 transverse support plate 3 and a driving vibration mechanism 4, and the flat covering cover 2 is pressed and fastened on the mold body 1, and the flat cover 2 is connected to the lower end surface of the No. 1 transverse support plate 3, and the driving vibration mechanism 4 is arranged on the upper end surface of the No. 1 transverse support plate 3, and is fixed to the side wall of the mold body 1 Connection; the No. 1 transverse support plate 3 is set to a rectangle, and the top surface area of the No. 1 transverse support plate 3 is larger than the opening aperture area of the mold body 1. The setting of the No. 1 transverse support plate 3 can not only play a role in covering the flat cover 2, can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com