Method for enhancing tear resistance of polymer membrane material by using planar silkworm cocoon and composite membrane material thereof

A polymer film and tear-resistant technology, applied in the field of fiber reinforced composite materials, can solve the problems of pure polymer film being unable to effectively disperse stress concentration, notch sensitive fracture failure of pure polymer film, shortening the service life of materials, etc. Ease of shape and size control, improved tear resistance, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

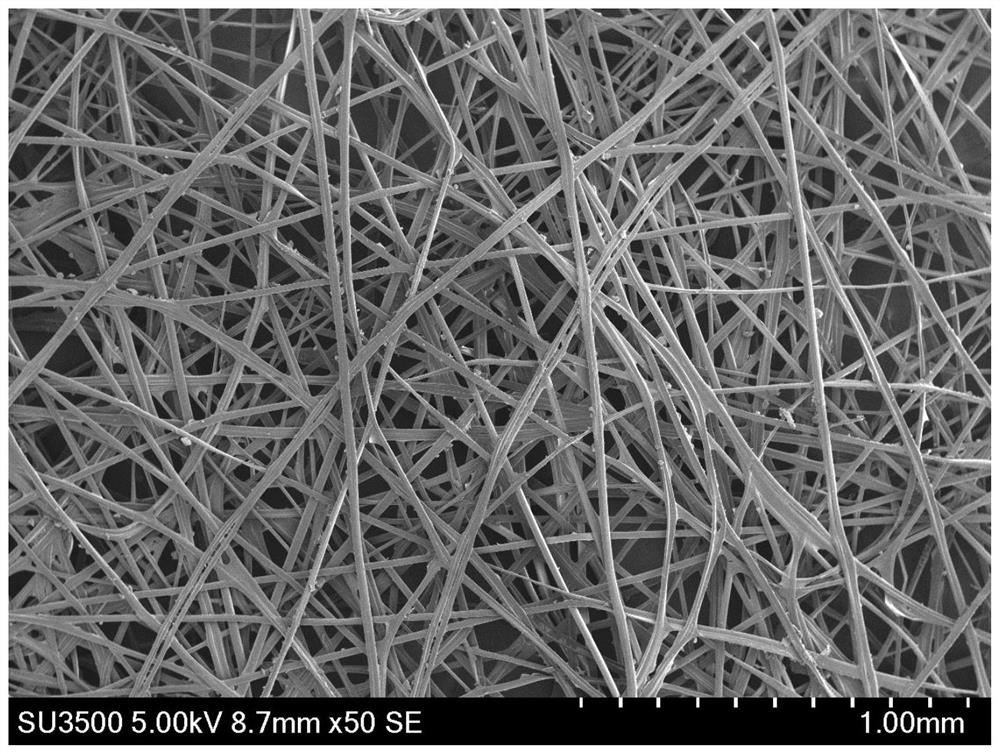

[0031] (1) Preparation of flat silkworm cocoons: 3 cooked silkworms are placed on a circular flat plate with a diameter of 20 cm to spin silk, so that the ratio of the number of cooked silkworms to the area of the flat plate is about 1 (head): 105 (cm 2 ). Finally, a circular planar cocoon with a diameter of 20 cm is obtained, and its fiber network structure is as follows: figure 1 shown.

[0032] (2) Mixed polymer solution: cut the planar cocoon obtained in step (1) into a size with a length*width of 3.5cm*3.5cm, and place it in a groove with a depth of 0.9mm (length*width*depth is 3.5cm *3.5cm*0.9mm), then pour epoxy resin (Epoxy resin, 3016LV, Shenzhen Huasheng Tongchuang Technology Co., Ltd.) into the groove and completely immerse the plane cocoon;

[0033] (3) Remove air bubbles: extract the mixed system obtained in step (2) by a vacuum pump for 5 minutes;

[0034] (4) Curing: The mixed system obtained in step (3) was cured in a constant temperature oven at a curing ...

Embodiment 2

[0038] (1) Preparation of flat silkworm cocoons: 3 cooked silkworms are placed on a circular flat plate with a diameter of 20 cm to spin silk, so that the ratio of the number of cooked silkworms to the area of the flat plate is about 1 (head): 105 (cm 2 ). Finally, a circular plane cocoon with a diameter of 20 cm is obtained.

[0039] (2) Mixed polymer solution: cut the planar cocoon obtained in step (1) into a size with a length*width of 3.5cm*3.5cm, and place it in a groove with a depth of 0.9mm (length*width*depth is 3.5cm *3.5cm*0.9mm), then pour polydimethylsiloxane (PDMS, Sylgard 184, Dow Corning, USA) into the groove and completely immerse the plane cocoons;

[0040] (3) Remove air bubbles: extract the mixed system obtained in step (2) by a vacuum pump for 10 minutes;

[0041] (4) Curing: The mixed system obtained in step (3) was cured in a constant temperature oven, the curing temperature was 60° C., and the curing time was 4 hours.

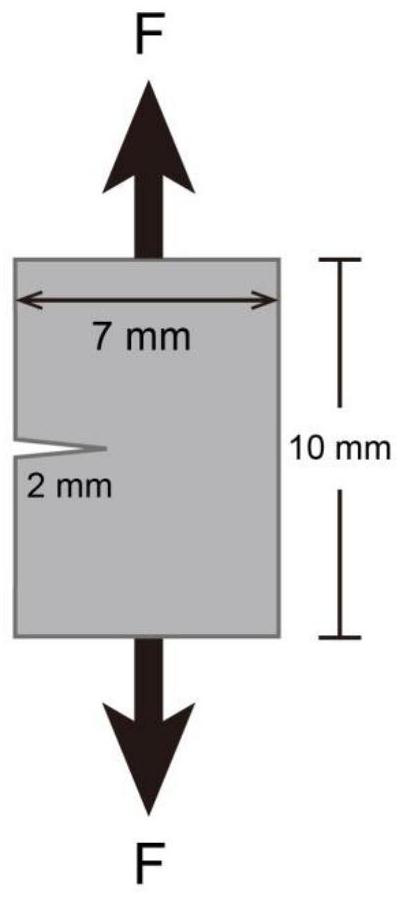

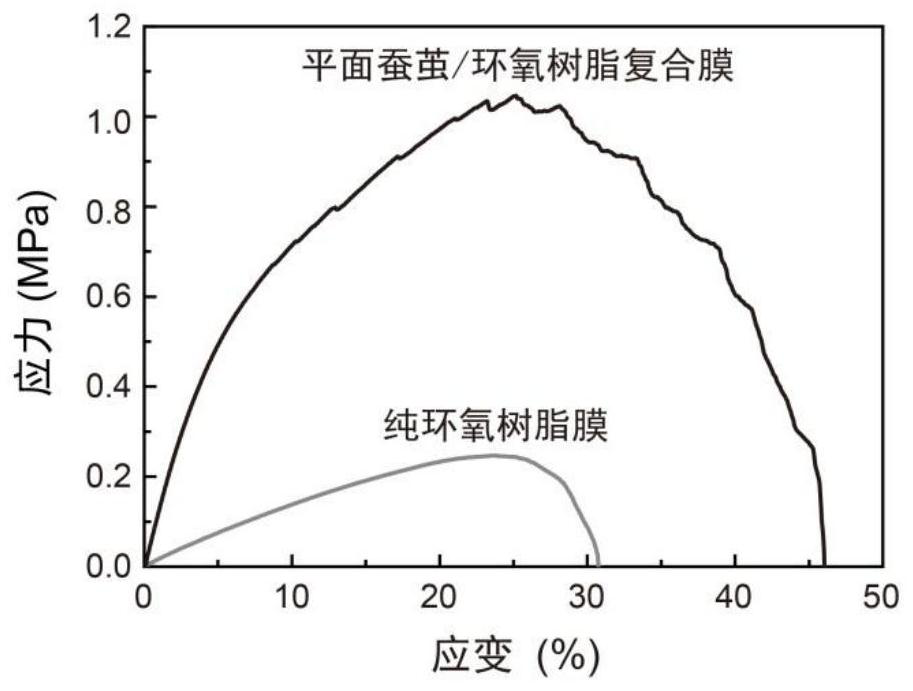

[0042] (5) Performance charac...

Embodiment 3

[0045](1) Preparation of planar silkworm cocoons: 6 cooked silkworms are placed on a circular plate with a diameter of 20 cm to spin silk, so that the ratio of the number of cooked silkworms to the area of the plate is about 1 (head): 52.5 (cm 2 ). Finally, a circular plane cocoon with a diameter of 20 cm is obtained.

[0046] (2) Mixed polymer solution: cut the planar cocoon obtained in step (1) into a size with a length*width of 3.5cm*3.5cm, and place it in a groove with a depth of 0.9mm (length*width*depth is 3.5cm *3.5cm*0.9mm), then pour epoxy resin (Epoxy resin, 3016LV, Shenzhen Huasheng Tongchuang Technology Co., Ltd.) into the groove and completely immerse the plane cocoon;

[0047] (3) Remove air bubbles: extract the mixed system obtained in step (2) by a vacuum pump for 5 minutes;

[0048] (4) Curing: The mixed system obtained in step (3) was cured in a constant temperature oven at a curing temperature of 55° C. and a curing time of 12 hours.

[0049] (5) Perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com