Preparation method of 17-4PH stainless steel base

A stainless steel and base technology, which is applied in the field of preparation of 17-4PH stainless steel base, can solve the problems of difficulty in improving product strength and plasticity at the same time, surface cracking, hot brittleness, poor corrosion resistance, etc., and achieves low cost and corrosion resistance. Strong, corrosion resistance improvement effect

Pending Publication Date: 2020-09-01

SHANDONG JIANZHU UNIV

View PDF9 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0012] Aiming at the limited improvement of the performance of the 17-4PH base in the above-mentioned prior art, surface cracking and thermal brittleness are prone to occur during the forging process, it is difficult to improve the product strength and plasticity at the same time, poor weldability, poor corrosion resistance and cumbersome process, etc., this paper The purpose of the invention is to provide a method for preparing a 17-4PH stainless steel base. The present invention combines composition design, smelting, casting, multiple forging and solid solution aging. Compared with the prior art, the present invention’s The technical solution can provide a convenient and fast preparation process for the 17-4PH base, a perfect forging scheme, improve the preparation efficiency, reduce cracking, meet the corrosion resistance in complex environments while ensuring strength and toughness, and comprehensively improve 17-4PH The mechanical and performance properties of the base can better meet the needs of industrial production and realize large-scale production

Method used

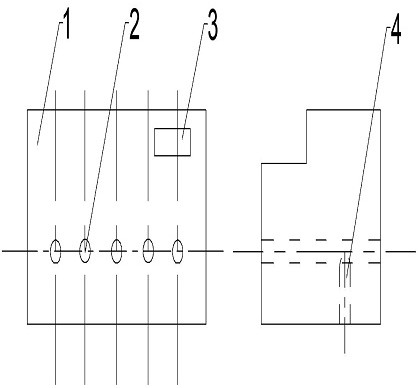

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0030] It should be noted that the following detailed description is exemplary and intended to provide further explanation of the present invention. Unless defined otherwise, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the field of base manufacturing and heat treatment and specifically relates to a preparation method of a 17-4PH stainless steel base. The preparation method of the 17-4PH stainless steel base mainly comprises the following step of manufacturing the 17-PH base by using a component design, smelting, casting, multiple forging and solution and aging combined treatment mode. According to the technical scheme of the preparation method of the 17-4PH stainless steel base, the content of delta-ferrite in the base can be preferably controlled; multiple forging is conducive to the formation of a high density dislocation wall in the base; the alloy micro-structure refining effect is obvious; phenomena of surface crack and hot shortness in the forging process are avoided; and the strength of the 17-4PH base is enhanced. Meanwhile, a convenient and rapid 17-4PH base preparation process is provided, the preparation efficiency is enhanced, the corrosion resistance performanceunder a complicated environment is met while the strength and the tenacity are guaranteed, the use performance of the 17-4PH base is comprehensively improved, demands of industrial production can be preferably satisfied, and scale production is realized.

Description

technical field [0001] The invention relates to the field of base manufacturing and heat treatment, in particular to a method for preparing a 17-4PH stainless steel base. Background technique [0002] The information disclosed in the background of the present invention is only intended to increase the understanding of the general background of the present invention, and is not necessarily to be regarded as an acknowledgment or in any form to imply that the information constitutes the prior art known to those of ordinary skill in the art; recent years In the past, with the development of my country's offshore oil and gas resources, high-strength stainless steel materials have been widely used in underwater production systems such as subsea oil and gas transmission systems, offshore platform systems, and offshore transportation systems. Due to the complexity and particularity of the marine service environment, there are still risks of complex and large-scale material stress and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/02C22C38/04C22C38/42C22C38/44C22C38/48C21D8/00

CPCC21D8/005C21D2211/004C21D2211/005C21D2211/008C22C38/02C22C38/04C22C38/42C22C38/44C22C38/48

Inventor 景财年吴聪林涛赵顺治叶道珉雷启腾刘磊张志浩

Owner SHANDONG JIANZHU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com