A construction method and auxiliary device for removing segment in a hole

A construction method and technology of segment assembling machine, which are applied in vertical shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problem that segment connecting pins are not easy to be disassembled, etc., so as to improve construction safety factor, reduce downtime, and promote high promotion. effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0047] Embodiment 2: A construction method for removing segments in a hole, the steps are as follows:

[0048] S1: Set the segment to be removed as the target segment 1, and set the propulsion cylinder located in front of the target segment 1 and corresponding to the target segment as the target propulsion cylinder 5; the central axis of the target propulsion cylinder 5 and the target segment The center line of the center line coincides, the propulsion cylinder is located in the shield body 4, and the layout of the target propulsion cylinder and the target segment is the existing segment laying method;

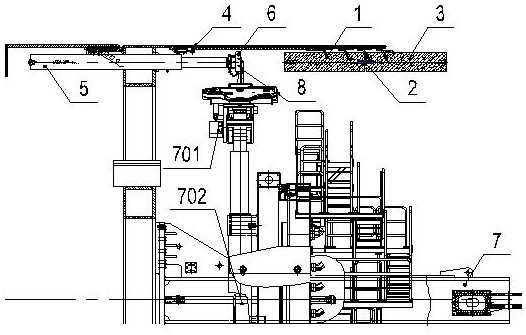

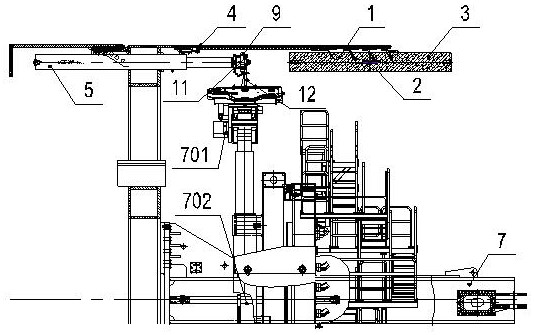

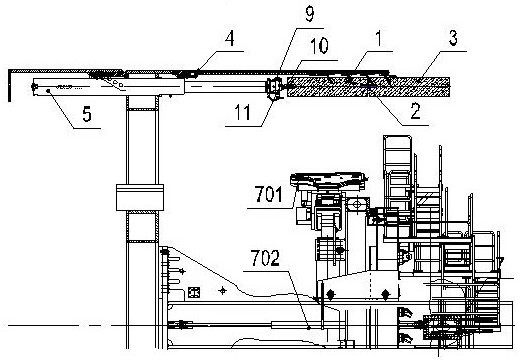

[0049] S2: Install the first tooling on the suction cup 701 of the segment assembly machine 7, the first tooling 8 is detachably connected to the suction cup for supporting the boots, and then push the target into the oil cylinder 5 through the segment assembly machine 7 and the first tooling 8 The stay shoe 6 on the removal, such as figure 1 shown.

[0050] S3: Disassemble ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com