Passenger vehicle PM test system and method

A test method and technology for passenger vehicles, applied in the field of in-vehicle environmental health and environmental protection, can solve problems such as inapplicability, difficulty in complete vehicle, aerosol protection and filtration testing, etc., to achieve difficult adsorption, increase reliability, improve efficiency and The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

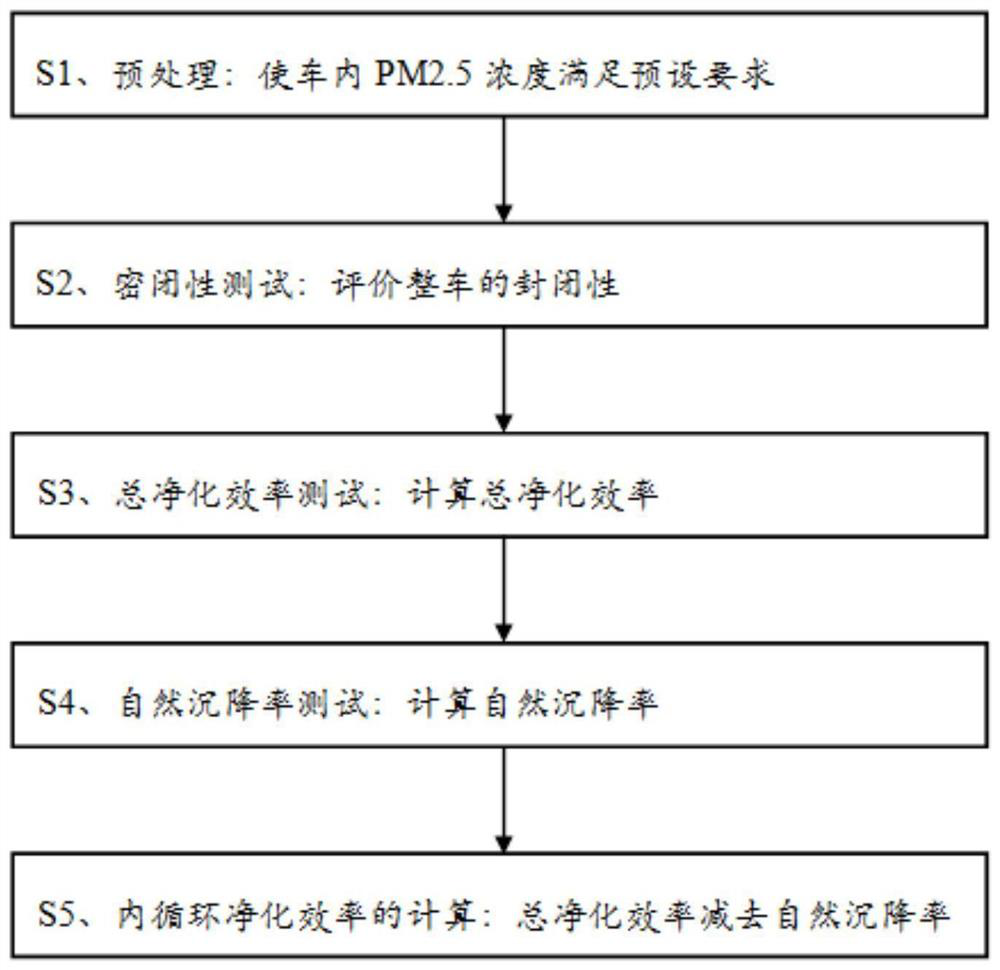

[0055] An embodiment of the PM test method of a passenger car vehicle according to the present invention is basically as attached figure 1 Shown: Including steps: S1. Pretreatment: make the temperature and humidity of the environmental chamber and the concentration of PM2.5 in the vehicle meet the preset requirements; S2. Airtightness test: evaluate the airtightness of the whole vehicle by increasing the concentration of PM2.5 in the car ; S3, total purification efficiency test: calculate the total purification efficiency; S4, natural sedimentation rate test: calculate the natural sedimentation rate; S5, calculation of internal circulation purification efficiency: internal circulation purification efficiency = total purification efficiency - natural sedimentation rate.

[0056] In this embodiment, a NaCl aerosol generating device is used as the source of particle pollution. The NaCl aerosol particles produced by the device have a particle mass median diameter of 0.6um, which ca...

Embodiment 2

[0073] The only difference from Example 1 is that the particulate matter simulation generating device uses cigarette smoke as the simulated dust source of particulate matter pollution, uses an automatic cigarette lighter to send the smoke into the environmental chamber through positive pressure, and the particle size distribution of the cigarette smoke is 0.1-0.75um. The particle dust source is introduced into the environmental cabin, and through the air mixing and circulation system of the environmental cabin, a relatively stable particulate pollution environment is created. The particle concentration change in the vehicle is tested within 0.5 hours. Through data calculation, the barrier and protection performance of the vehicle to particulate matter is investigated. The particle flow rate of the cigarette smoke generator is generally 1-5L / min. Due to the fast combustion speed, it is suitable for producing particle pollution concentrations in a large environment; and the partic...

Embodiment 3

[0075] The only difference from Embodiment 1 is that in this embodiment, the aerosol is formed by the smoke smoked by the driver, who sits in the driving seat. In the process of smoking, the generation of aerosol can be divided into two parts: first, the smoke that the driver spits out when he smokes; second, the smoke that diffuses from the natural combustion of the cigarette when the driver does not smoke. Therefore, in the test environment in this implementation, in order to ensure that the test results are closer to the actual situation, it is necessary to make corresponding corrections to the particle generation process.

[0076] In this implementation, the driver sits in the driving position and smokes. When he takes a puff of cigarette, he spits out the smoke and puts the burning cigarette in the ashtray on the right hand side; Cigarettes in the ashtray on the right hand side, cycle through. In order to properly simplify the test process, it can be considered that ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com