Improved asphalt dumping melting equipment

A kind of melting equipment and an improved technology, which is applied in the direction of emptying containers, bottle filling, roads, etc., can solve the problems of asphalt waste, asphalt not being removed, and barrel movement is not smooth, so as to prevent asphalt residue, save transportation costs, Effect of improving bitumen debarrel and melting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

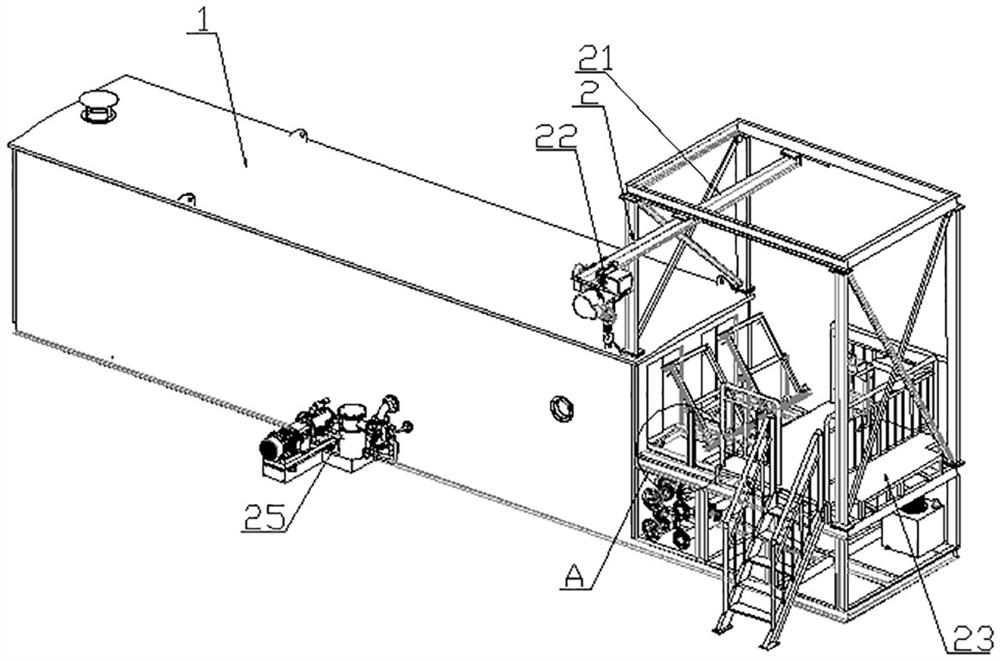

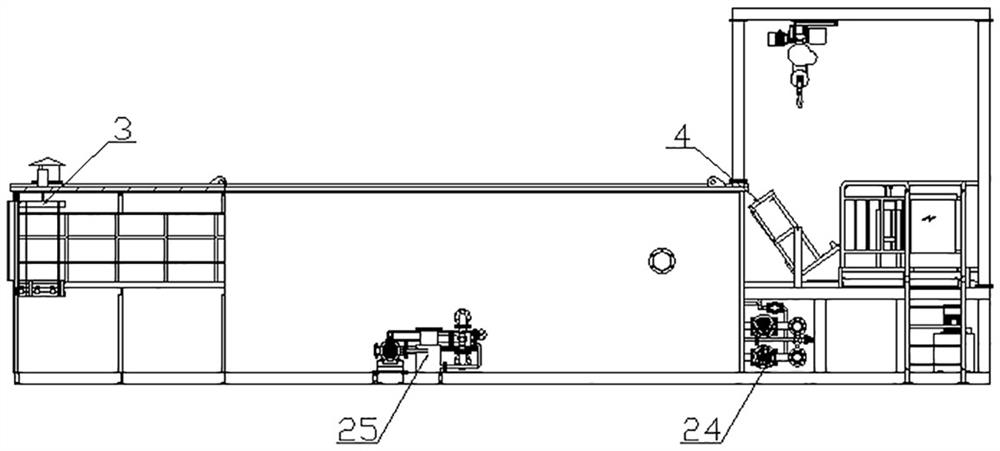

[0022] Referring to the figure, an improved bitumen debarrel melting equipment according to the present invention is composed of a heating box 1 and an operating area 2 .

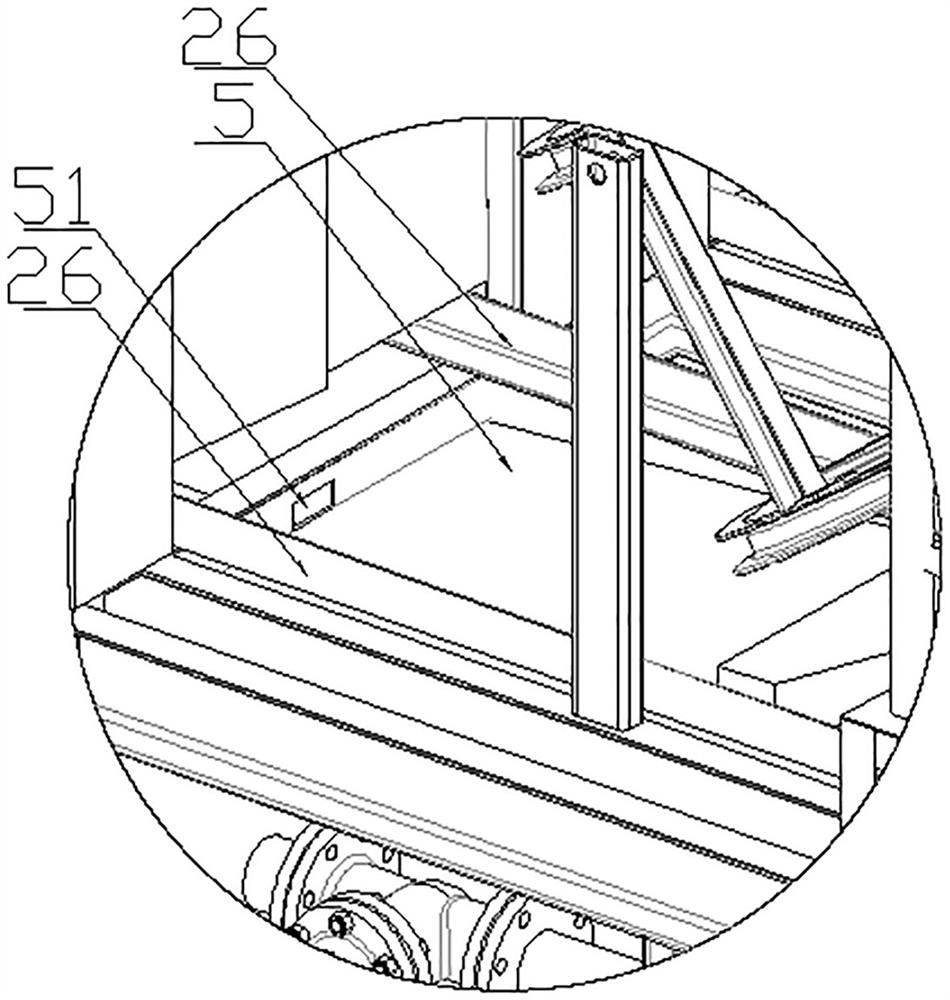

[0023] The heating box 1 is provided with an asphalt delivery pump group 25 to realize internal asphalt circulation and external supply; in the operation area 2, it includes a group of aerial crane brackets, and the top of the aerial crane brackets is provided with a moving track 21 And the crane 22 can realize the hoisting of the asphalt drum from the outside to the inside; on the workbench 23, a drum turner 4 is arranged near the heating box 1, and the asphalt drum can be placed on the drum turner 4 to realize the turning of the asphalt drum. The present invention realizes the overturning of asphalt bucket by such as figure 2 and Figure 8 The shown barrel turner 4 is realized, and the barrel turner 4 includes a bottom tray 43, an arc-shaped bracket 42 is fixed on the bottom tray 43, and a top supportin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com