Powerful squeezing sludge dewatering device

A sludge dehydration and extrusion dehydration technology, applied in water/sludge/sewage treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of difficulty in meeting market demand, low dehydration efficiency, etc., to improve the dehydration effect , Improve dehydration efficiency and avoid the effect of contamination with water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is attached Figure 1-6 The application is described in further detail.

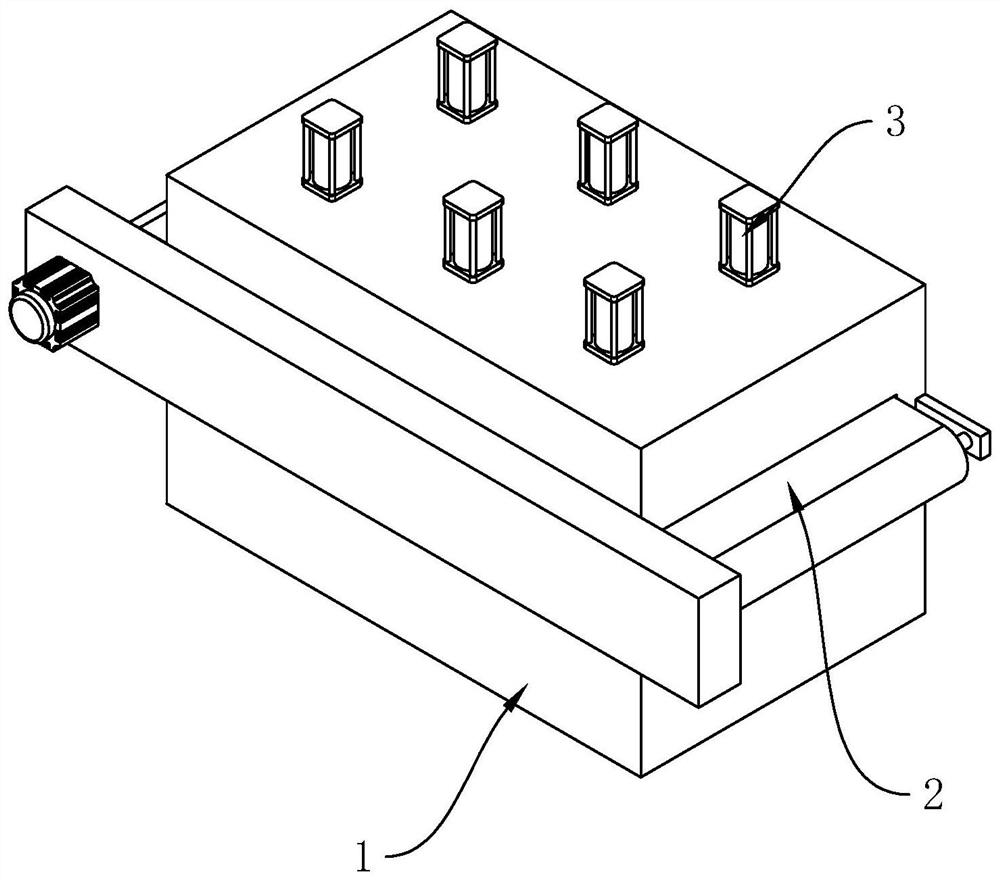

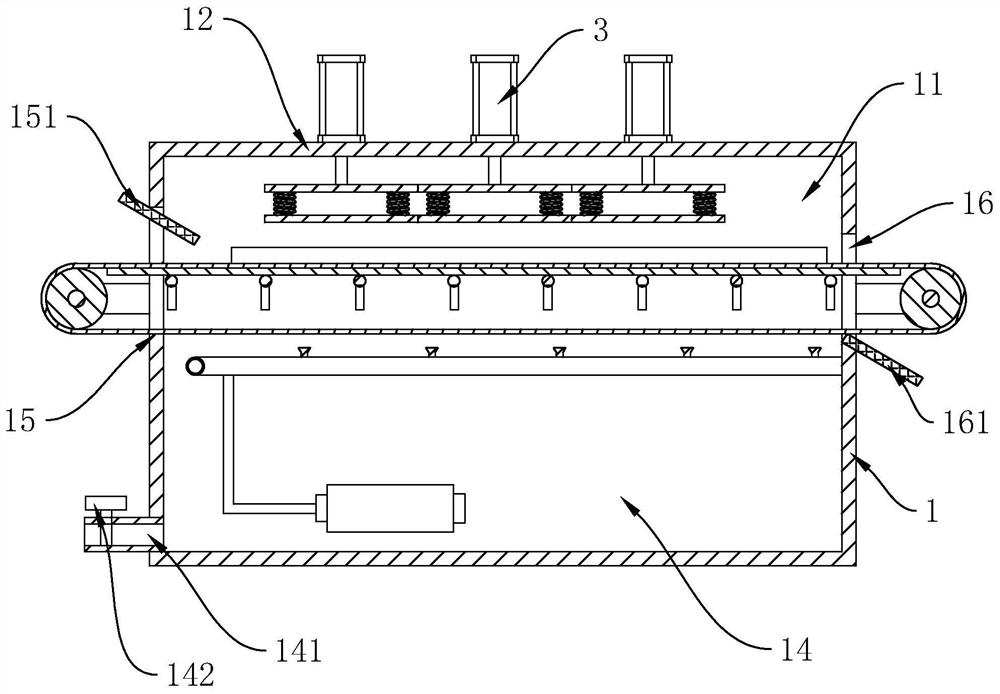

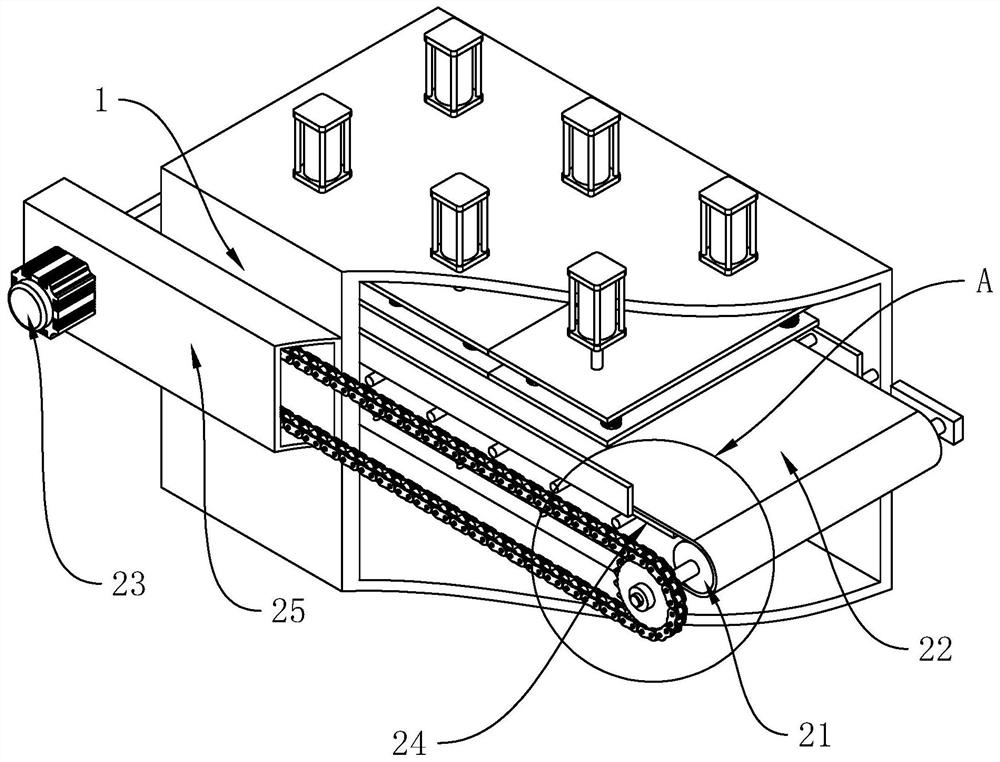

[0039] The embodiment of the present application discloses a device for dehydrating strongly squeezed sludge. refer to figure 1 , including a frame 1, a conveying device 2 and a filter press device 3, the frame 1 is installed on the ground for the main supporting function and sewage collection, and the conveying device 2 is installed on the frame 1 for continuous conveying Sludge, the filter press device 3 is provided with several pieces, each piece of filter press device 3 is installed on the frame 1 and is located directly above the conveying device 2, and each piece of filter press device 3 is used for the sewage conveyed on the conveying device 2 The mud is extruded and dehydrated.

[0040] refer to figure 1 with figure 2 , the frame 1 is box-shaped, and the left and right sides of the frame 1 are vertically provided with partitions 11, and the two partitions 11 extend alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com