Preparation method of polyhexamethylene guanidine hydrochloride

A technology of polyhexamethylene guanidine hydrochloride and guanidine hydrochloride, which is applied in the field of polymer preparation, can solve the problems of high energy consumption, increased cost and the like, and achieves the effects of high yield, avoiding volatilization, and few raw materials and auxiliary materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

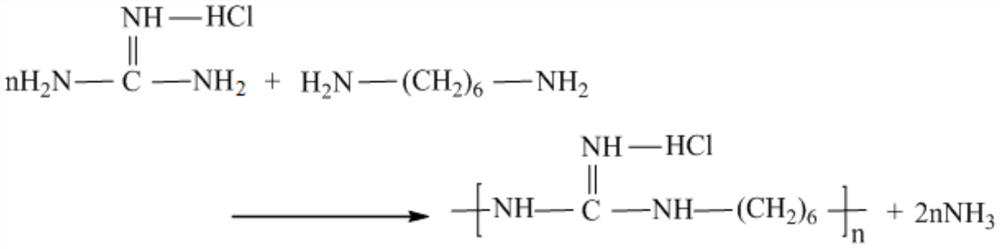

[0028] The preparation method of polyhexamethyleneguanidine hydrochloride provided by the invention comprises the following steps:

[0029] Step 1, put hexamethylenediamine and guanidine hydrochloride into the reactor in a certain proportion, stir and heat until completely dissolved and fully mixed;

[0030] Step 2, the temperature in the reactor is raised to 155-165° C., and the temperature is kept for 0.5-1.5 hours;

[0031] Step 3, the temperature in the reactor rises to 165-175°C, and after 1.5-2.5 hours of heat preservation, add to the reactor every 0.3-0.7 hours. Add a certain amount of deionized water into the reactor every 0.5 hours, and add 2 to 6 times in total;

[0032] Step 4, the temperature in the reactor is raised to 175-185° C., and the temperature is kept for 0-1 hour;

[0033] Step 5, stop heating the reactor, and add a certain amount of deionized water into the reactor, so that the temperature in the reactor drops to 55-65°C;

[0034] Step 6, transferring...

Embodiment 1

[0052] Put hexamethylenediamine and guanidine hydrochloride in a molar ratio of 1.05:1 into the reactor, stir and heat until completely dissolved and fully mixed; the reactor is heated so that the temperature in the reactor rises to 155°C, and the temperature is kept for 1.5 hours; the reactor Continue heating so that the temperature in the reactor rises to 165° C. After 2.5 hours of heat preservation, add a certain amount of deionized water to the reactor every 0.7 hours for a total of 6 times; the reactor continues to heat so that the temperature in the reactor rises to 175°C, heat preservation for 1 hour; the reactor stopped heating, and deionized water with a mass equivalent to the total mass of hexamethylenediamine and guanidine hydrochloride was added to the reactor, so that the temperature in the reactor dropped to 65°C; Transfer the material to a dilute decolorization kettle for decolorization and filtration; slowly add dilute hydrochloric acid to adjust the pH to 7-8, ...

Embodiment 2

[0054] Put hexamethylenediamine and guanidine hydrochloride in a molar ratio of 1.05:1 into the reactor, stir and heat until completely dissolved and fully mixed; the reactor is heated so that the temperature in the reactor rises to 160°C, and the temperature is kept for 1 hour; the reactor Continue heating so that the temperature in the reactor rises to 170° C. After 2 hours of insulation, add quality to the reactor every 0.5 hour to add 1.2% deionized water that is the total mass of hexamethylenediamine and guanidine hydrochloride added in step 1, Added 4 times in total; the reactor continued to heat, so that the temperature in the reactor rose to 180°C, and was kept warm for 0.5 hours; the reactor was stopped heating, and deionized water with a mass equivalent to the total mass of hexamethylenediamine and guanidine hydrochloride was added to the reactor within the reactor so that the temperature in the reactor drops to 60°C; transfer the material in the reactor to a dilute d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com