Method for producing fresh-scent type sugarcane wine by using pure sugarcane juice

A technology of sugarcane juice and fragrance type, which is applied in the field of production of fragrance type sugarcane wine, which can solve the problems of difficulty in adapting to the enjoyment of high-quality wine, low alcohol content, and weak taste, so as to achieve pleasant aroma, good aroma and taste, and shorten the fermentation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

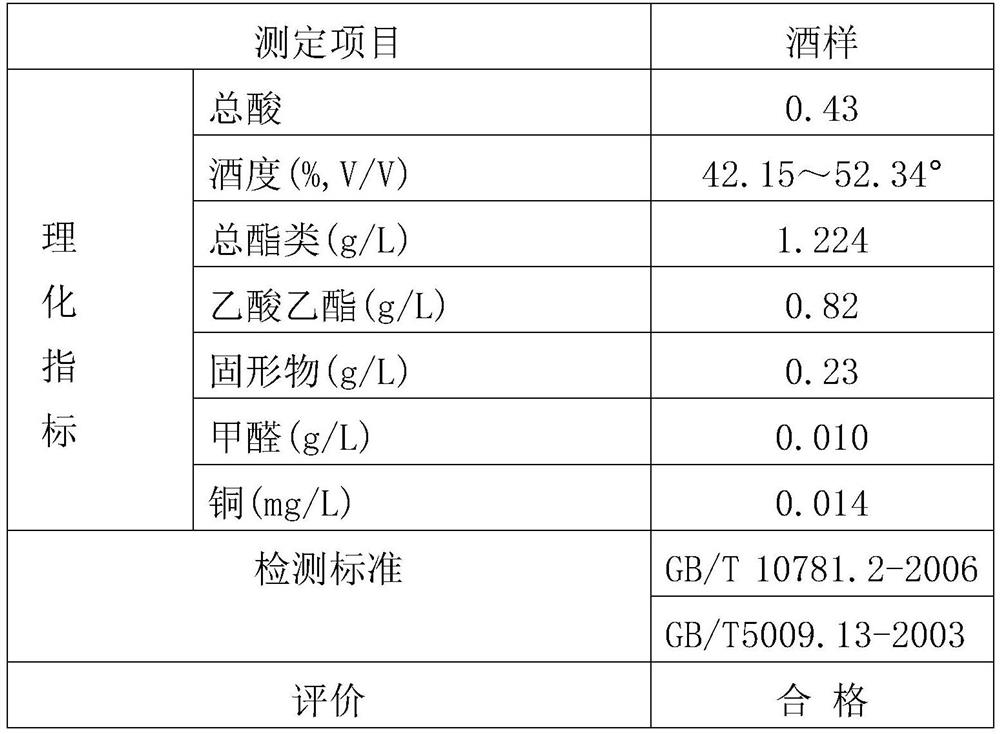

Examples

Embodiment 1

[0022] The method for utilizing pure sugarcane juice to produce fragrant sugarcane wine is characterized in that: comprising the following steps:

[0023] S1), take fresh sugarcane without mildew, use a cutting machine to cut into sections, and squeeze the juice to obtain sugarcane juice and bagasse;

[0024] S2), the sugarcane juice is heated in an iron pan, put into a container after boiling and cool for subsequent use;

[0025] S3), select a container, dilute the bagasse with water, add Saccharomyces cerevisiae, and ferment for more than 48 hours. After the alcohol content of the cane juice reaches 5-6°, put it in a heating tank and heat it to 55°C, and filter out the bagasse , to obtain a filtrate; the weight ratio of bagasse to Saccharomyces cerevisiae is 2000:1. Saccharomyces cerevisiae is prepared by mixing Saccharomyces cerevisiae xiaoqu, Saccharomyces cerevisiae Daqu and Saccharomyces cerevisiae, and the mass ratio between Saccharomyces cerevisiae xiaoqu, Saccharomyc...

Embodiment 2

[0035] The method for utilizing pure sugarcane juice to produce fragrant sugarcane wine is characterized in that: comprising the following steps:

[0036] S1), take fresh sugarcane without mildew, use a cutting machine to cut into sections, and squeeze the juice to obtain sugarcane juice and bagasse;

[0037] S2), the sugarcane juice is heated in an iron pan, put into a container after boiling and cool for subsequent use;

[0038] S3), select a container, dilute the bagasse with water, add Saccharomyces cerevisiae, and ferment for more than 48 hours. After the alcohol content of the cane juice reaches 5-6°, put it in a heating tank and heat it to 65°C, and filter out the bagasse , to obtain a filtrate; the weight ratio of bagasse to Saccharomyces cerevisiae is 2000:1. Saccharomyces cerevisiae is prepared by mixing Saccharomyces cerevisiae from small koji wine, Saccharomyces cerevisiae from large koji wine and Saccharomyces cerevisiae from sugarcane alcohol, and the mass ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com