Cleasable cell microcapsules and its preparation method and cell culture method

A technology for lysing cells and cell culture, which is applied in the field of lysable cell microcapsules and its preparation, and cell culture such as cell adherence culture, which can solve the problems of cell loading time limit and other problems, and achieve an environment that ensures accurate development and good metabolism. good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In an exemplary microcapsule preparation method, it includes the following steps:

[0034] Prepare sodium alginate, calcium chloride, polylysine;

[0035] After dissolving sodium alginate in double distilled water, make sodium alginate solution, filter and sterilize for later use;

[0036] Calcium chloride is dissolved in double distilled water to make a calcium chloride solution, which is filtered and sterilized for subsequent use;

[0037] Dissolve polylysine in double distilled water to make polylysine solution, filter and sterilize for later use;

[0038] Add the cells to be cultured into the sodium alginate solution to make a mixed suspension of sodium alginate cells;

[0039] Adjust the density of cells and the concentration of sodium alginate in the mixed suspension;

[0040] The mixed suspension of sodium alginate cells was added to the calcium chloride solution and allowed to stand for 10 minutes to form stable calcium alginate beads.

[0041] Add calcium a...

Embodiment 1

[0051] 1. After dissolving sodium alginate in water, filter it with a 0.22 micron filter. Calcium chloride is formulated into a calcium chloride solution according to a mass volume ratio of 1.1%, and filtered with a 0.22 micron filter. The polylysine was formulated into a 0.05% concentration solution and filtered with a 0.22 micron filter.

[0052] 2. The cells were added to the sodium alginate solution to prepare a sodium alginate cell mixture, and the final concentration of sodium alginate in the sodium alginate cell mixture was controlled to be 1% (w / v).

[0053] 3. The sodium alginate cell suspension was dripped into the calcium chloride solution through a syringe using oxygen blowing pressure to condense into calcium alginate beads, let stand for 10 minutes, and then rinsed 3 times with sterile normal saline.

[0054] 4. Add calcium alginate beads into the polylysine solution, let it stand for 10 minutes, and then rinse it with sterile saline for several times.

[0055]...

Embodiment 2

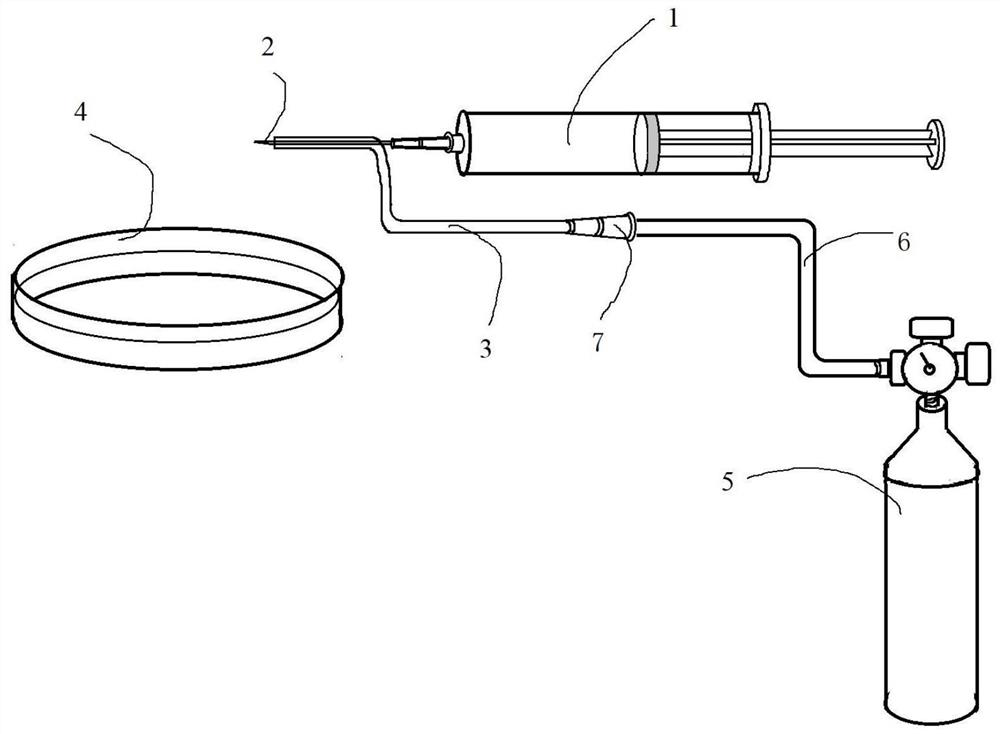

[0057] This example is used to illustrate the process of adding sodium alginate dropwise using a microcapsule generating device.

[0058] The microcapsule generating device in this embodiment includes a syringe (1), a syringe needle (2), a sterile plastic blown pressurized tube (3), a connector (7) and an oxygen pipeline (6).

[0059] When in use, suck the cell sodium alginate solution with a syringe (1). Insert the syringe needle (2) from the side wall of the sterile plastic blown pressurized tube (3). The syringe needle (2) should protrude beyond the end of the sterile plastic blown pressurized tube (3). Connect the sterile plastic blown pressurized tube connector (7) to the oxygen line (6). The oxygen valve is opened, and the pressure is adjusted to 5pa, and it can be seen that eddy surges are generated in the calcium chloride solution in the petri dish (4). Pressurize and push the syringe (7) at a constant speed. When made, the resulting suspension should be dripped on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com