Synchronous suspension control method for horizontal-axis wind-power cabin

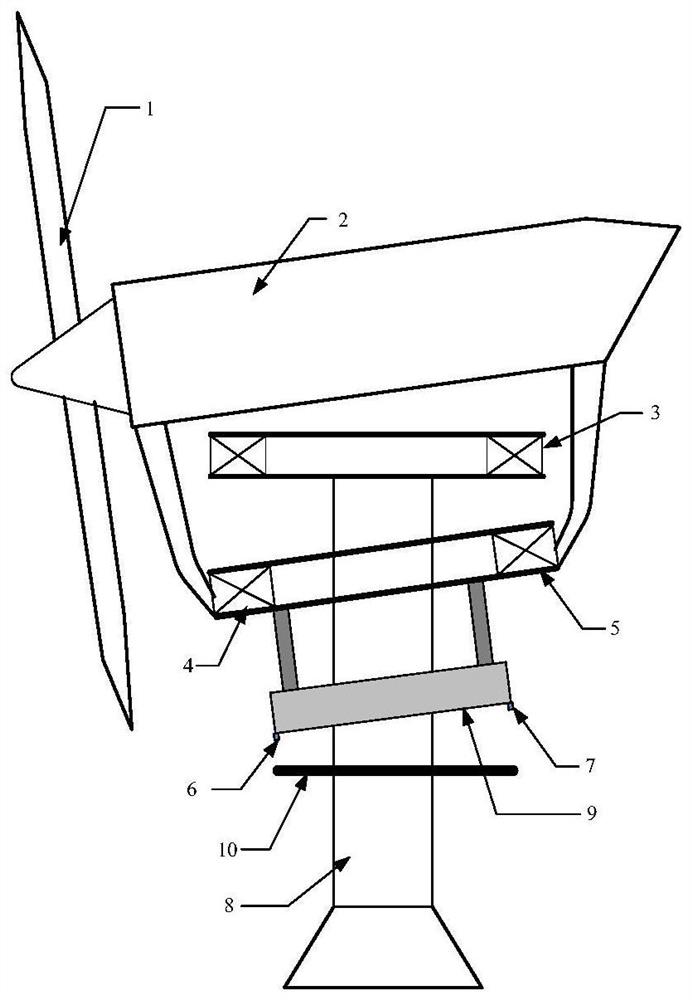

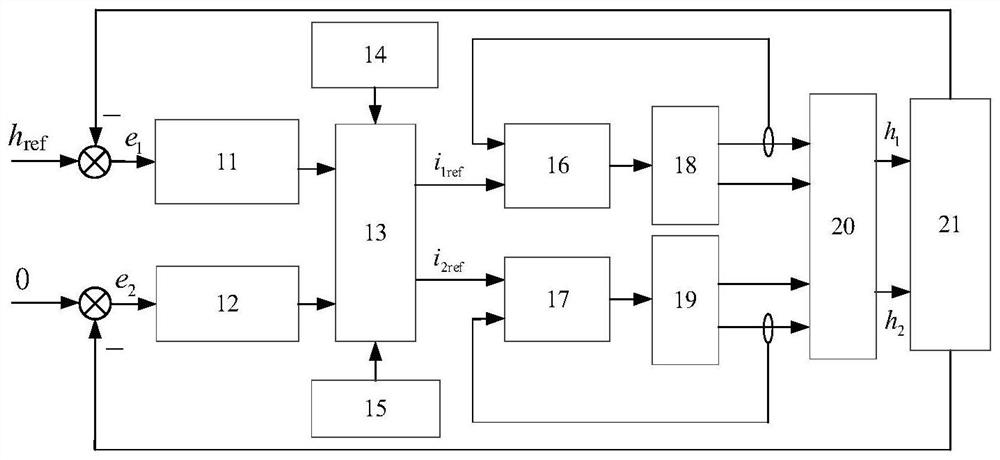

A technology of suspension control and synchronous controller, which is applied in the control of wind turbines, wind turbines, and engine control, etc., can solve the problems of large yaw power consumption of wind turbines, poor wind accuracy, and affecting the suspension stability of wind turbine cabins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

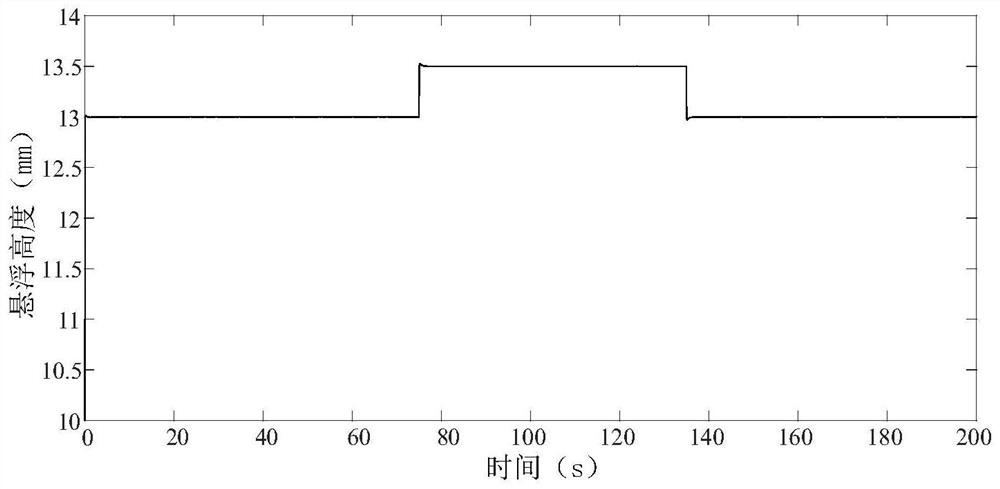

[0063] Example 1: A variable air gap tracking simulation experiment, such as image 3 and Figure 4 As shown, the cabin starts to float at t=0s, and the initial suspension height is 10mm. Among them, the suspension height of the cabin from 0 to 75s is set as 13mm, and the suspension height at t=75s to 145s is 13.5mm, and t=145s to 200s suspension The height reference height is 13mm, and the performance is compared and analyzed with the traditional two-point independent control state feedback controller (hereinafter referred to as the traditional controller). The suspension performance is shown in Table 3, the starting time is 0.5s, and the reference change transition time is 1.0s , the overshoot is 0.025mm, and the steady-state error is 0.001mm, which is far superior to the suspension performance of the traditional controller, which verifies that the present invention has strong air gap tracking capability and steady-state performance.

[0064] Table 3 Comparison of variable ...

example 2

[0068] Example two unilateral interference simulation experiment, such as Figure 5 and Figure 6 As shown, the synchronization performance of the suspension control on both sides of the nacelle is analyzed. Set the reference value of the initial height of the nacelle to 13mm, apply a suspended weight of 22.5kg to the tail side of the system from 80s to 140s, and create a unilateral downforce of 225N for the system, simulating the lateral force generated by the external wind on the nacelle. Carry out the performance contrast of the state feedback controller (hereinafter referred to as the traditional controller) of the present invention and traditional two-point independent control respectively, as shown in table 4, the present invention respectively falls on the maximum height drop, suspension height drop return time, suspension height maximum. Appreciation and suspension height return time are obviously better than those without synchronous controller (1.48mm, 0.5s, 1.55mm,...

example 3

[0069] Examples of three-axis interference simulation experiments, such as Figure 7 and Figure 8 As shown, the reference value of the initial suspension height of the nacelle is set to 13mm, and a 40kg heavy object is applied to the suspended nacelle for 80s to 140s to create a 400N axial downward pressure on the system to simulate the downforce generated by the external wind on the nacelle. Carry out the performance comparison of the state feedback controller (hereinafter referred to as traditional controller) of the present invention and traditional two-point independent control respectively, contrast result is as shown in table 5, no matter be at the maximum drop value of suspension height, drop return time, suspension height maximum In terms of rising value and rising return time, the control effect of the present invention is obviously better than that of the traditional controller (0.42mm, 1.4s, 0.5mm, 1.4s).

[0070] Table 5 Axial interference force application perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com