Magnetic circuit designing method capable of adjusting magnetic interface form of magnetic conductive column Hall thruster

A technology of Hall thruster and magnetic circuit design, applied in thrust reversers, mechanical equipment, machines/engines, etc., can solve the problems of low electron utilization efficiency, high electron loss, low thruster discharge efficiency, etc. Utilize efficiency, reduce electron loss, and realize the effect of high-efficiency discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

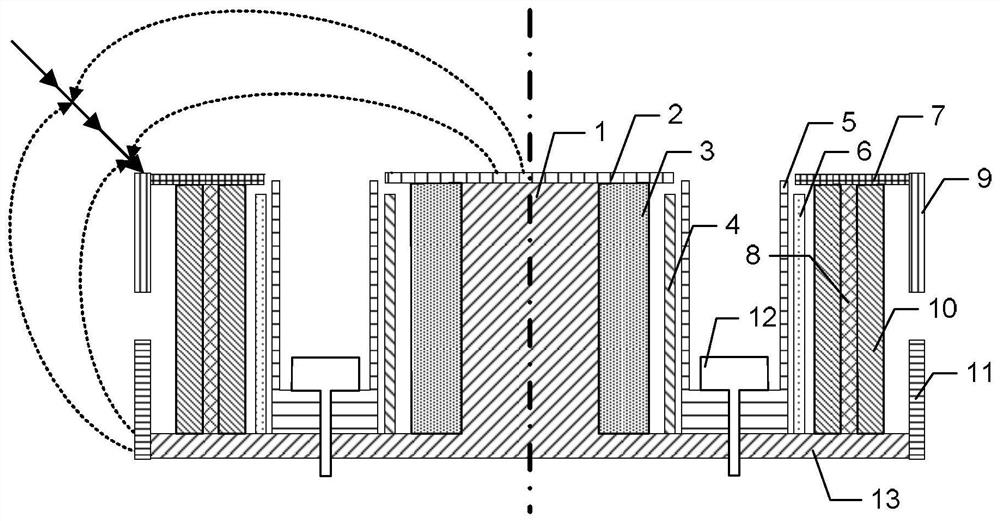

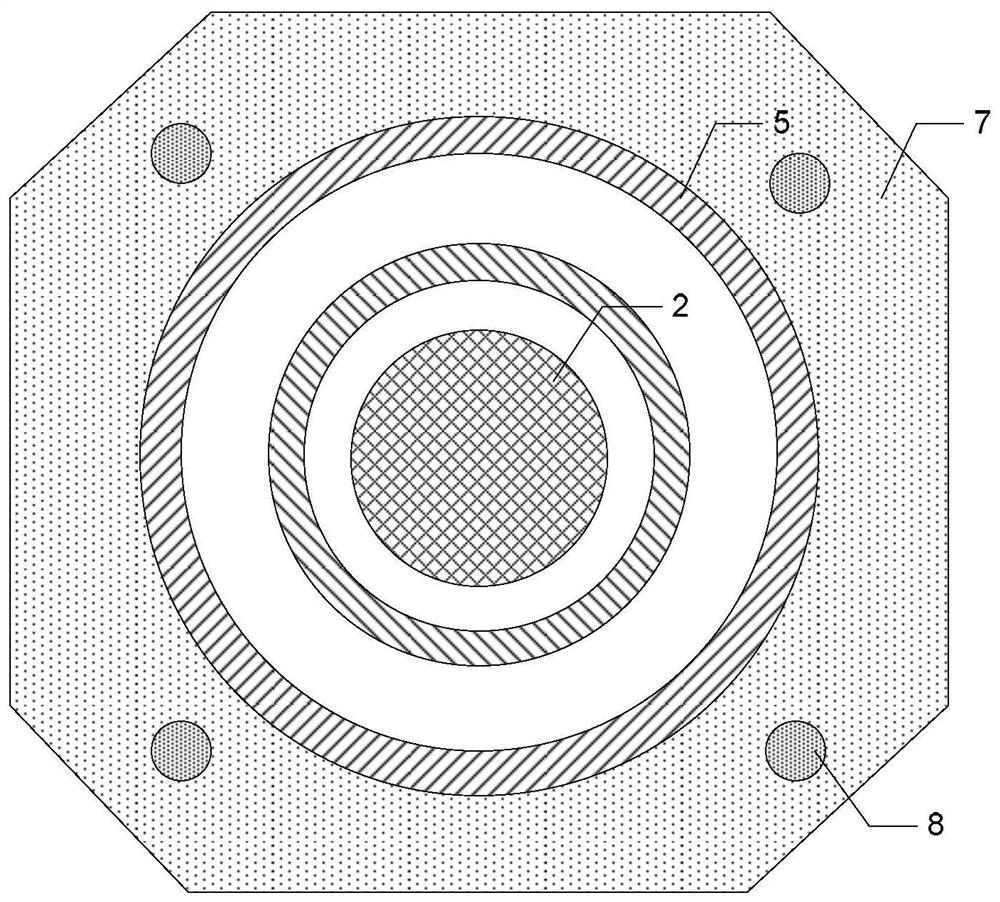

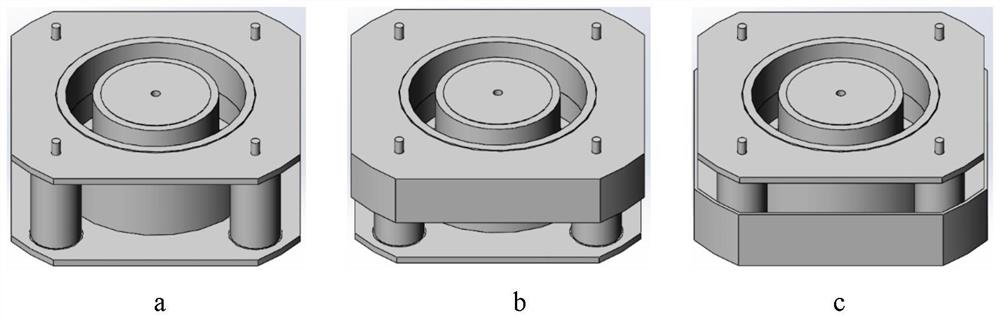

[0028] Specific implementation mode one: combine Figure 1 to Figure 9 Describe this embodiment, a magnetic circuit design method for adjusting the magnetic interface shape of the magnetic post Hall thruster described in this embodiment, the magnetic circuit structure design method is realized based on the magnetic post Hall thruster;

[0029] The magnetic column Hall thruster includes an inner iron core 1, an inner magnetic pole 2, an inner excitation coil 3, an inner magnetic screen 4, an integrated ceramic discharge channel 5, an outer magnetic screen 6, an outer magnetic pole 7, a magnetic column 8, External excitation coil 10, anode 12 and bottom plate 13;

[0030] The inner iron core 1 is cylindrical, and the inner iron core 1 is vertically fixed on the bottom plate 13, and the inner iron core 1 and the bottom plate 13 are integrally structured;

[0031] The inner magnetic pole 2 is arranged on the top of the inner iron core 1, the inner excitation coil 3 is wound on th...

specific Embodiment approach 2

[0046] Specific embodiment 2: This embodiment is to further limit the magnetic circuit design method for adjusting the magnetic interface form of the magnetic column Hall thruster described in the specific embodiment 1. In this embodiment, the inner iron core 1, The inner magnetic pole 2, the inner magnetic shield 4, the outer magnetic shield 6, the outer magnetic pole 7, the magnetic pole 8, the upper shell 9 and the lower shell 11 are respectively made of DT4C pure iron.

[0047] In this embodiment, the above-mentioned settings ensure the magnetic permeability and high temperature resistance of the structure, while ensuring the strength of the structure, effectively ensuring the stability of magnetic permeability, and improving the ability to resist high temperature and particle bombardment.

specific Embodiment approach 3

[0048] Specific embodiment three: This embodiment is to further limit the magnetic circuit design method for adjusting the magnetic interface shape of the magnetic column Hall thruster described in the specific embodiment one. In this embodiment, the integrated ceramic discharge channel 5 Made from a mixture of boron nitride and silicon dioxide.

[0049] In this embodiment, the hardness and compactness of the ceramic tube are ensured through the above configuration, and the ability to resist high temperature and particle bombardment is effectively improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com