Electrode structure for generating pulse point light source

A technology of electrode structure and point light source, which is applied to X-ray tube electrodes, X-ray tube structure circuit components, circuits, etc., can solve problems such as low experimental efficiency, unstable position of X-ray light emitting point, and off-center point of crossing point, etc. , to achieve the effect of improving experimental efficiency, easy and accurate load problems, and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

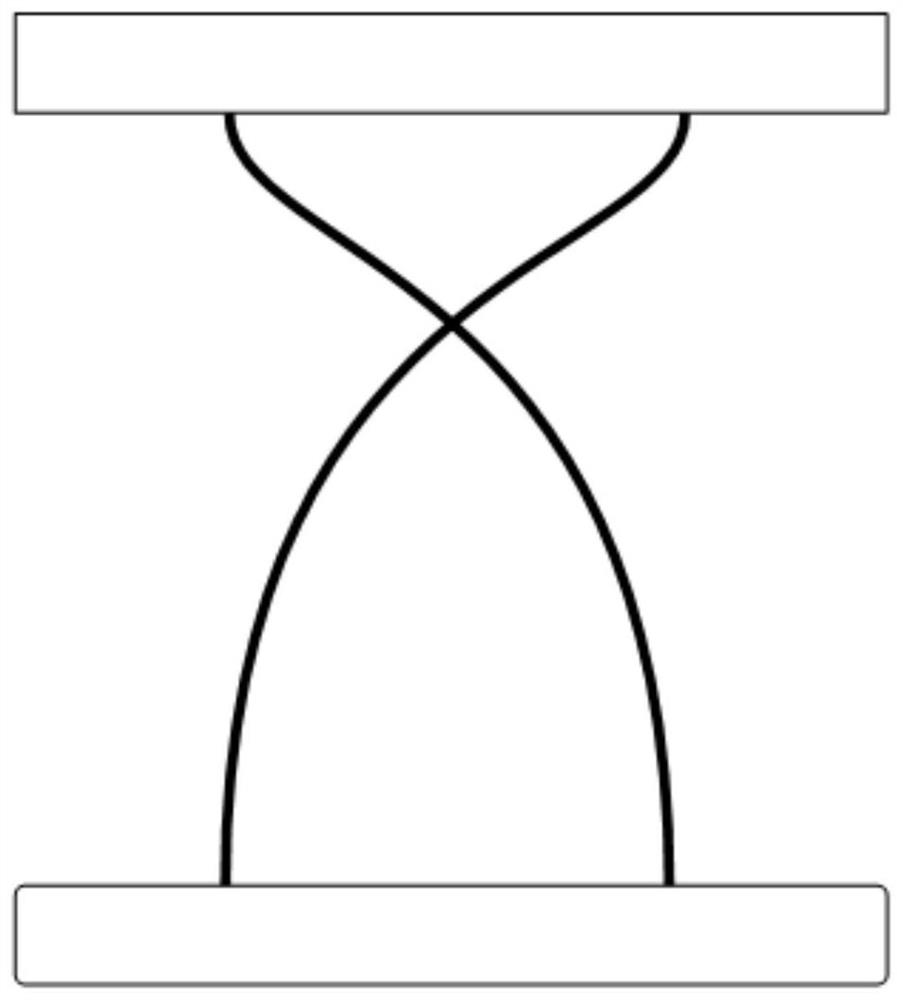

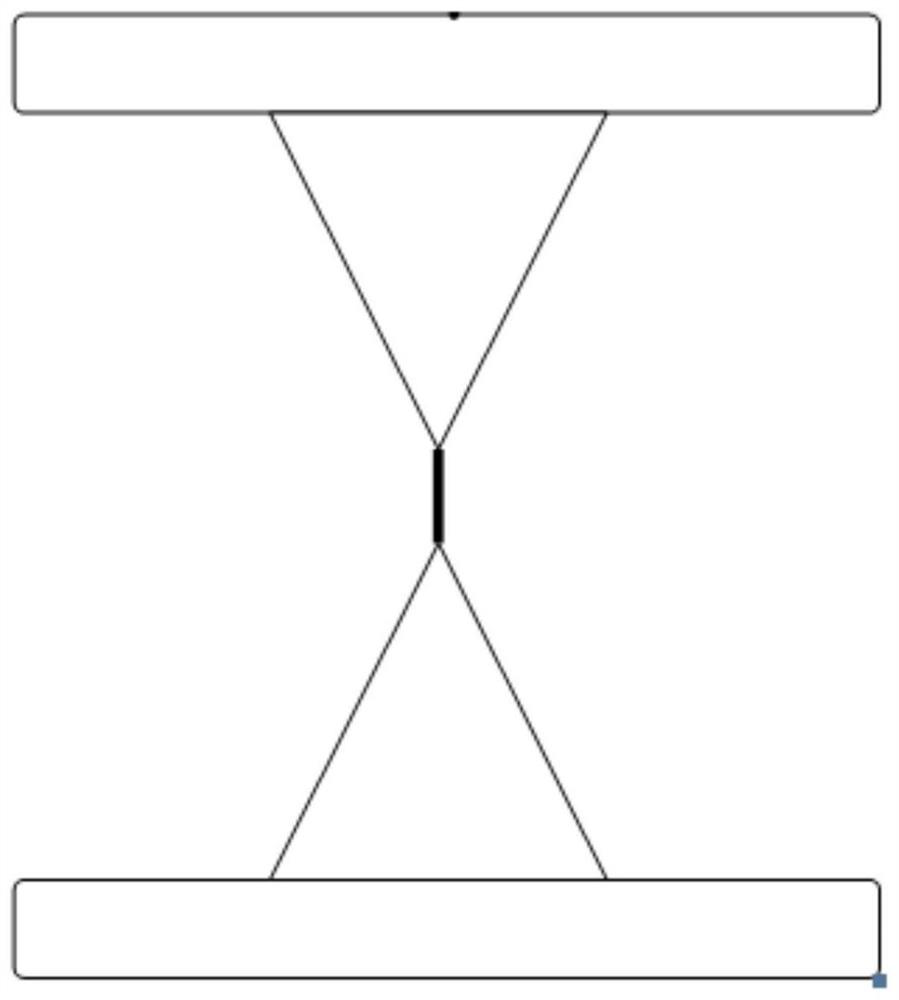

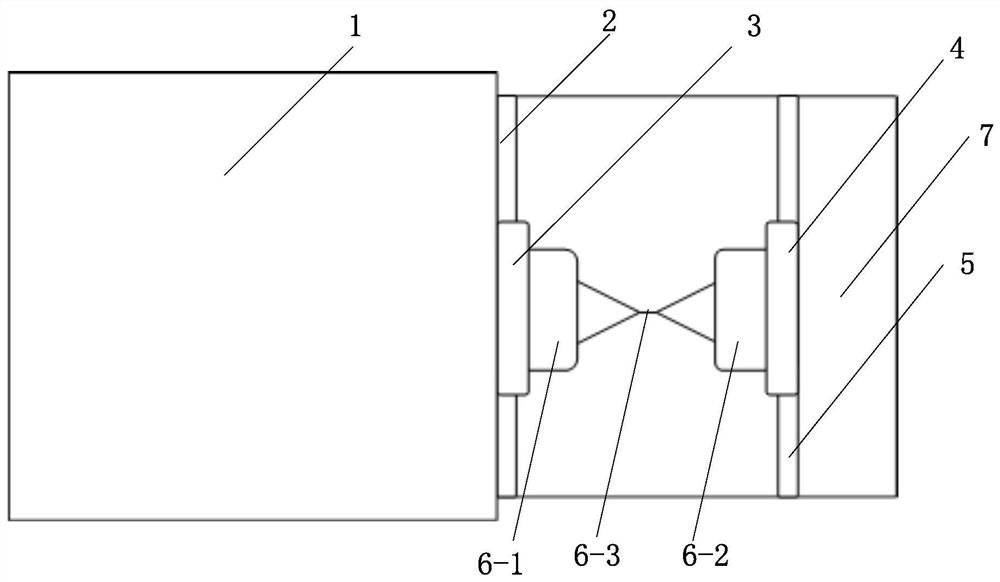

[0025] according to Figure 1a As shown in the previous conventional experiments, it was found that under the action of strong current pulse waves, the intersecting metal wires will first explode at the intersection point, and the gasified metal wires will instantly condense into high-temperature and high-density plasma under the action of magnetic field pressure. , radiate pulsed X-rays, the whole physical process occurs within the distance of 1mm up and down at the fork point, according to this phenomenon, a conical electrode loading structure is developed. It adopts conical electrodes as cathode and anode. The cone tips of conical cathode and anode need to be aligned and in a horizontal plane. Only one metal wire is installed between the conical cathode and anode to form the load. It can generate stable under the driving of strong current pulse. The pulsed point light source is quick and easy to install, and can completely replace the original cross wire load structure. In ...

Embodiment 2

[0027] Embodiment 2: wire changing operation

[0028] 1. Disassemble the return electrode;

[0029] 2. Disassemble the cathode holder;

[0030] 3. After the cathode is installed on the wire, the cathode holder is installed into the output electrode screw hole;

[0031] 4 After the cathode outlet wire is loaded into the anode wire hole, the return electrode is fixedly installed with the metal flange.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com