A kind of preparation method of low magnetic hysteresis tunnel junction magnetic sensor

A magnetic tunnel junction and tunnel junction technology, applied in the field of magnetic sensors, can solve the problems such as the difficulty of reducing the magnetic hysteresis of the sensitive body, and achieve the effects of eliminating the formation of short-circuit channels, improving the sensitivity, and improving the success rate of preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

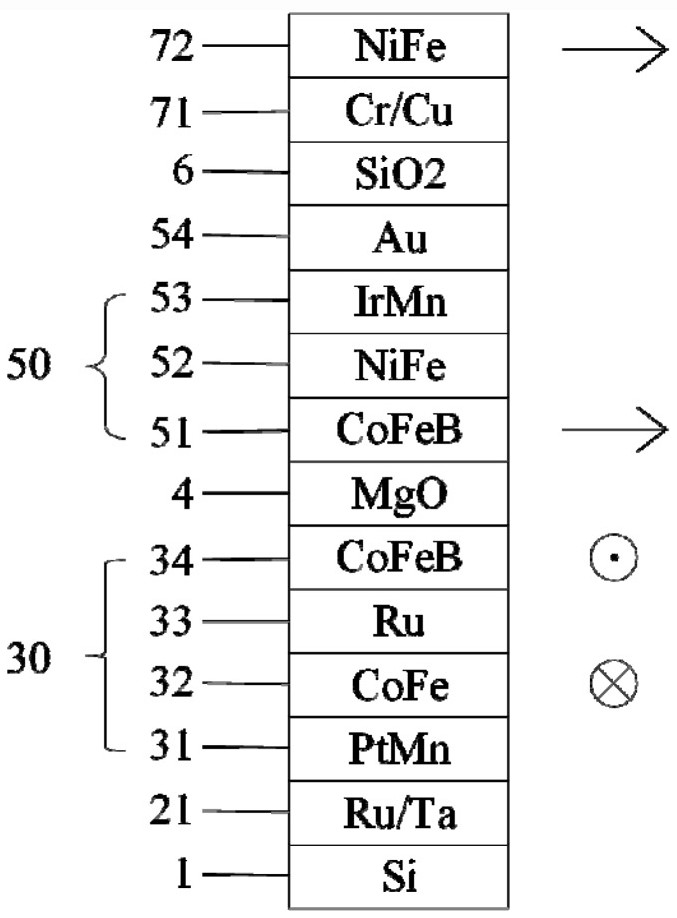

[0042] Using silicon dioxide as the substrate, through the background vacuum of 10 -6 The magnetron sputtering method of Pa, prepared such as figure 1 The low hysteresis tunnel junction magnetic susceptor shown, from bottom to top, sequentially includes a substrate 1, a buffer layer 21 (seed layer), a bottom electrode layer 30, a tunneling barrier layer 4, a first top electrode layer 50, and a second top electrode layer 50. The magnetization directions of the electrode layer 54 , the insulating layer 6 , the plating seed layer 71 and the plating layer 72 , and the bottom electrode layer 30 are perpendicular to the magnetization direction of the first top electrode layer 50 and the second top electrode layer 54 (or the plating layer 72 ). in:

[0043] The buffer layer 21 is a seed layer separated from each other by Ta / Ru;

[0044] The bottom electrode layer 30 includes, from bottom to top, a PtMn antiferromagnetic layer 31 with a thickness of 20 nm, a CoFe ferromagnetic layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com