Composite long-fiber nonwoven fabric using eccentric sheath-core composite fibers on at least one side

A long-fiber non-woven fabric and composite fiber technology, applied in the direction of conjugated synthetic polymer artificial filament, application, non-woven fabric, etc., can solve the problems of inappropriate sheet formation, difficulty in obtaining bulkiness, high friction, etc. Achieve excellent processing suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

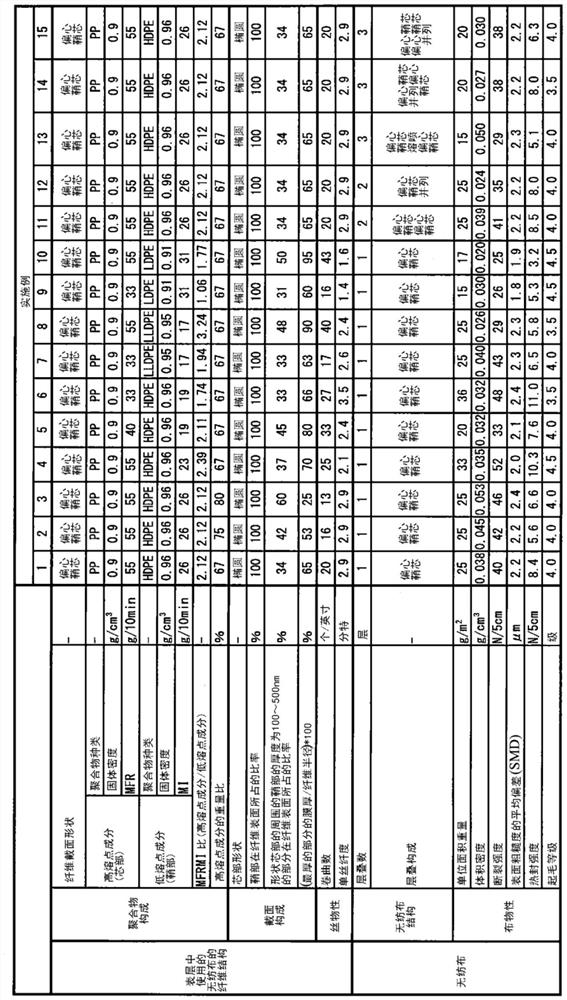

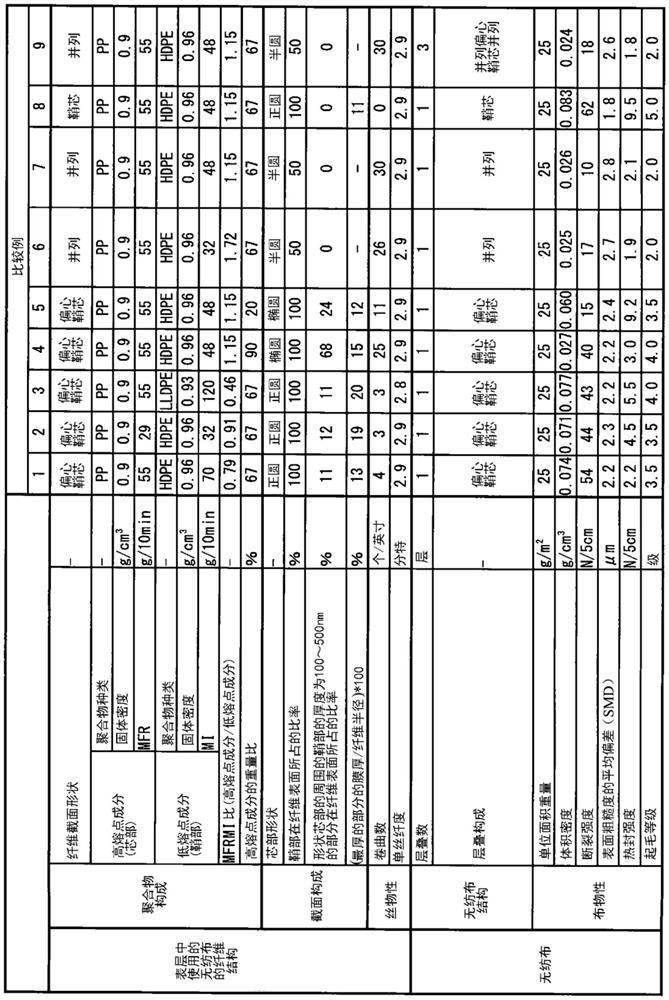

Embodiment 1

[0095] A polypropylene (hereinafter also referred to as PP) resin having an MFR of 55 g / 10 minutes (measured at a temperature of 230° C. and a load of 2.16 kg in accordance with JIS-K7210) was used as a high melting point component, and MI was 26 g / 10 minutes (according to JIS). -K7210, measured at a temperature of 190°C and a load of 2.16kg) high-density polyethylene (hereinafter also referred to as HDPE) resin as a low-melting component, the ratio of the high-melting component to the low-melting component is 67 / 33 by spunbonding The fibers were extruded at a spinning temperature of 230° C. and captured on a moving collection surface to produce an eccentric sheath-core type long-fiber nonwoven web with an average monofilament fineness of 2.9 dtex.

[0096] Next, about the obtained web, the fibers were bonded to each other by hot air with a hot air temperature of 140° C. and a hot air speed of 1.0 m / sec to obtain a basis weight of 25 g / m. 2 And the number of crimps 20 / inch c...

Embodiment 2

[0098] A composite long-fiber nonwoven fabric was obtained in the same manner as in Example 1, except that the ratio of the high melting point component and the low melting point component was 75 / 25.

Embodiment 3

[0100] A composite long-fiber nonwoven fabric was obtained in the same manner as in Example 1, except that the ratio of the high melting point component and the low melting point component was 80 / 20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com