Closed stock bin moving in wheel type

A wheeled and silo technology, applied in the field of closed silos, can solve the problems of high construction costs, unaffordable enterprises, waste of resources, etc., and achieve the effect of good effect, low cost, flexible and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

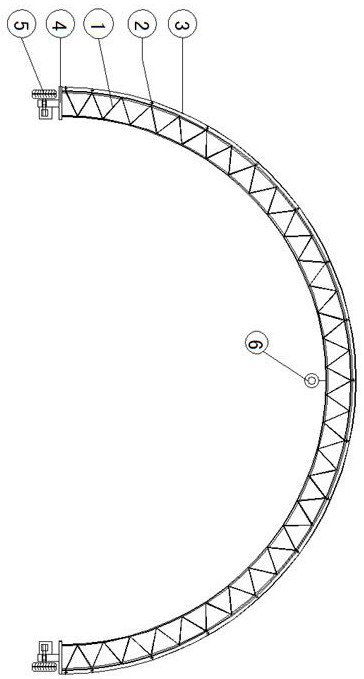

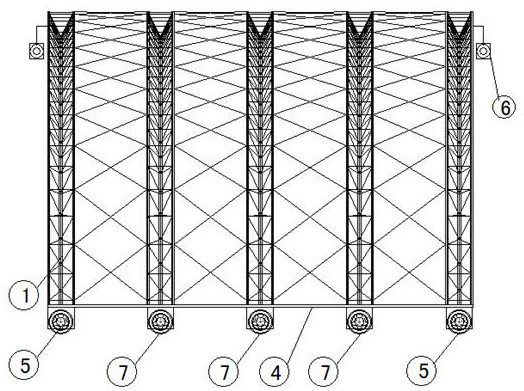

[0022] Embodiment: A wheeled mobile closed silo is characterized by a steel structure 1, connectors 2, roof panels 3, suspensions 4, wheeled walking mechanism, and an infrared shielding system 6.

[0023] The outer surface of the steel structure 1 is equidistantly welded to the connecting piece 2, and the roof panel 3 is installed on the connecting piece 2 with self-tapping screws. The barrier system 6 is installed on top of both ends of the steel structure 1.

[0024] The steel structure is a grid or pipe truss structure to form a hemispherical shape, and the grid members are connected with each other by bolts and balls. The tube truss structure is adopted, and the steel material is used for splicing.

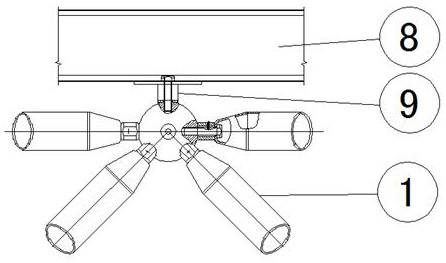

[0025] The connector 2 is composed of a bracket 9 and a purlin 8, the bracket 9 is equidistantly installed on the outer surface of the steel structure 1, the purlin 8 is C-shaped steel, and the purlin 8 is installed on the bracket 9. The connectors provide mounting support f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com