Graphite slag light partition board and preparation method thereof

A lightweight partition board and graphite slag technology, applied to walls, building components, sustainable waste treatment, etc., can solve the problems of occupying land resources around graphite factories, urban and rural environmental damage, etc., to achieve lightweight installation and protect the living environment , the effect of reducing the heat of hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

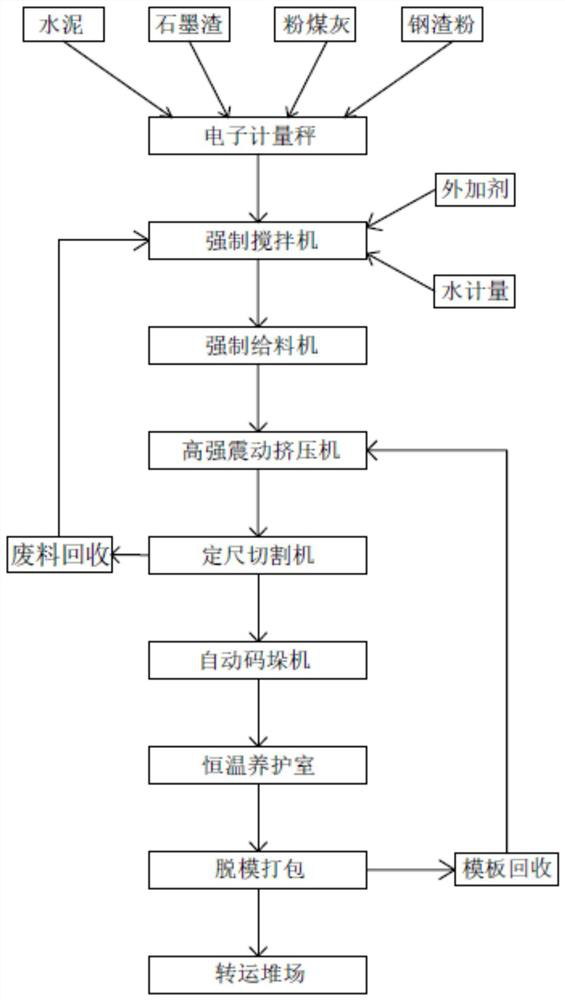

[0025] A graphite slag lightweight partition board and a preparation method thereof. The raw materials for preparing the graphite slag lightweight partition board include dry material and water, and the dry material is prepared from the following components in parts by mass: 50 parts of graphite tailings, 20 parts of steel slag powder, 20 parts of cement, 15 parts of fly ash, 0.02 parts of drag reducer, and 0.08 parts of water resistance enhancer, wherein the amount of water added is based on the total weight of dry materials , the water-solid ratio between the water and the dry material is 10wt%; the preparation method of the graphite slag lightweight partition wall board comprises the following preparation steps:

[0026] Step 1, after measuring the graphite tailings, steel slag powder, cement, fly ash, drag reducer, and water-resistant enhancer through an electronic weighing scale, fully stir with water to obtain a semi-dry material;

[0027] Step 2: Send the semi-dry mater...

Embodiment 2

[0039] A graphite slag lightweight partition board and a preparation method thereof. The raw materials for preparing the graphite slag lightweight partition board include dry material and water, and the dry material is prepared from the following components in parts by mass: 60 parts of graphite tailings, 22 parts of steel slag powder, 25 parts of cement, 20 parts of fly ash, 0.035 parts of drag reducer, and 0.09 parts of water resistance enhancer, wherein the amount of water added is based on the total weight of dry materials , the water-solid ratio between the water and the dry material is 12wt%; the preparation method of the graphite slag lightweight partition wall board comprises the following preparation steps:

[0040] Step 1, after measuring the graphite tailings, steel slag powder, cement, fly ash, drag reducer, and water-resistant enhancer through an electronic weighing scale, fully stir with water to obtain a semi-dry material;

[0041] Step 2: Send the semi-dry mate...

Embodiment 3

[0053] A graphite slag lightweight partition board and a preparation method thereof. The raw materials for preparing the graphite slag lightweight partition board include dry material and water, and the dry material is prepared from the following components in parts by mass: 70 parts of graphite tailings, 25 parts of steel slag powder, 30 parts of cement, 25 parts of fly ash, 0.05 parts of drag reducer, 0.1 part of water resistance enhancer, wherein the amount of water added is based on the total weight of dry materials , the water-solid ratio between the water and the dry material is 15wt%; the preparation method of the graphite slag lightweight partition wall board comprises the following preparation steps:

[0054] Step 1, after measuring the graphite tailings, steel slag powder, cement, fly ash, drag reducer, and water-resistant enhancer through an electronic weighing scale, fully stir with water to obtain a semi-dry material;

[0055] Step 2: Send the semi-dry material ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com