Polyisocyanate composition and preparation method and application thereof

A technology of polyisocyanate and diisocyanate, which is applied in the field of polyisocyanate composition of polyurethane paint and its preparation, can solve the problem that the color number of polyisocyanate composition is difficult to keep stable, and achieve excellent color number stability and good color number stability , high wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

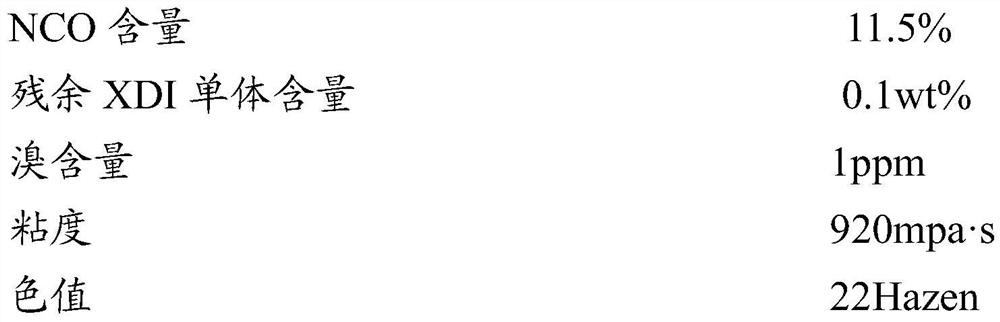

[0068] Under nitrogen protection, add 368.9 parts by weight of m-xylylene diisocyanate (XDI) into the reactor, heat and stir at 80°C, then add 52.6 parts by weight of trimethylolpropane dropwise into the reactor, dropwise After the completion, continue to stir and react at 80°C for 1 hour, and the obtained polyurethane prepolymer reaction solution enters the polyurethane prepolymer tank, and the above reaction solution has been mixed for 4 hours -1 The volume space velocity passes through the fixed bed of debromination agent A, and the reaction temperature is 70°C. Separation was then carried out using a thin-film distiller at a temperature of 145° C. and a pressure of 0.5 mbar. The separated prepolymer enters the dilution tank and dilutes with ethyl acetate to obtain the polyisocyanate composition of 75wt% solid content, and has the following parameters:

[0069]

[0070] Use this polyisocyanate composition to carry out the storage stability test at room temperature, and ...

Embodiment 2-8 and comparative example 1-3

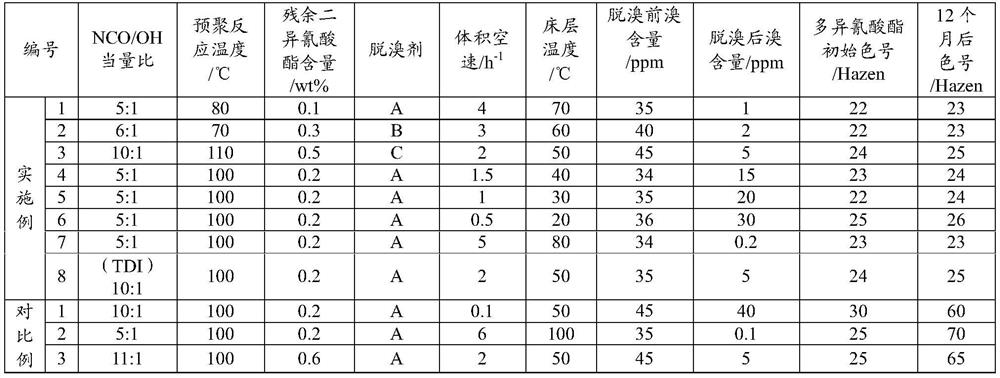

[0072] Samples with different indicators were obtained by changing the raw material ratio of the prepolymer reaction solution, preparation conditions, debromination conditions, and residual diisocyanate monomer content. The conditions and results are shown in Table 2 below.

[0073] Condition and result of table 2 embodiment 1-8 and comparative example 1-3

[0074]

[0075] Note: except that the diisocyanate is TDI in Example 8, the diisocyanate in the remaining examples is XDI.

[0076] It can be seen from the above examples and comparative examples that by controlling the content of bromine-containing compounds in the polyisocyanate composition to be 0.2-30ppm as bromine, based on the total weight of the polyisocyanate composition, the content of residual diisocyanate monomers is controlled to be 0.5wt%. Next, a polyisocyanate composition with stable color number can be obtained, which can keep the color number stable for at least 12 months.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com