Traction type slope cutting equipment

A kind of traction equipment and traction-type technology, which is applied in the direction of coastline protection, excavation, earth mover/shovel, etc., can solve the problems of large impact, low operation efficiency, high labor intensity, etc., and achieve long service life, stable travel, and improved The effect of construction flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

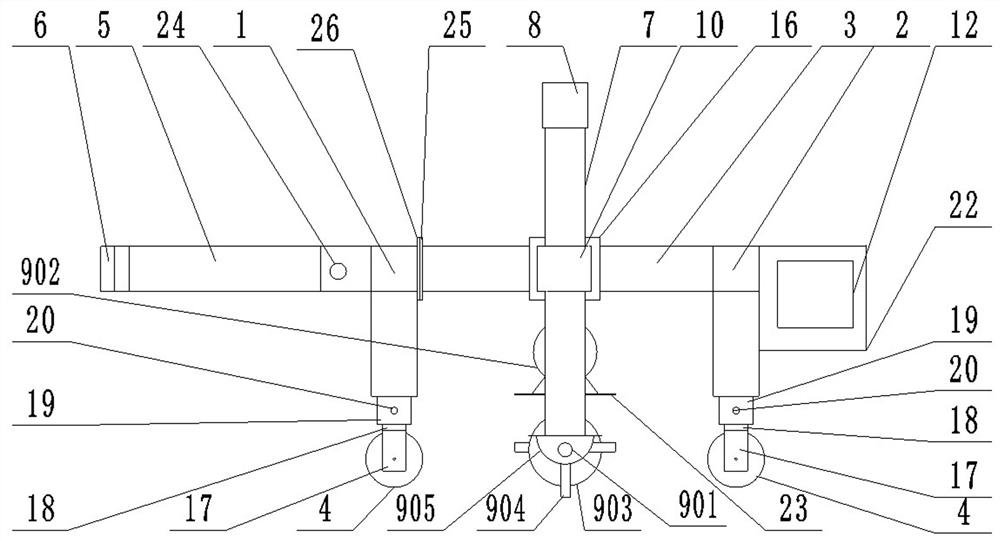

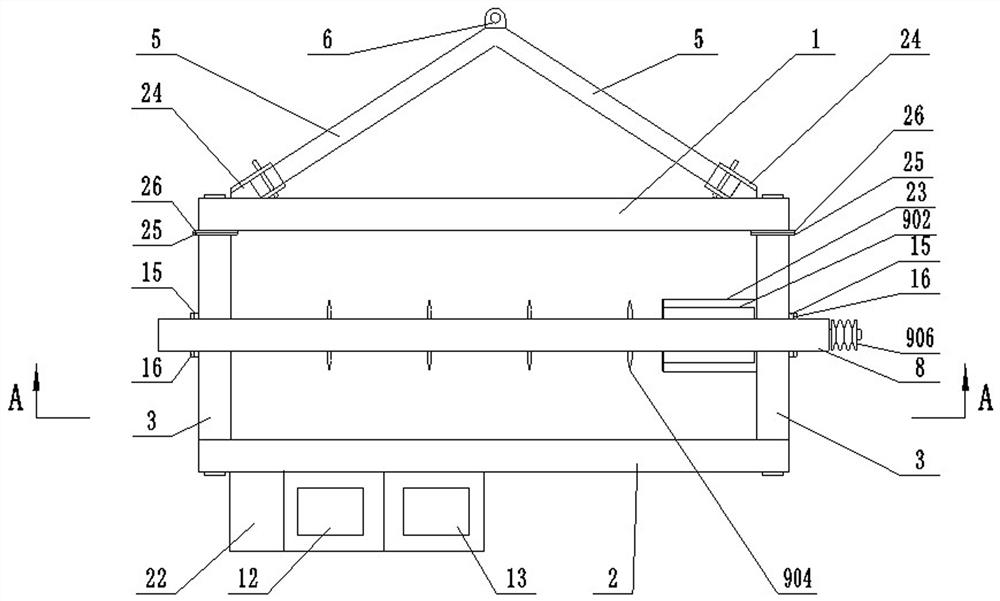

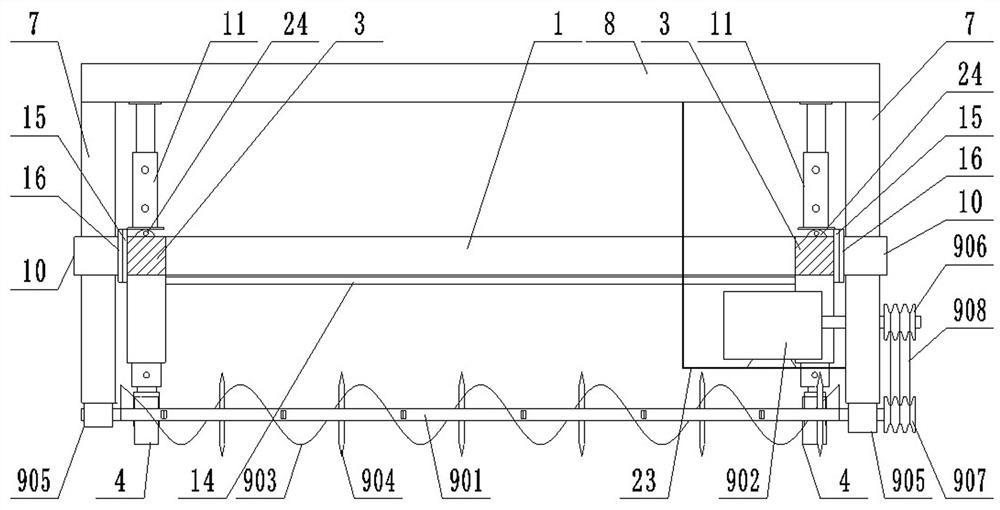

[0040]A traction type slope cutting equipment, including traction equipment, also includes a traveling mechanism hooked to the rear of the traction equipment, a slope cutting mechanism detachably connected to the rear of the running mechanism, and a lifting mechanism arranged between the running mechanism and the slope cutting mechanism. mechanism and a generator;

[0041] The walking mechanism includes a front door-shaped frame 1 and a rear door-shaped frame 2 distributed in parallel front and back, two first connecting beams 3 placed horizontally and parallel to the left and right are connected to the top of the two, and two universal glues are arranged on the bottom respectively. Wheel 4; the left end and the right end of the front surface of the front door frame 1 are respectively hinged with two drawbars 5 that can rotate up and down. Hanging ring 6, the traction equipment is connected with the running mechanism through the pulling ring 6;

[0042] The slope cutting mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com