Multi-dimensional combined adjustable CPC heat collection device

A heat collecting device and adjustable technology, applied in the field of solar energy utilization, can solve the problem that CPC heat collectors have no obvious advantages in performance and cost, limit the promotion, application and popularization of CPC heat collectors, lose the value and significance of CPC heat collectors, etc. problems, to achieve the effect of improving heat transfer speed and efficiency, reducing construction costs and operating costs, and increasing the range of receiving angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

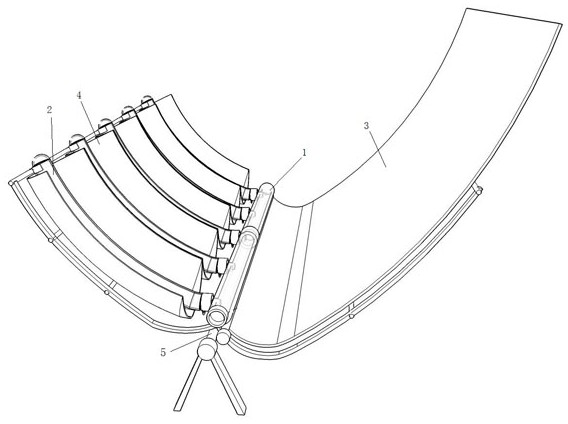

[0026] see figure 1 , using a multi-dimensional combined adjustable CPC heat collector, including a straight-through all-glass vacuum heat collector with a socket 1, a curved heat pipe vacuum heat collector 2, a primary semi-composite parabolic concentrating plate 3, and a secondary curved two-dimensional composite paraboloid Concentrating plate 4, double-stage adjustable angle support frame device 5; straight-through all-glass vacuum heat collecting tube 1 with jacks is placed horizontally, multiple curved heat pipe type vacuum heat collecting tubes 2 are placed side by side, and curved heat pipe type vacuum heat collecting tubes are placed side by side. The lower end of 2 is inserted into the straight-through all-glass vacuum heat collecting tube 1 with a socket, and the axis of the curved heat pipe type vacuum heat collecting tube 2 is bent upward; Curved two-dimensional compound parabolic concentrating plate 4, on the radial section of the curved heat pipe vacuum heat coll...

Embodiment 2

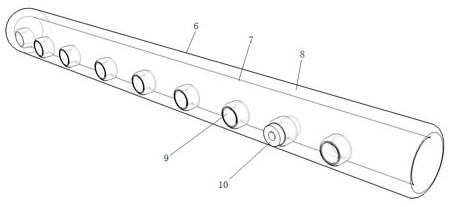

[0028] see figure 2 , as an improvement of the present invention, the curved heat pipe type vacuum heat collector tube 2 includes an outer glass tube 6, an inner glass tube 7, a vacuum layer 8 of an all-glass vacuum heat collector tube, a glass jack 9, and a rubber ring 10; The glass tube 6 is located outside the inner glass tube 7, and between the outer glass tube 6 and the inner glass tube 7 is the vacuum layer 8 of the all-glass vacuum heat collecting tube; the ends of the outer glass tube 6 and the inner glass tube 7 are connected by fusion sealing, The outside of the outer glass tube 6 communicates with the inside of the inner glass tube 7 through the glass socket 9, the glass socket 9 is embedded with a rubber ring 10, and the outer surface of the inner glass tube 7 is covered with a selective absorbing coating.

Embodiment 3

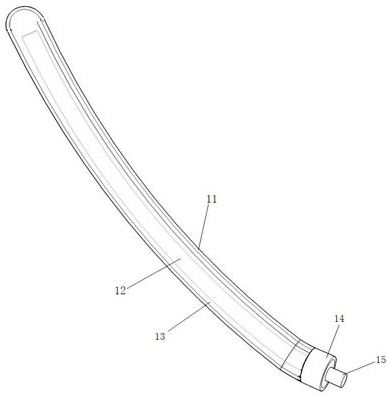

[0030] see image 3 , as an improvement of the present invention, the curved heat pipe type vacuum heat collecting tube 2 includes a curved glass tube 11, a heat pipe evaporation section 12, a heat pipe type vacuum heat collecting tube vacuum layer 13, a heat collecting tube end cover 14, and a heat pipe condensation section 15. The axis of the curved glass tube 11 is parallel to the axis of the heat pipe evaporation section 12 and is a section of a compound parabolic curve. The curved glass tube 11 is a single-layer glass sleeve. One end of the curved glass tube 11 is closed, and the other end is closed. Connected with the heat collecting tube end cover 14 to form a sealed space, the heat pipe evaporating section 12 and the heat pipe condensing section 15 are respectively located inside and outside the sealed space, the heat pipe evaporating section 12 and the heat pipe condensing section 15 are interconnected tubular structures, curved glass Between the tube 11 and the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com