Low-temperature drying method of camellia oleifera fruits

A drying method and camellia fruit technology, applied in the field of camellia storage, can solve the problems of oil coming from camellia seeds, uneven heating of camellia seeds, and high energy consumption, and achieve the effects of reducing mildew rate, shortening stacking processing time, and reducing stacking time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

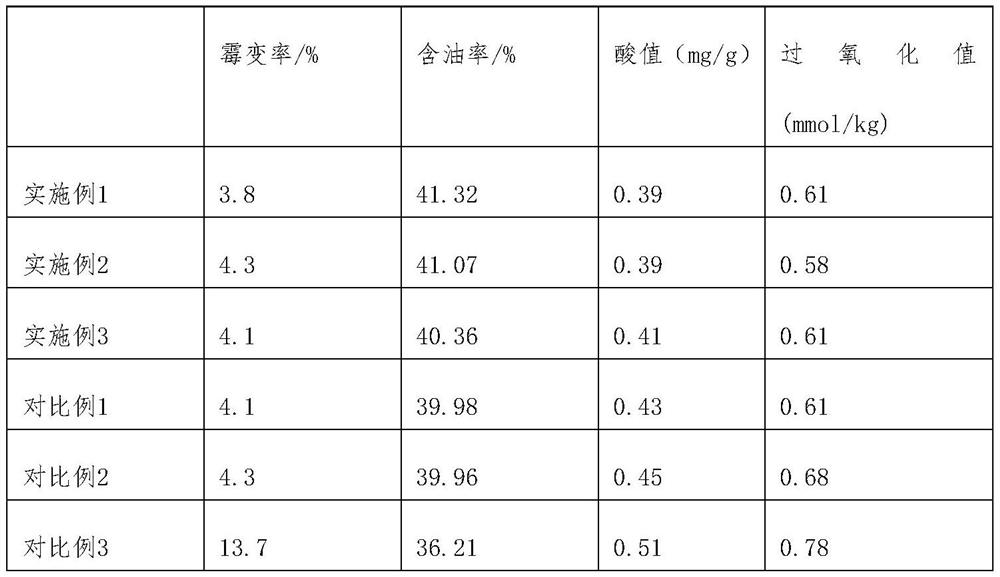

Examples

Embodiment 1

[0027] A low-temperature drying method for Camellia oleifera, comprising the following steps:

[0028] (1) Picking: 3-4 days before picking, spray the nutrient solution to the camellia oleifera fruit, and then pick the camellia oleifera fruit;

[0029] (6)(2) Stacking treatment: stack the camellia oleifera fruits picked indoors, add ethylene to the stacking room for ripening treatment, control the ethylene concentration and flow rate, and process for 24 hours; then use an air circulation machine to carry out air circulation treatment indoors , cycle treatment once every 20 minutes, air replacement and cycle treatment once every 6 hours, control the volume fraction of carbon dioxide in the room <15%, and treat for 24 hours; remove moldy and rotten fruits;

[0030] (3) Primary drying: place the processed Camellia oleifera fruit in the sun to dry in the sun until the shell cracks, put it into a peeling machine and take out the shell to obtain Camellia oleifera seeds;

[0031] (4...

Embodiment 2

[0038] A low-temperature drying method for Camellia oleifera, comprising the following steps:

[0039] (1) Picking: 3-4 days before picking, spray the nutrient solution to the camellia oleifera fruit, and then pick the camellia oleifera fruit;

[0040] (2) Stacking treatment: stack the camellia oleifera fruits picked by the phenomenon indoors, add ethylene to the stacking room for ripening treatment, control the ethylene concentration and flow rate, and process for 30h; Circulate once every 22 minutes, and replace the air once every 6 hours, control the volume fraction of carbon dioxide in the room < 15%, and treat for 30 hours;

[0041] (3) Primary drying: place the processed Camellia oleifera fruit in the sun to dry in the sun until the shell cracks, put it into a peeling machine and take out the shell to obtain Camellia oleifera seeds;

[0042] (4) Secondary drying: soak the camellia oleifera seeds in the pretreatment solution for 1-2 minutes, then dry the water and add it...

Embodiment 3

[0049] A low-temperature drying method for Camellia oleifera, comprising the following steps:

[0050] (1) Picking: 3-4 days before picking, spray the nutrient solution to the camellia oleifera fruit, and then pick the camellia oleifera fruit;

[0051] (2) Stacking treatment: stack the camellia oleifera fruit picked indoors, add ethylene to the stacking room for ripening treatment, control the concentration of ethylene and the flow rate, and process for 36 hours; Circulate treatment once every 25 minutes, replace the air every 6 hours, control the volume fraction of carbon dioxide in the room <15%, and treat for 36 hours; remove moldy and rotten fruits;

[0052] (3) Primary drying: place the processed Camellia oleifera fruit in the sun to dry in the sun until the shell cracks, put it into a peeling machine and take out the shell to obtain Camellia oleifera seeds;

[0053] (4) Secondary drying: put the camellia oleifera seeds into the pretreatment solution and soak for 1-2 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com