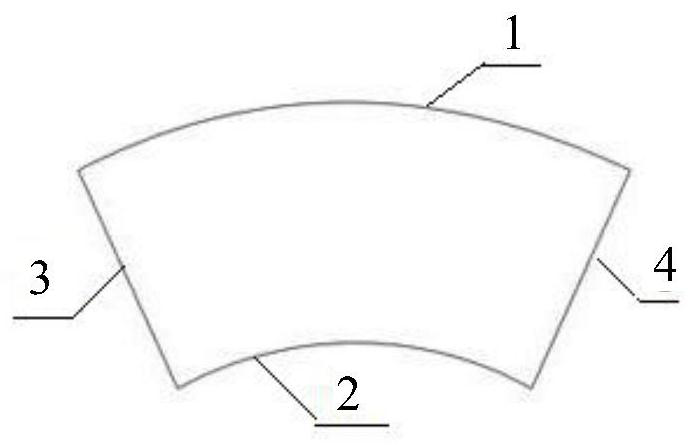

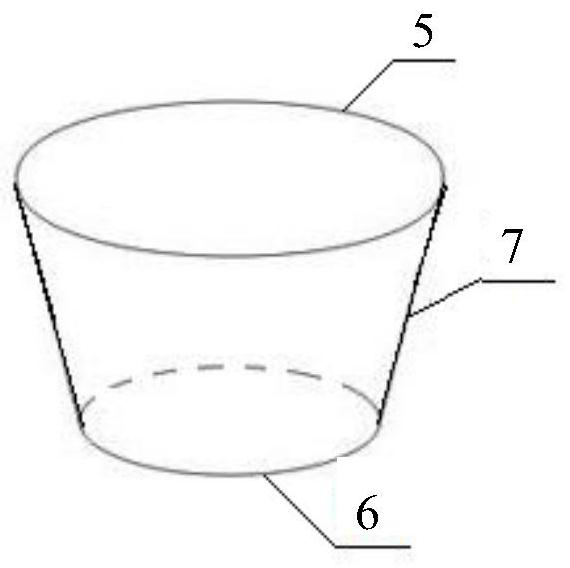

A kind of preparation method of conical side net for semi-submersible culture platform

A truncated, semi-submersible technology, applied in application, fish farming, melt spinning, etc., can solve the problem of no double dead knot type antifouling mesh, no antifouling composite material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the examples. However, the following examples should not be considered as limiting the scope of the present invention.

[0050] This embodiment takes the semi-submersible culture platform with the truncated truncated side net as an example with the specification as the upper bottom perimeter of 50 meters × 40 meters lower bottom perimeter × 6.2 meters of busbar side length, and the specific preparation method of the truncated circular side net to describe. At the same time, in this embodiment, the number of strands of the antifouling twisted yarn for processing the antifouling mesh is described by taking 105 strands as an example.

[0051] 1. Raw materials and equipment

[0052] The required raw materials and equipment in the method of the present invention are as follows: carbon fiber thread, ultra-high molecular weight polyethylene twisted line (abbreviated as UHMWPE twisted line), ultra-hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com