Novel self-leveling thermal insulation material and preparation method thereof

A thermal insulation material and self-leveling technology, which is applied in the field of building thermal insulation materials, can solve the problems of poor thermal insulation and sound insulation, poor construction performance, etc., achieve good environmental protection characteristics, good construction workability, and reduce plastic shrinkage cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

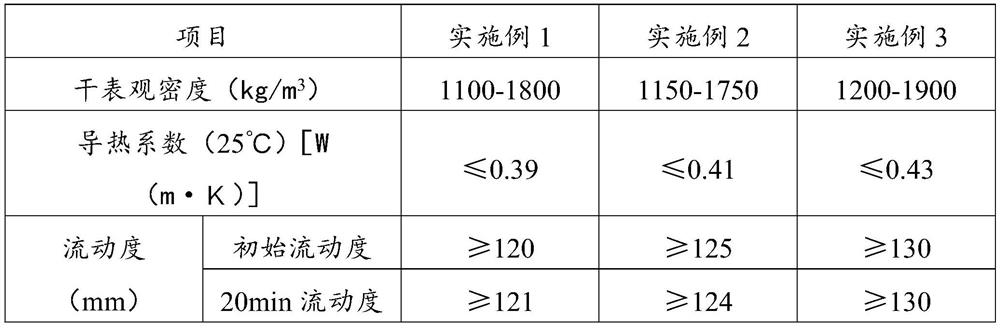

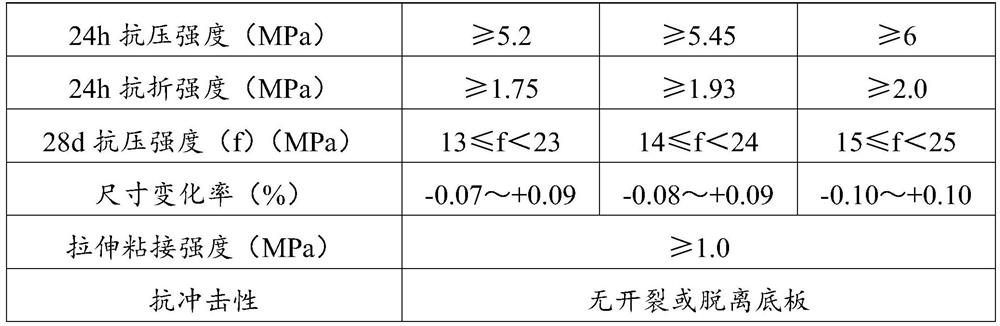

Embodiment 1

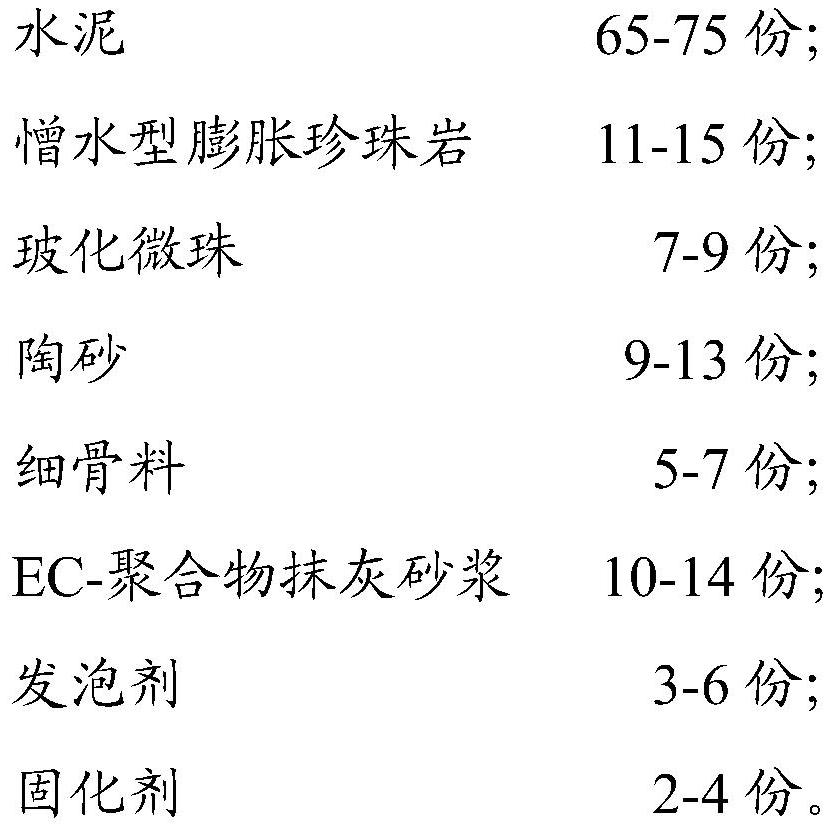

[0021] A new type of self-leveling thermal insulation material, its raw material components and the mass parts of each component are respectively:

[0022] 65 parts of cement, 11 parts of hydrophobic expanded perlite, 7 parts of vitrified microbeads, 9 parts of pottery sand, 5 parts of fine aggregate, 10 parts of EC-polymer plastering mortar, 3 parts of foaming agent, 2 parts of curing agent share.

[0023] The preparation method is as follows: by weight percentage, 65 parts of cement are weighed, water and cement are mixed according to the ratio of 0.2:1, and then 11 parts of hydrophobic expanded perlite, 7 parts of vitrified microbeads and 9 parts of pottery sand are mixed. Slowly add to the mixed cement slurry, and stir until uniform while adding; then add 5 parts of fine aggregate, 3 parts of foaming agent and 2 parts of curing agent, and stir until uniform while adding; finally, EC-polymer plastering mortar Slowly add 10 parts into water, stir until uniform while adding,...

Embodiment 2

[0025] A new type of self-leveling thermal insulation material, its raw material components and the mass parts of each component are respectively:

[0026] 70 parts of cement, 13 parts of hydrophobic expanded perlite, 8 parts of vitrified microbeads, 11 parts of pottery sand, 6 parts of fine aggregate; 12.5 parts of EC-polymer plastering mortar, 4.5 parts of foaming agent, 3 parts of curing agent share.

[0027] The preparation method is as follows: by weight percentage, 70 parts of cement are weighed, water and cement are mixed according to the ratio of 0.2:1, and then 13 parts of hydrophobic expanded perlite, 8 parts of vitrified microbeads, and 11 parts of pottery sand are mixed. Slowly add to the mixed cement slurry, and stir until uniform while adding; then add 6 parts of fine aggregate, 4.5 parts of foaming agent and 3 parts of curing agent, and stir until uniform while adding; finally, EC-polymer plastering mortar 12.5 Slowly add water, stir until uniform while adding,...

Embodiment 3

[0029] A new type of self-leveling thermal insulation material, its raw material components and the mass parts of each component are respectively:

[0030] 75 parts of cement, 15 parts of hydrophobic expanded perlite, 9 parts of vitrified microbeads, 13 parts of ceramic sand, 7 parts of fine aggregate, 14 parts of EC-polymer plastering mortar, 6 parts of foaming agent, 4 parts of curing agent share.

[0031] The preparation method is as follows: by weight percentage, 75 parts of cement are weighed, water and cement are mixed according to the ratio of 0.2:1, and then 15 parts of hydrophobic expanded perlite, 9 parts of vitrified microbeads, and 13 parts of pottery sand are mixed. Slowly add to the mixed cement slurry, and stir until uniform while adding; then add 7 parts of fine aggregate, 6 parts of foaming agent and 4 parts of curing agent, and stir until uniform while adding; finally, EC-polymer plastering mortar 14 Slowly add water, stir until uniform while adding, let sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com