A kind of directly cutting high-strength and tough hot-rolled round steel and its preparation method

A round steel, direct technology, applied in the direction of heat treatment equipment, manufacturing tools, heat treatment furnace, etc., can solve the problems of high material cost and low production efficiency, achieve the effect of improving production rhythm, reducing waiting time and promoting refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

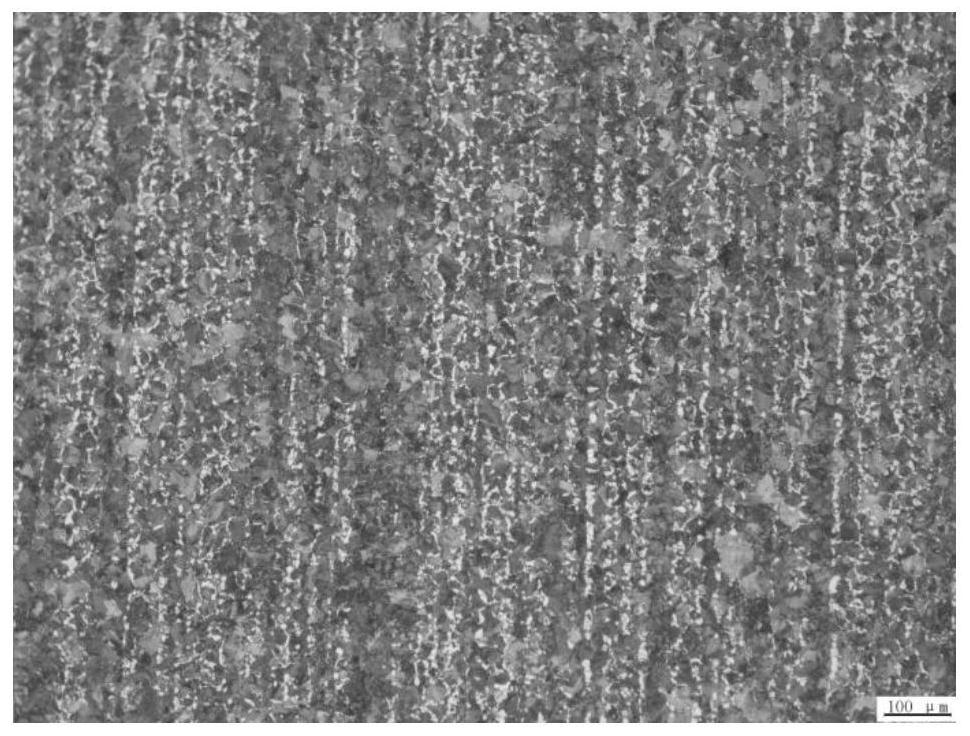

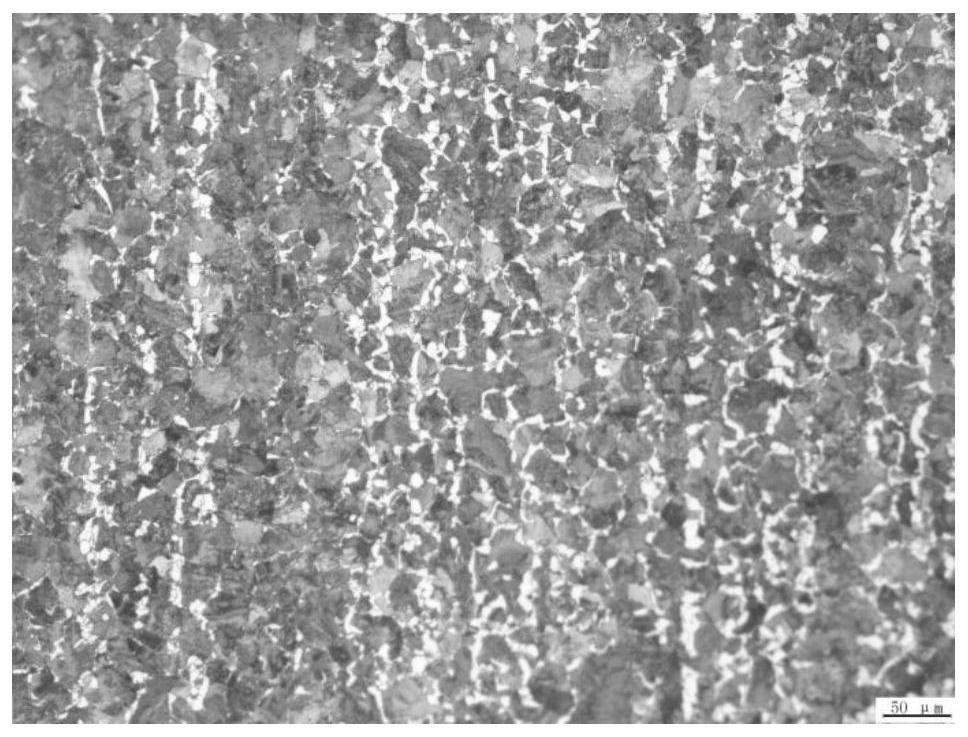

Image

Examples

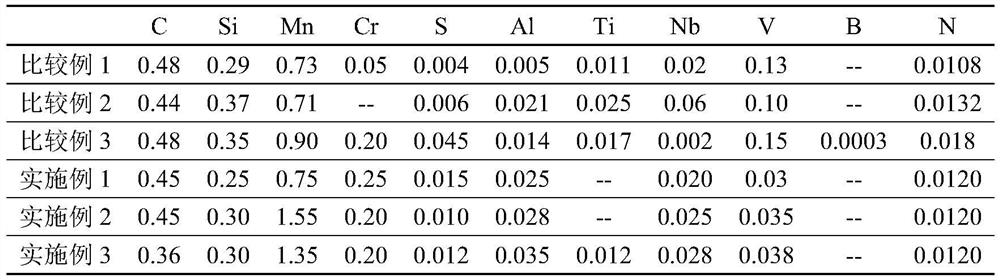

Embodiment 1

[0039] The diameter of the hot-rolled round steel in this embodiment is 60mm, and its chemical composition is calculated by mass percentage: C: 0.45%, Si: 0.25%, Mn: 0.75%, Cr: 0.25%, Al: 0.008%, S: 0.015% , Nb: 0.020%, V: 0.030%, N: 0.0120%, and the balance is iron and unavoidable impurity elements.

[0040] The above round steel is successively smelted by electric furnace and LF refined to produce molten steel; the molten steel is poured into a 250*250mm continuous casting billet with a low superheat of 15-30°C under full argon protection, and the continuous casting billet is slowly cooled in the pit for 32 hours; The cast billet is heated to 1200°C, held for 3 hours and released from the furnace; after descaling by high-pressure water once, it returns to the original path, and performs second descaling by high-pressure water to remove all surface oxide scales and promote cooling; Air cooling on the road and waiting for temperature. During the waiting period, the turning mac...

Embodiment 2

[0042] The diameter of the round steel involved in this embodiment is 60mm, and its chemical composition is calculated by mass percentage: C: 0.45%, Si: 0.30%, Mn: 1.55%, Cr: 0.20%, Al: 0.010%, S: 0.028%, Nb: 0.025%, V: 0.035%, N: 0.0120%, and the balance is iron and unavoidable impurity elements.

[0043] The above-mentioned round steel is sequentially smelted by converter and LF refined to produce molten steel; the molten steel is poured into a 300*340mm continuous casting billet with a low superheat of 15-30°C under argon protection throughout the whole process, and the continuous casting billet is slowly cooled in the pit for 32 hours; The cast billet is heated to 1200°C, held for 3 hours and released from the furnace; after descaling by high-pressure water once, it returns to the original route, and performs second descaling by high-pressure water to remove all surface oxide scales and promote cooling; then turn over in the reciprocating billet opener The roller table is ...

Embodiment 3

[0045] The diameter of the round steel involved in this embodiment is 60mm, and its chemical composition is calculated by mass percentage: C: 0.36%, Si: 0.30%, Mn: 1.35%, Cr: 0.20%, Al: 0.012%, S: 0.035%, Ti: 0.012%, Nb: 0.028%, V: 0.038%, N: 0.0150%, and the balance is iron and unavoidable impurity elements.

[0046] The above-mentioned round steel is sequentially smelted by converter and LF refined to produce molten steel; the molten steel is poured into a 250*250mm continuous casting billet with low superheat of 15-30°C under argon protection throughout the whole process, and the continuous casting billet is slowly cooled in the pit for 32 hours; The cast billet is heated to 1200°C, held for 3 hours and released from the furnace; after descaling by high-pressure water once, it returns to the original route, and performs second descaling by high-pressure water to remove all surface oxide scales and promote cooling; then turn over in the reciprocating billet opener The roller...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com