A kind of shielding method for preparing thermal spray thick coating

A thermal spraying and coating technology, applied in coating, metal material coating process, fusion spraying, etc., can solve problems such as difficulty in satisfying coating performance and production cycle, easy chipping, adhesion of protective tape and coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings.

[0022] Preparation of Thick Sealing Coating for Compressor Balance Disc

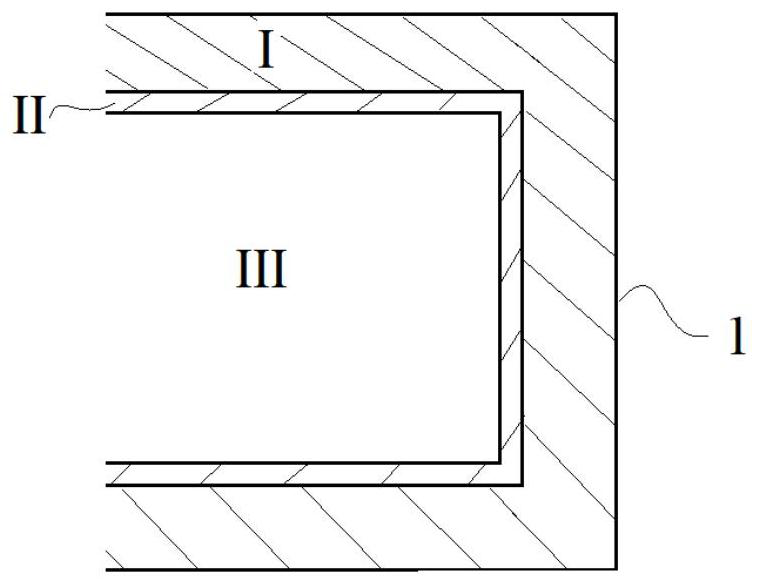

[0023] Step 1: Perform alcohol scrubbing and degreasing on the surface of the workpiece, use sandblasting protective tape to cover the non-coated parts, use 22-mesh white corundum sand and 0.8MPa press-in sand blasting to roughen the surface of the coated parts, and remove after roughening. Sandblasting protective tape, using clean compressed air to blow clean parts. Spray substrates such as figure 1 As shown, the sprayed substrate 1 can be divided into a non-sprayed zone I, a sprayed transition zone II, and a sprayed zone III.

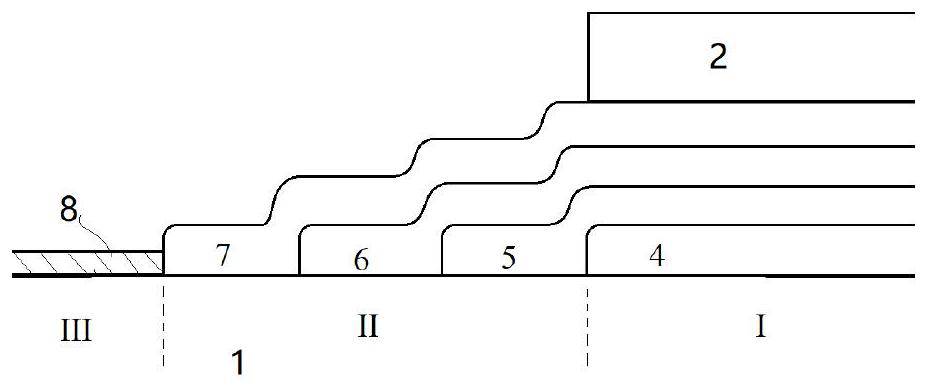

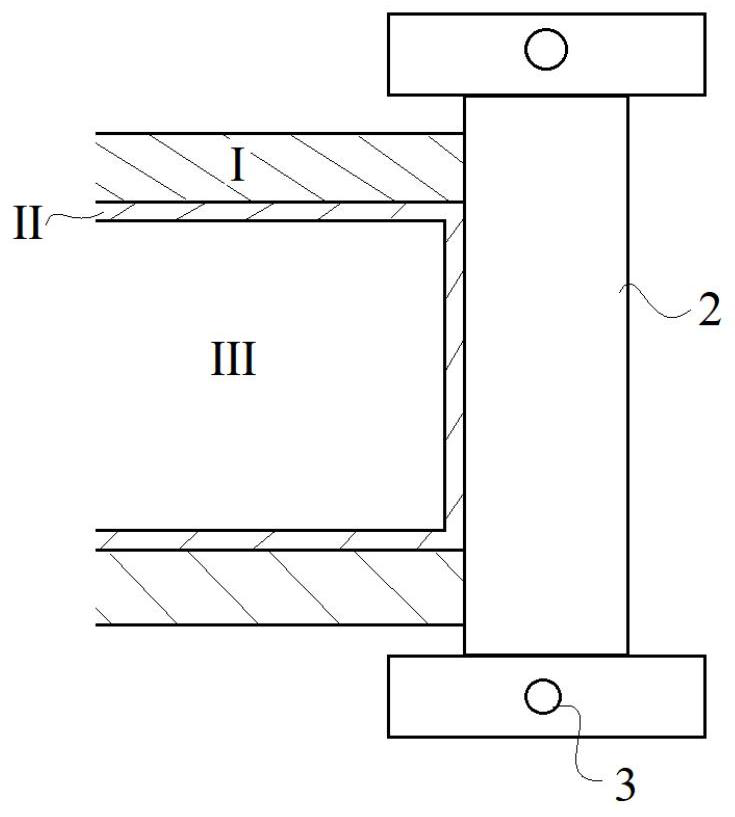

[0024] step 2, as figure 2 As shown, the surface adjacent to the sprayed surface is protected by protective tape from 4mm away from the edge of the sprayed surface. Extend 1mm to the spray area until it is flush with the edge of the spray area, and trim the edge of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com