Argon recycling method and system based on air separation system

An air separation system and argon technology, applied in the direction of cold treatment separation, liquefaction, solidification, etc., can solve the problems of large loss of liquid nitrogen, inability to recover liquid argon cold pump liquid and tank truck pressure relief argon, complex operation, etc., to achieve Safe and stable recovery, easy operation and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

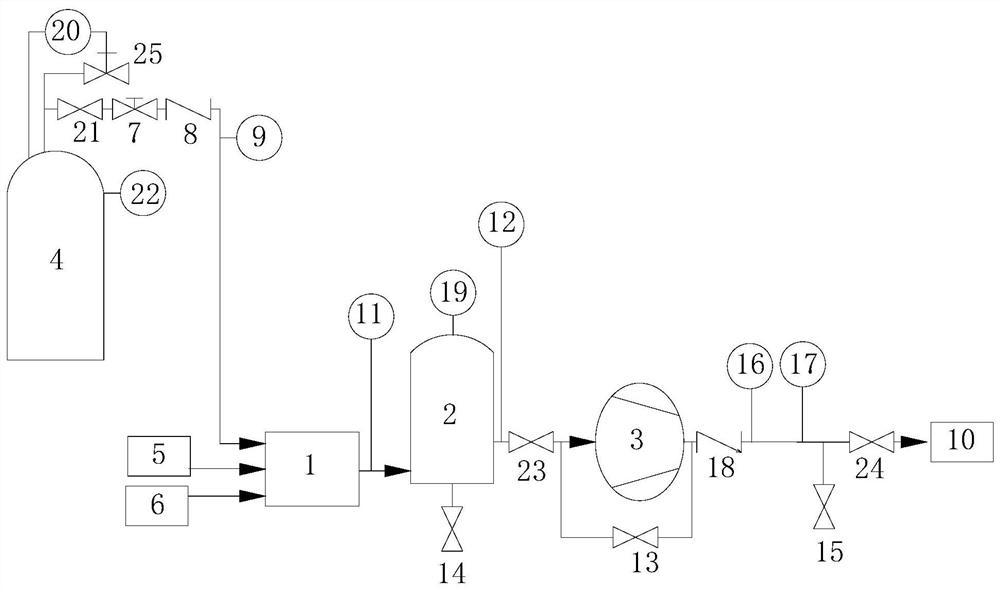

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments do not limit the present invention.

[0034] The invention mainly discloses an argon recovery method and system based on an air separation system. The recovery method is specifically:

[0035] The argon in the vent pipe of the argon storage tank 4, the air discharge pipe of the tank car 5, and the exhaust gas pipe of the charging car 6 are all sent to the water-bath vaporizer 1 for heat exchange. The heat exchange principle of the water-bath vaporizer 1 is the water-bath vaporizer 1 The coil is liquid argon, and the outside of the tube is water for heat exchange. The gaseous argon after heat exchange is temporarily stored in the argon buffer tank 2 for use when needed, and then compressed by the argon compressor 3 and then direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com