Energy-saving system of hot-blast heater for drying tea leaves and using method

An energy-saving system and hot blast stove technology, applied in tea drying, drying, dryer and other directions, can solve the problems of increasing energy consumption, heat energy loss, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

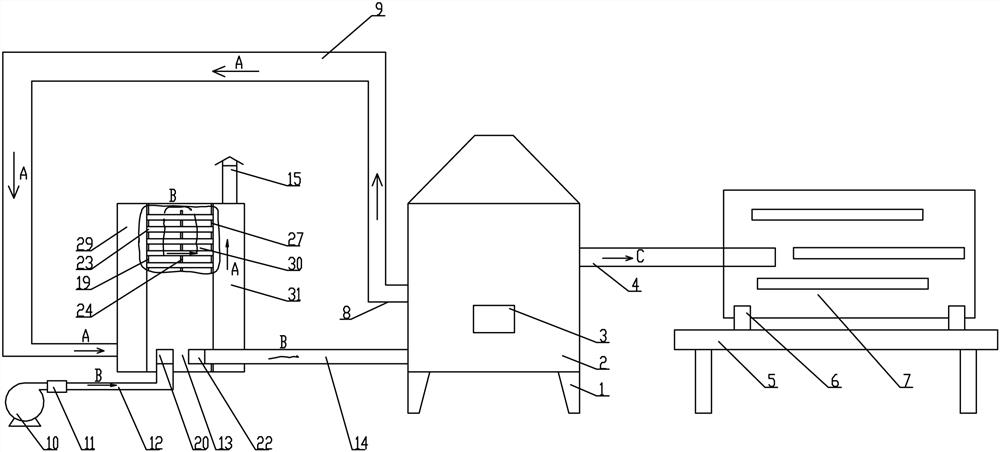

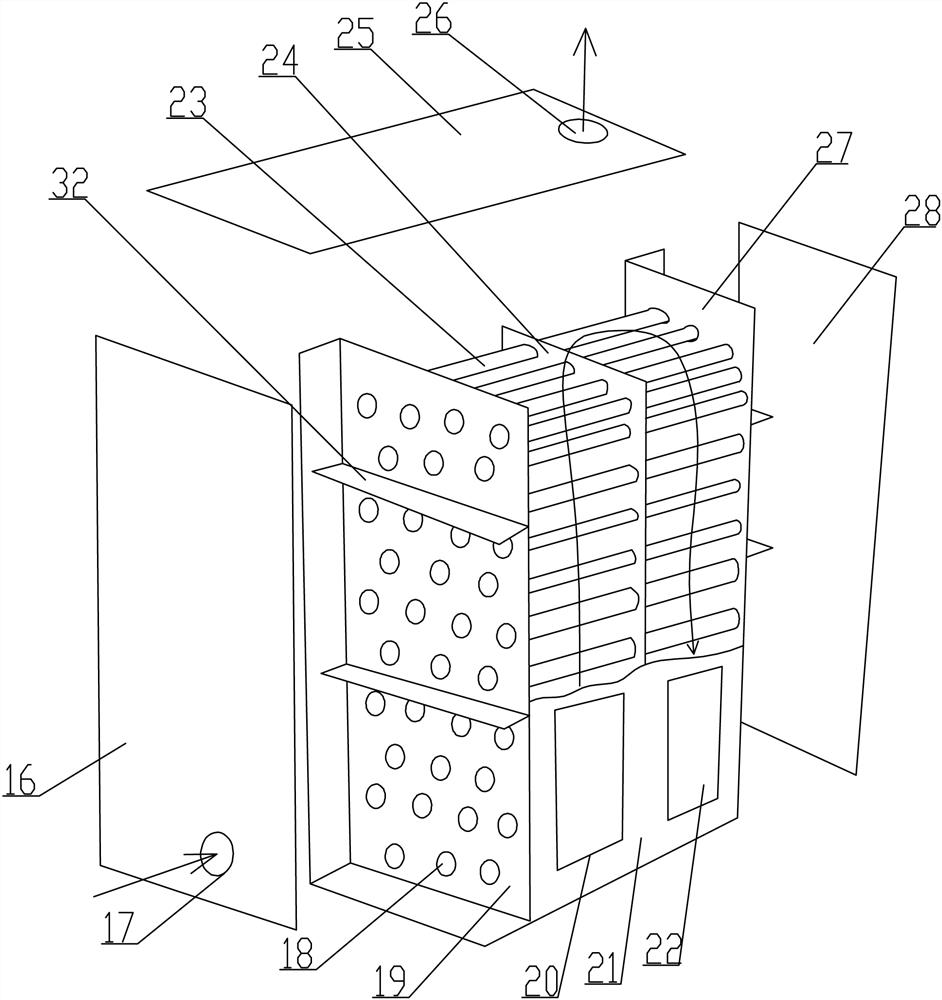

[0035] see Figure 1-2 , an energy-saving system for tea drying hot air stove, which includes a combustion furnace 2, the top of the combustion furnace 2 is provided with a flue gas outlet 8, and the flue gas outlet 8 passes through the flue gas return pipe 9 and the flue gas of the waste heat exchange box 13 The inlet 17 is connected, the top of the other side of the waste heat exchange box 13 is equipped with a smoke exhaust pipe 15, the bottom side of the front side wall of the waste heat exchange box 13 is installed with an air inlet pipe 12, and the other side of the air inlet pipe 12 is A blower 10 is installed at one end, and an air outlet pipe 14 is installed on the other side of the bottom of the front side wall of the waste heat exchange box 13, and the air outlet pipe 14 communicates with the air supply port of the combustion furnace 2, and The hot air outlet is connected to the chain plate dryer 7 through the hot air drying pipe 4 . This energy-saving system great...

Embodiment 2

[0046] The method for using the energy-saving system of the tea drying hot air stove includes the following steps:

[0047] Step 1: Connect the combustion furnace 2 and the waste heat exchange box 13 through the flue gas return pipe 9;

[0048] Step 2: Connect the combustion furnace 2 and the chain plate dryer 7 through the hot air drying pipe 4;

[0049] Step 3: Connect the waste heat exchange box 13 and the combustion furnace 2 through the air outlet pipe 14;

[0050] Step 4: Connect the blower 10 with the waste heat exchange box 13 through the air inlet pipe 12;

[0051] Step 5: Add fuel to the interior of the combustion furnace 2, and start the blower 10 to pass air at normal temperature into the preheating cavity 30 of the waste heat exchange box 13. At this time, the air will enter the air outlet pipe 14 from the air outlet 22 after passing through the turbulence , and then enter the inside of the combustion furnace 2 through the air outlet pipe 14, and discharge from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com