Automatic packaging detection line for fuel cell membrane electrode

A fuel cell membrane and detection line technology, applied in the direction of fuel cells, battery electrodes, circuits, etc., can solve the problems of scratches or damage to membrane materials, unsatisfactory detection effect of membrane electrode air tightness, etc., to improve production efficiency, improve Product quality and process consistency, the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

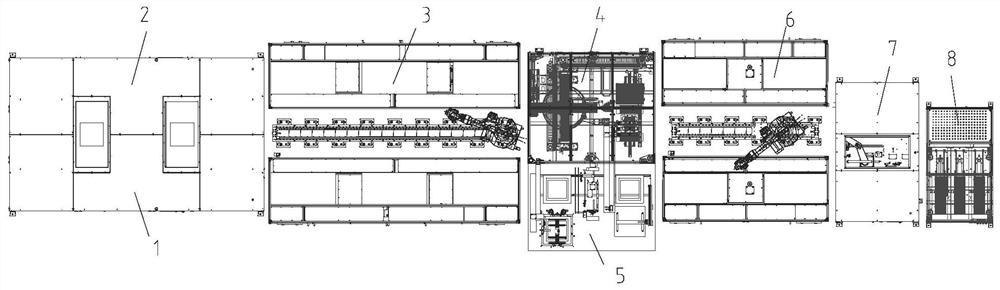

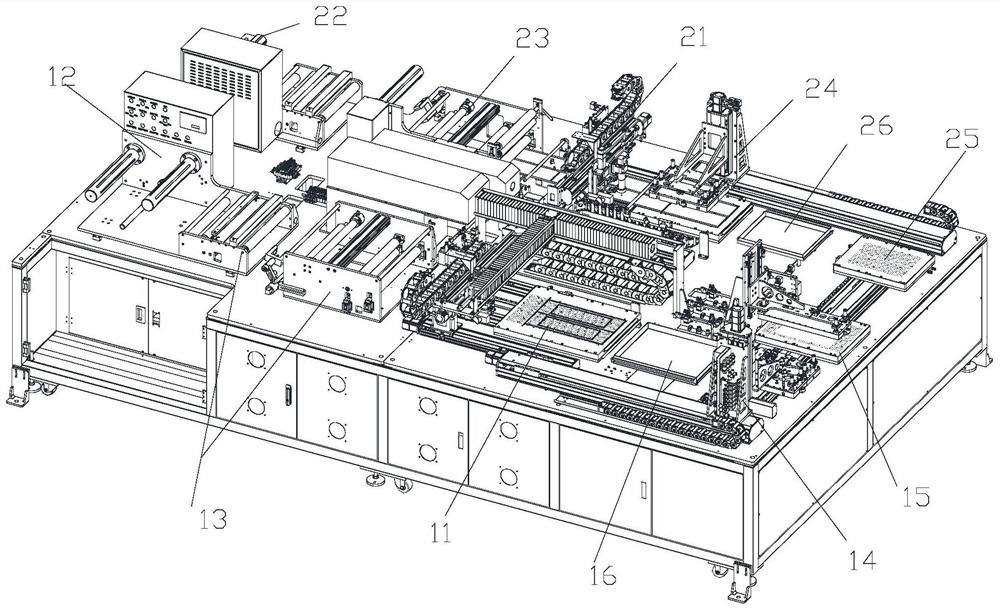

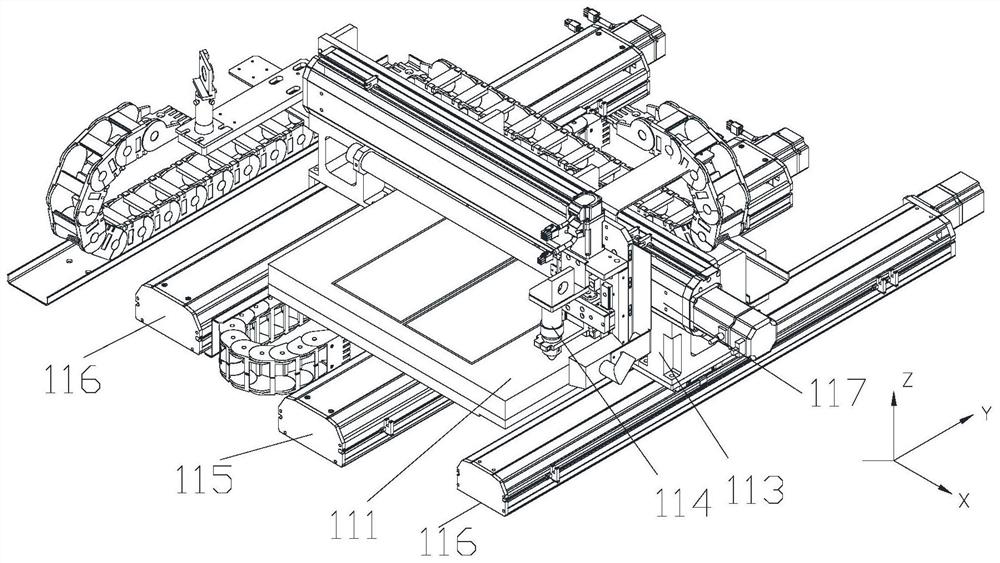

[0088] Such as Figure 1 to Figure 21 shown. In this embodiment, a fuel cell membrane electrode automatic packaging detection line includes:

[0089] A frame film cutting device 1 for cutting out the cathode frame film and the anode frame film;

[0090] CCM cutting device 2 for cutting CCM;

[0091] A five-in-one hot pressing device 3 for stacking the cathode frame film and the anode frame film on both sides of the CCM, and vacuum hot pressing to form a five-layer film electrode;

[0092] Marking and detection device 4 for marking and visual inspection of the five-layer membrane electrode;

[0093] A gas diffusion layer cutting device 5 for cutting out the cathode gas diffusion layer and the anode gas diffusion layer;

[0094] A seven-in-one hot pressing device 6 for stacking the cathode gas diffusion layer and the anode gas diffusion layer on both sides of the five-layer membrane electrode and performing hot pressing to form a seven-layer membrane electrode;

[0095] A m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com