Remediation material for reducing migration-state lead ions in soil and preparation method thereof

A repair material and lead ion technology, applied in the field of soil repair, can solve the problems of low treatment efficiency in reducing lead ion content, secondary pollution of repair materials, uneven quality, etc., achieve excellent insect resistance, avoid secondary pollution, improve The effect of throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

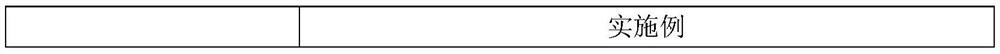

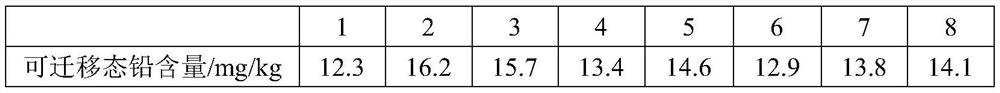

Examples

Embodiment 1

[0014] A repairing material for reducing mobile lead ions in soil, the preparation method of which comprises the following steps:

[0015] Weigh 68 parts of eggshell powder and place them in a muffle furnace for heat treatment at 500°C for 3 hours. After cooling, transfer the material, 100 parts of polylactic acid, 8 parts of SE-10 emulsifier and 19 parts of ginkgo peel powder to a low-temperature pulverizer. Control the crushing temperature at -20°C, crush and sieve to 100 mesh, transfer the material to the extruder, use the extruder to extrude and granulate at a temperature of 229°C, transfer the material, 180 parts of acetic acid and 145 parts of water to the hydrothermal In the reaction kettle, maintain the hydrothermal reaction temperature at 105°C for 0.5h. The product is washed with water several times, filtered, and dried. Under the ambient pressure of 0.05MPa, the material is impregnated in 21 parts of thiourea and 0.8 parts of polyacrylamide 5% (wt.%) mixed aqueous s...

Embodiment 2

[0017] A repairing material for reducing mobile lead ions in soil, the preparation method of which comprises the following steps:

[0018] Weigh 52 parts of eggshell powder and place it in a muffle furnace for heat treatment at 500°C for 3 hours. After cooling, transfer the material, 100 parts of polylactic acid, 5 parts of SE-10 emulsifier and 15 parts of ginkgo peel powder to a low-temperature pulverizer. Control the crushing temperature at -20°C, crush and sieve to 100 mesh, transfer the material to the extruder, use the extruder to extrude and granulate at a temperature of 216°C, transfer the material, 156 parts of acetic acid and 120 parts of water to the hydrothermal In the reaction kettle, maintain the hydrothermal reaction temperature at 90°C for 1.5 hours. The product is washed with water for many times, filtered, and dried. 5% (wt.%) mixed aqueous solution, control the immersion temperature at 30°C for 3h, and after freeze-drying at -30°C, spray a saturated aqueous s...

Embodiment 3

[0020] A repairing material for reducing mobile lead ions in soil, the preparation method of which comprises the following steps:

[0021] Weigh 85 parts of eggshell powder and place it in a muffle furnace for heat treatment at 500°C for 3 hours. After cooling, transfer the material, 100 parts of polylactic acid, 13 parts of SE-10 emulsifier and 33 parts of ginkgo peel powder to a low-temperature pulverizer. Control the crushing temperature at -20°C, crush and sieve to 100 mesh, transfer the material to the extruder, use the extruder to extrude and granulate at a temperature of 239°C, transfer the material, 210 parts of acetic acid and 165 parts of water to the hydrothermal In the reaction kettle, maintain the hydrothermal reaction temperature at 130°C for 0.2h. The product is washed with water several times, filtered, and dried. 5% (wt.%) mixed aqueous solution, control the immersion temperature at 30°C for 3h, and after freeze-drying at -30°C, spray a saturated aqueous solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com