Device and method capable of recycling waste heat of neodymium iron boron waste roasting kiln

A neodymium-iron-boron and roasting furnace technology, applied in furnace control devices, waste heat treatment, furnaces, etc., can solve the problems of poor recycling effect and inability to utilize waste heat, and achieve the goal of enhancing utilization, reducing waste heat loss, and expanding contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

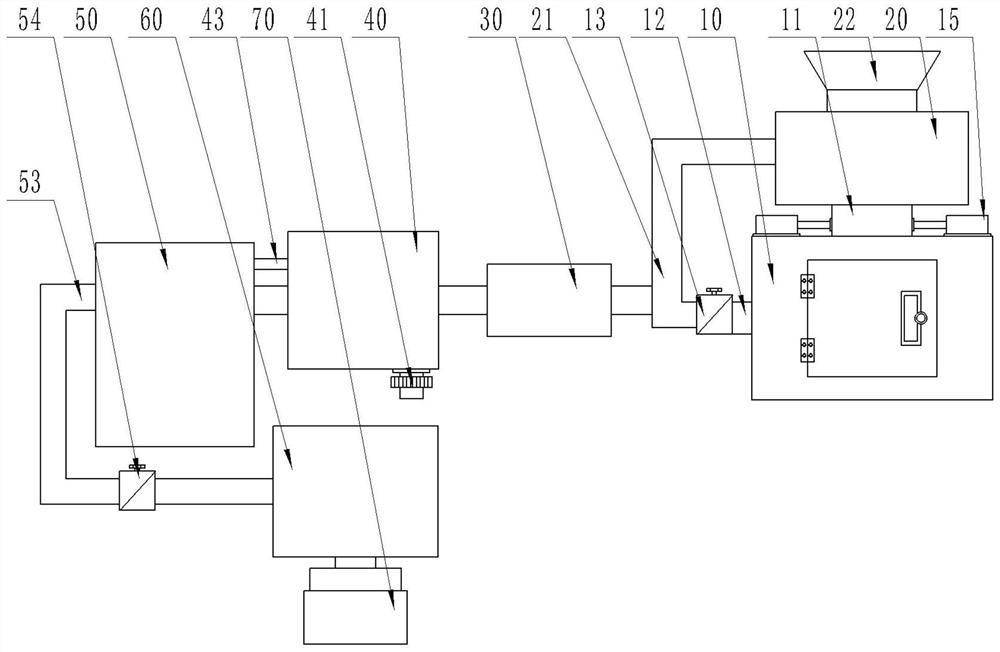

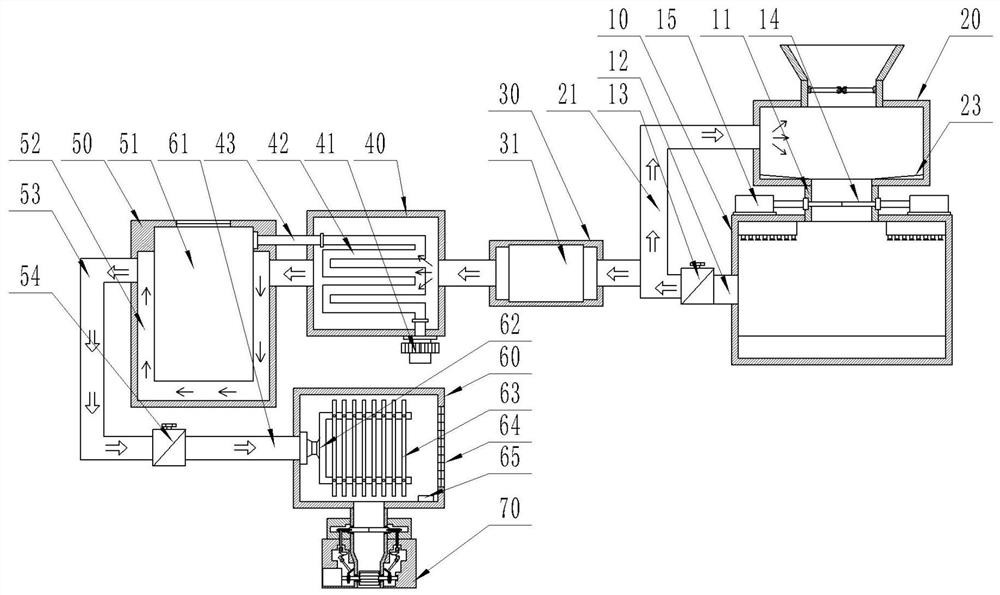

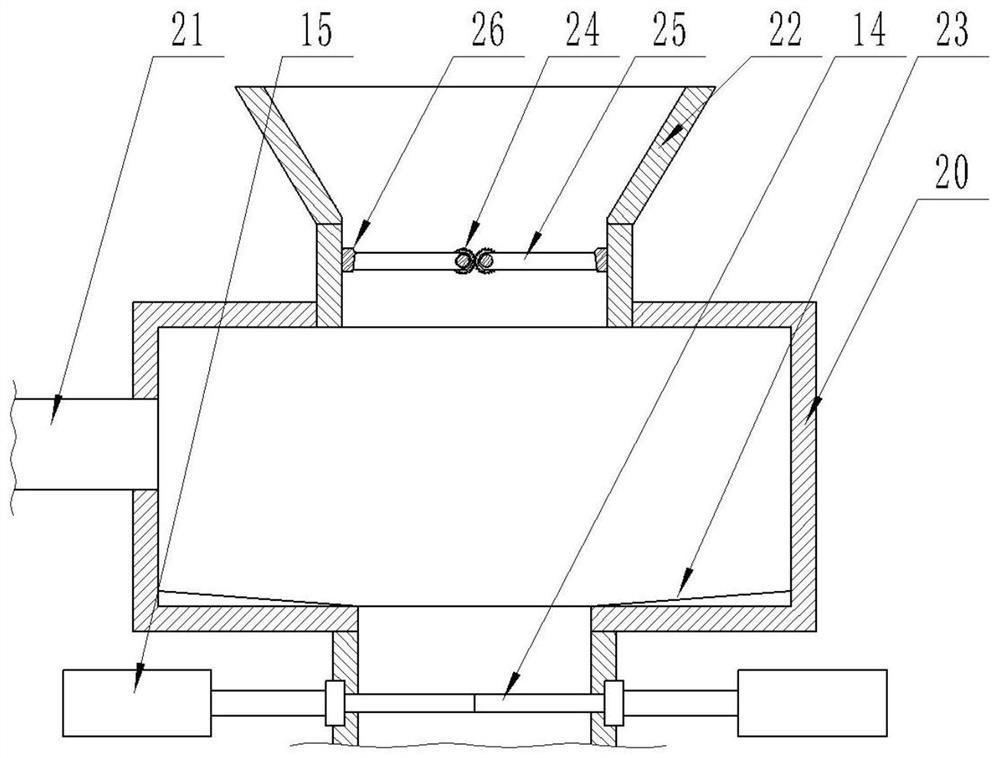

[0079] A device that can recycle the waste heat of a kiln for roasting NdFeB waste, wherein, such as Figure 1-3 As shown, it includes: a roasting furnace 10 , a control valve 13 , a material partition 14 , a preheating bin 20 , a hopper 22 , a synchronous gear 24 , bias shrapnel, and a heat shield 25 .

[0080] The calciner 10 has a feed port 11 and an exhaust port 12 , and the feed port 11 is located at the upper end of the calciner 10 . The exhaust port 12 is located at the left side of the roasting furnace 10 .

[0081] The regulating valve 13 is arranged at the exhaust port 12 . The material partition 14 is arranged in the feed port 11 to seal the feed port 11 .

[0082]The preheating bin 20 is arranged on the upper end of the roasting furnace 10 , and the preheating bin 20 is connected to the feed port 11 . The hopper 22 communicates with the preheating bin 20 .

[0083] Such as image 3 As shown, the synchronous gear 24 is disposed in the hopper 22 . The bias shra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com