Design method of heat dissipation system

A heat dissipation system and design method technology, applied in the field of heat dissipation systems, can solve problems such as simulation accuracy, air volume calculation accuracy to be improved, and heat dissipation system simulation design process complexity, etc., to improve calculation accuracy, improve accuracy, and improve system efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

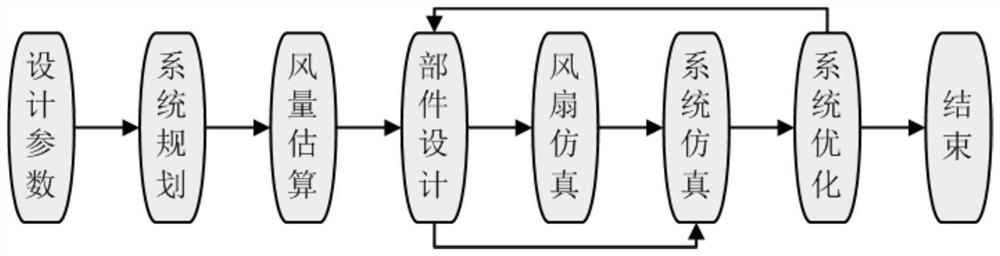

[0024] The invention provides a heat dissipation system design method, such as figure 1 As shown, the specific steps of the heat dissipation system design method are as follows:

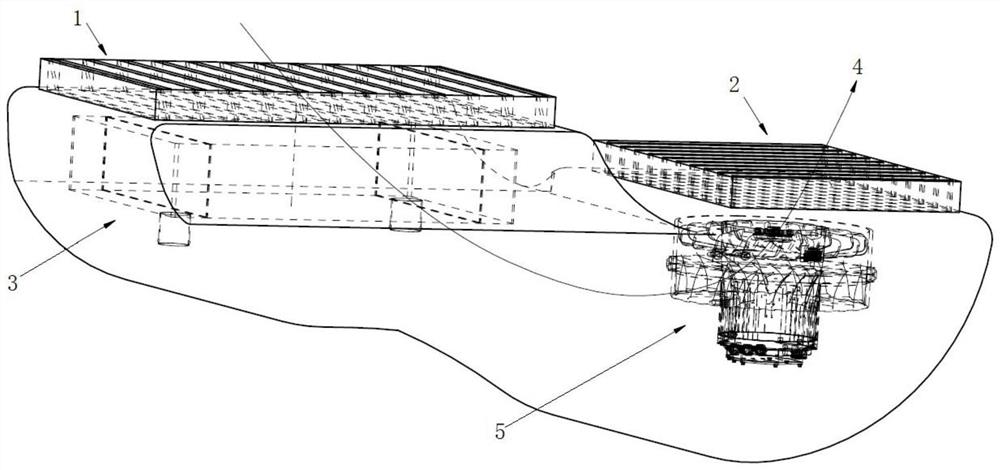

[0025] Step 1: According to the given heat dissipation system design parameters such as the heat exchange rate Q, etc., the heat dissipation system scheme planning is carried out. The heat dissipation system design mainly includes the radiator 3, the air duct 4, the intake louver 1, the exhaust louver 2 and the fan 5 design, such as figure 2 shown, and according to the formula M=Q / [C P *(△T 1 +△T 2 )] Preliminary estimation of the air volume of the cooling system, where:

[0026] M is the air flow rate (kg / s);

[0027] Q is heat transfer (kW);

[0028] C P Specific heat of air at constant pressure (kJ / kg°C);

[0029] ΔT 1 Air temperature rise caused by heat exchange (°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com