Tobacco component suitable for electronic cigarette liquid and its processing and application method

A tobacco and solid-liquid separation technology, which is applied in the fields of application, tobacco, and tobacco treatment, can solve the problems of missing characteristic aroma components of tobacco, incomplete aroma performance, and many macromolecular impurities, so as to improve the richness and content, improve Richness, clean and comfortable taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The present invention provides a method for preparing a tobacco component (i.e. tobacco flavoring substance) applied to an electronic cigarette liquid, comprising the following steps:

[0071] (1) Step-by-step extraction of tobacco raw materials:

[0072] The first extraction: the raw material of mixed extractant 1 is prepared by mixing high-concentration ethanol (ethanol: water mass ratio = 90:10-99:1) and propylene glycol at a mass ratio of 95:5-100:0. Put the tobacco raw material into the extraction tank with a reflux device, add the mixed extractant 1 for heating and stirring extraction, the extraction temperature is 60-80°C, the mass ratio of the tobacco raw material to the extractant 1 is 1:5-1:7, and the extraction time is 0.5 ~1.5 hours. After extraction, the extract is separated from the raw material by methods including natural sedimentation, suction filtration, centrifugation and the like; the obtained first extraction liquid is used for future use, and the ...

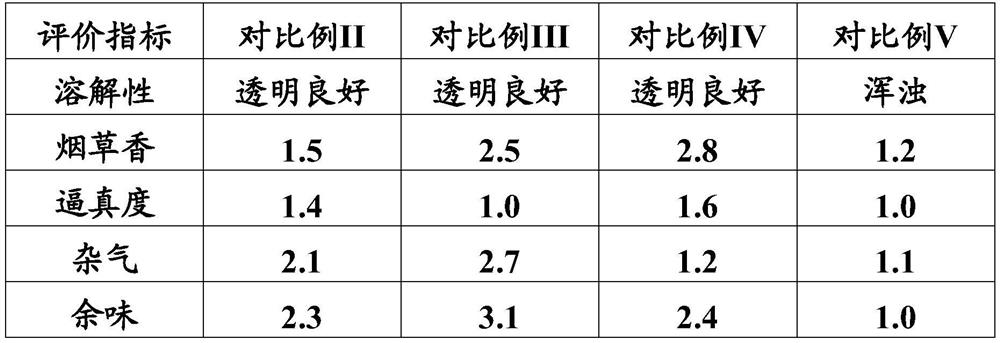

Embodiment I-II、 comparative example I

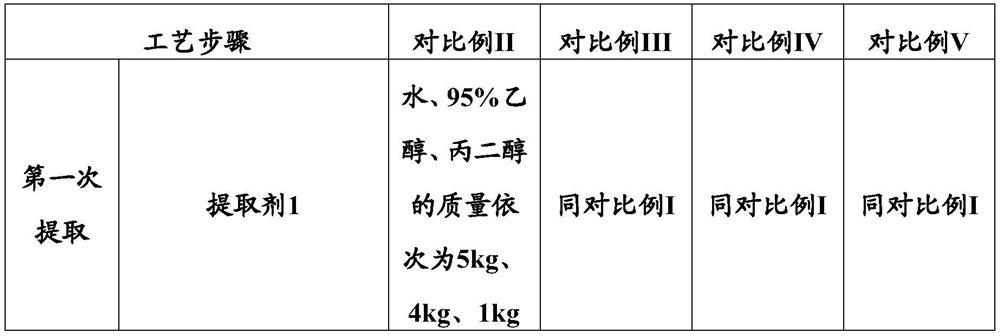

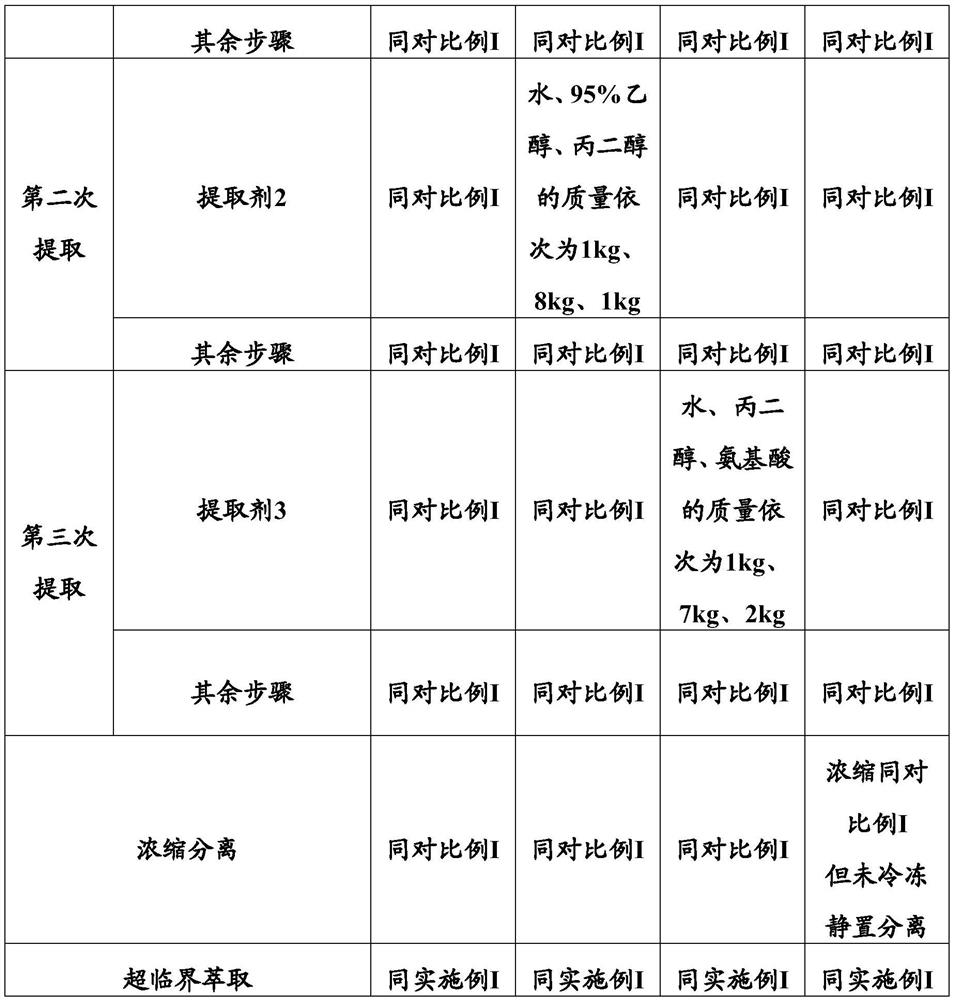

[0090] Comparative example I

[0091] For the first extraction, 9.8kg of 95% ethanol (mass percentage of ethanol and water) was mixed with 0.2kg of propylene glycol to prepare mixed extractant 1. Weigh 1 kg of pulverized mixed tobacco flakes, add 5 kg of mixed extractant 1, heat and stir in a constant temperature oil bath, and extract for 1 hour at a temperature of 65°C, then seal the bottle mouth with a 300-mesh filter cloth, pour it out and collect Extract 1.

[0092] For the second extraction, 5kg of distilled water, 3.5kg of 95% ethanol (mass percentage of ethanol and water) and 1.5kg of propylene glycol were mixed to prepare mixed extractant 2. Add 5kg of mixed extractant 2 to the tobacco raw material flask after the first extraction, heat and stir in a constant temperature oil bath, and extract at a temperature of 80°C for 1 hour, then seal the bottle mouth with a 300-mesh filter cloth, pour it out and collect Extract 2.

[0093] For the third extraction, 1 kg of dist...

Embodiment I

[0096] According to the method of comparative example 1, obtain 5kg of extracting solution, use supercritical carbon dioxide extraction equipment, use 40kg carbon dioxide gas altogether, 2kg ethanol is as entrainer, under the condition of 40 ℃ of extraction kettle pressure, dynamic extraction 2 hours, divide Extraction until all 5kg extracts are used for extraction. The tobacco components were collected and combined in the separatory kettle to obtain about 4.5 kg of tobacco components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com