Dust remover box structure of electric dust remover

A box structure, electrostatic precipitator technology, applied in electrode structure, external electrostatic separator, power supply technology, etc., can solve the problems of large manual welding error, insufficient washing intensity, uneven distribution of corona, etc. The effect of high slot position, increasing the probability of being adsorbed, and increasing the efficiency of charged contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

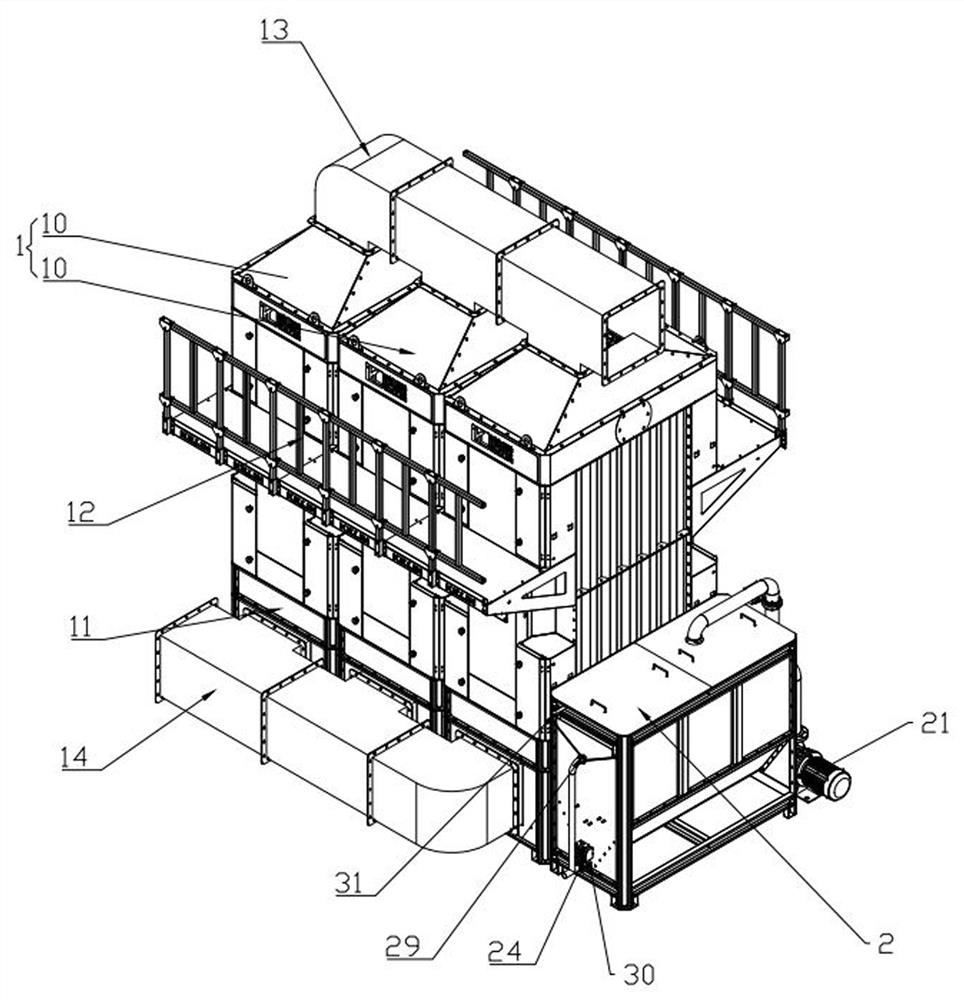

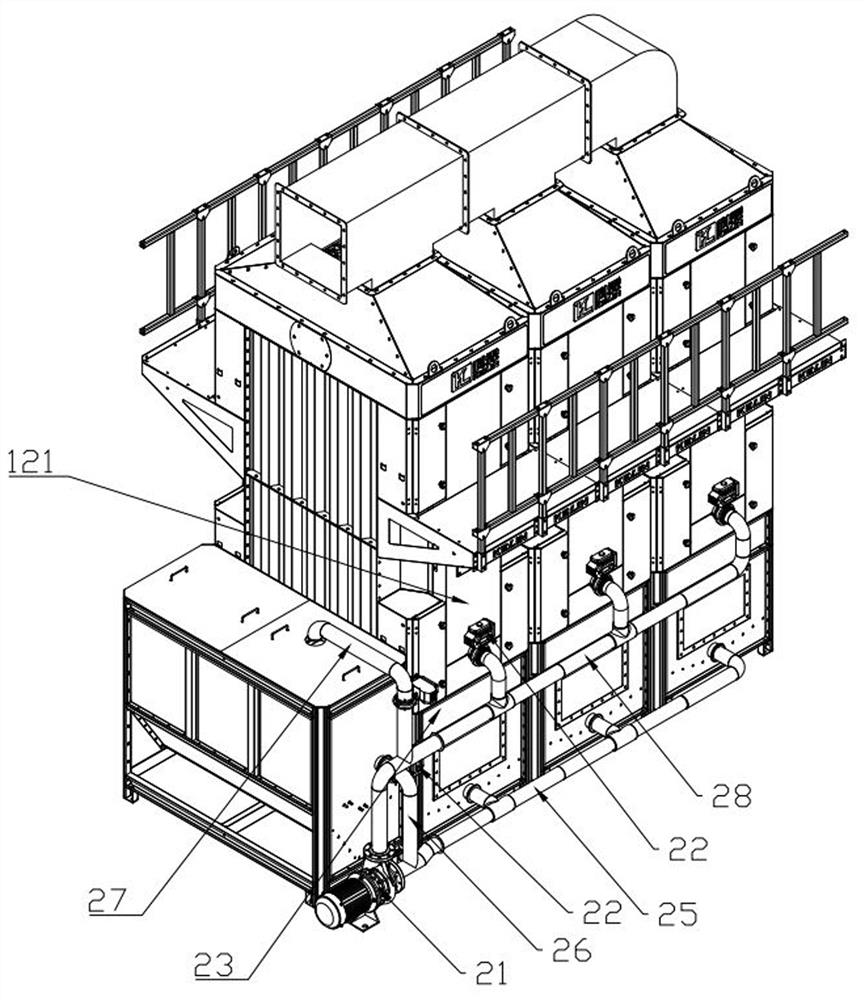

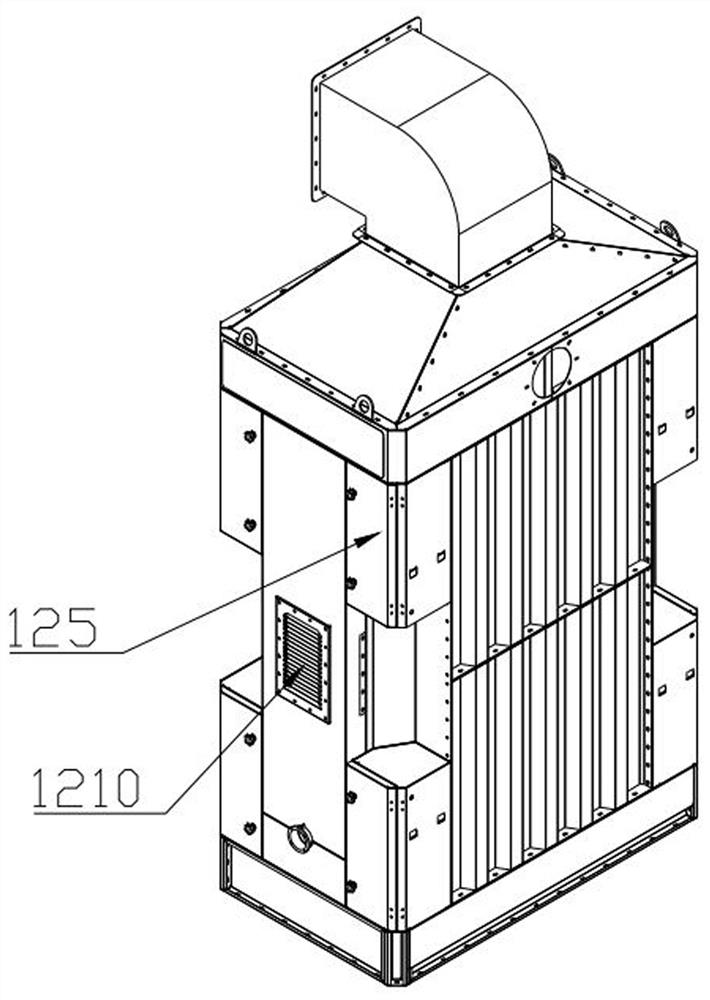

[0044] like Figure 1 to Figure 17 As shown, a wet electrostatic precipitator described in this embodiment includes a precipitator main body 1 and a water tank 2. The precipitator main body 1 is composed of a plurality of precipitator main units 10, and each of the precipitator main units 10 are arranged side by side, and each dust collector main unit 10 can work independently. Each dust collector main unit 10 includes a water collection tank 11, a dust collector body 12 and an air outlet cover 13 arranged from bottom to top. The bottom of the dust collector body 12 is closely connected by bolts, the bottom of the air outlet cover 13 is closely connected with the top of the dust collector body 12 by bolts, the side of the water collecting tank 11 is provided with an air inlet 14, and the air outlet cover 13 is Inverted bucket shape, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com