An insulation and heat conduction device applied to high-voltage optical communication equipment

It is a technology of insulation, heat conduction and optical communication, which is applied in the direction of modification through conduction and heat transfer, cooling/ventilation/heating modification, circuit arrangement on the support structure, etc., which can solve the impact of the electrical isolation performance of the shielding shell, and the easy formation of air holes and cracks , Poor injection molding performance and other issues, to achieve good machinability, prevent discharge and creepage, and high material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to meet the insulation requirements and heat dissipation requirements of submarine high-voltage optical communication equipment at the same time, and have better electrical isolation performance, the present application provides an insulating and heat-conducting device applied to high-voltage optical communication equipment through the following embodiments.

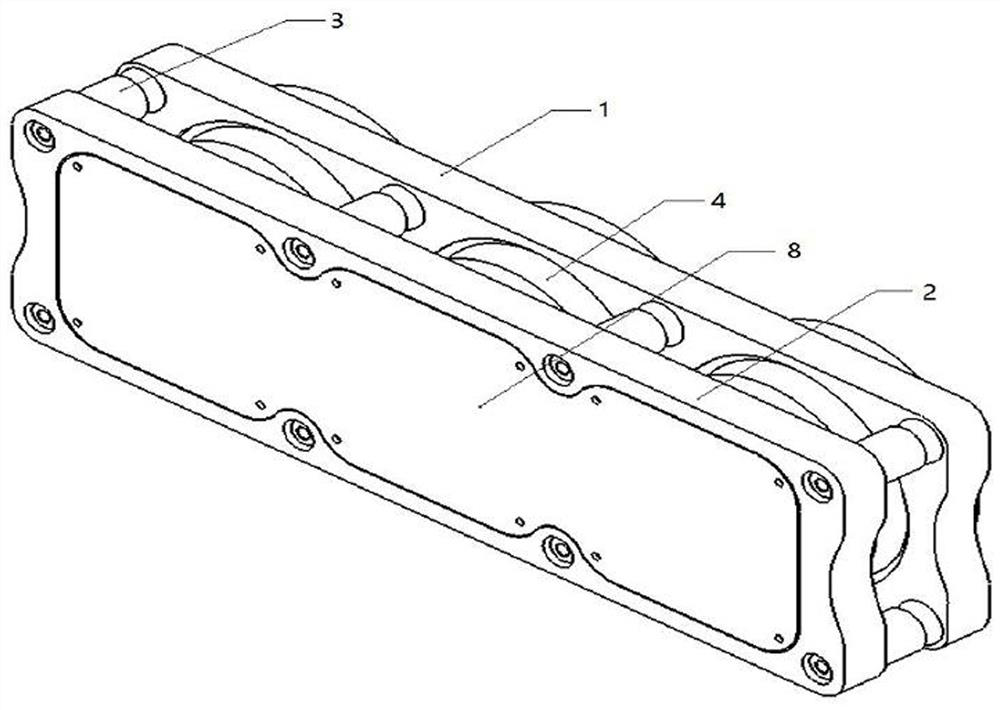

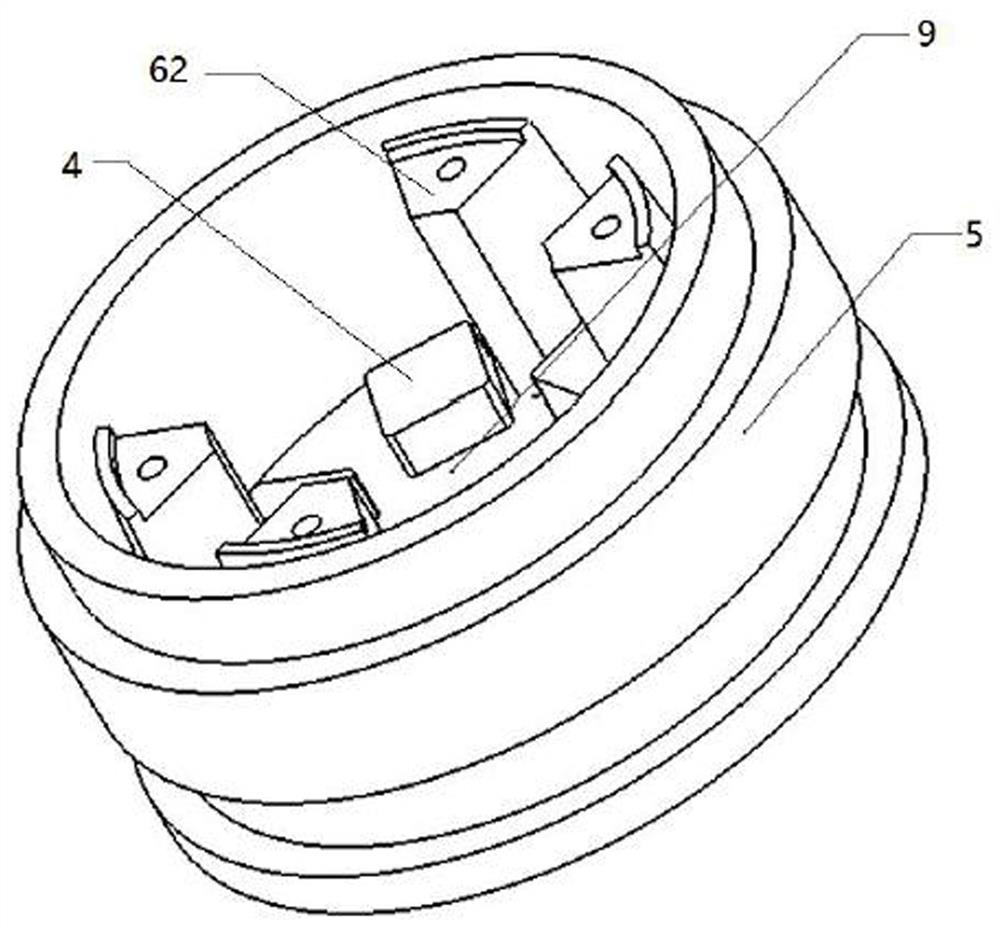

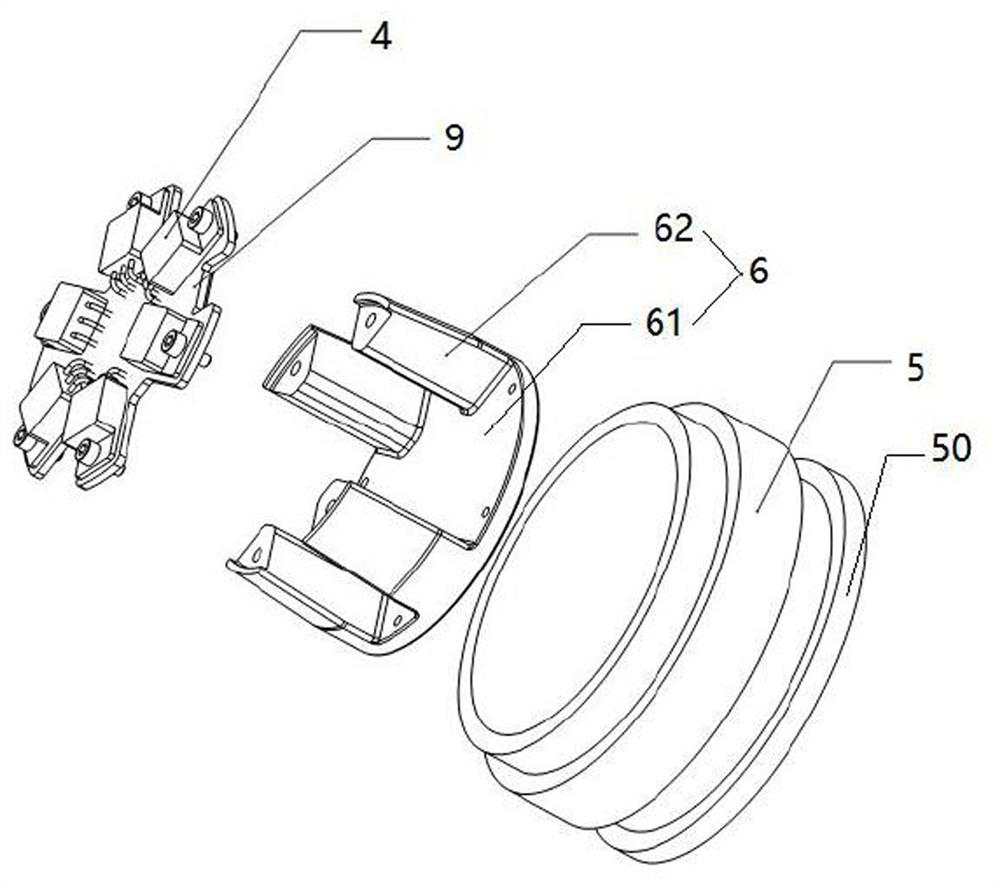

[0032] see figure 1 , the embodiment of the present application discloses an insulating and heat-conducting device applied to high-voltage optical communication equipment, comprising: a bracket 1 , a cover plate 2 , a plurality of connecting posts 3 and at least one ceramic insulating pot 5 for installing a power device 4 .

[0033] One end of the plurality of connecting columns 3 is jointly fixed on the cover plate 2 , and the other ends are jointly fixed on the bracket 1 . In an implementation manner, screws can be used to fix the connecting column 3 with the bracket 1 and the cover plate 2 respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com