A drilling device for a micro-valve body for a forklift and its production process

A drilling device and micro-valve technology, applied in the driving device, feeding device, boring/drilling and other directions, can solve the problems of low drilling efficiency and complicated drilling process, so as to improve the drilling efficiency and simplify the drilling process. Production process flow, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

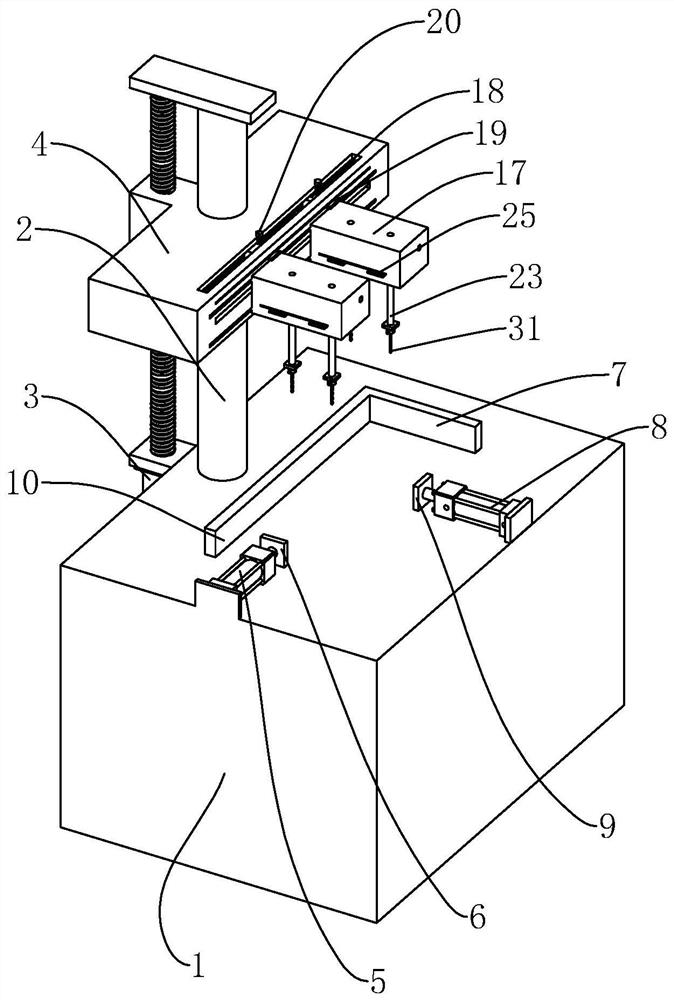

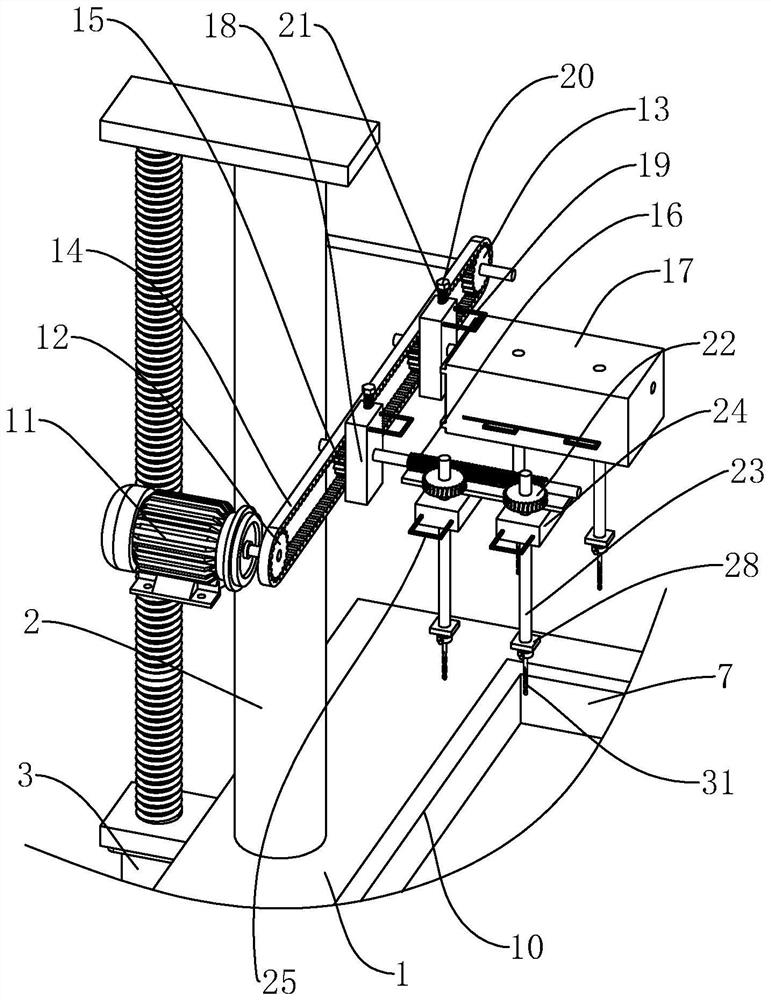

[0044] refer to figure 1 and figure 2 , the invention discloses a drilling device for a micro-valve body for a forklift, which comprises a body 1 which is in a square shape. The body 1 is fixed with a vertical lifting rod 2, and the lifting rod 2 is slidably connected with a horizontal lifting frame 4. The body 1 is fixed with a vertical lifting motor 3, and the output shaft of the lifting motor 3 runs through the lifting frame 4 and It is threadedly connected with lifting frame 4. The operator places the valve body that needs to be drilled on the body 1, starts the lifting motor 3, the lifting motor 3 rotates and then drives the lifting frame 4 to move up and down through the output shaft of the lifting motor 3, and the height of the lifting frame 4 can be adjusted up and down. The lifting frame 4 is fixed with a horizontal driving motor 11, and the side of the lifting frame 4 away from the lifting rod 2 is connected with a drill bit 31. The driving motor 11 rotates to dri...

Embodiment 2

[0056] A production process for a micro-motion valve body for a forklift, comprising the following steps:

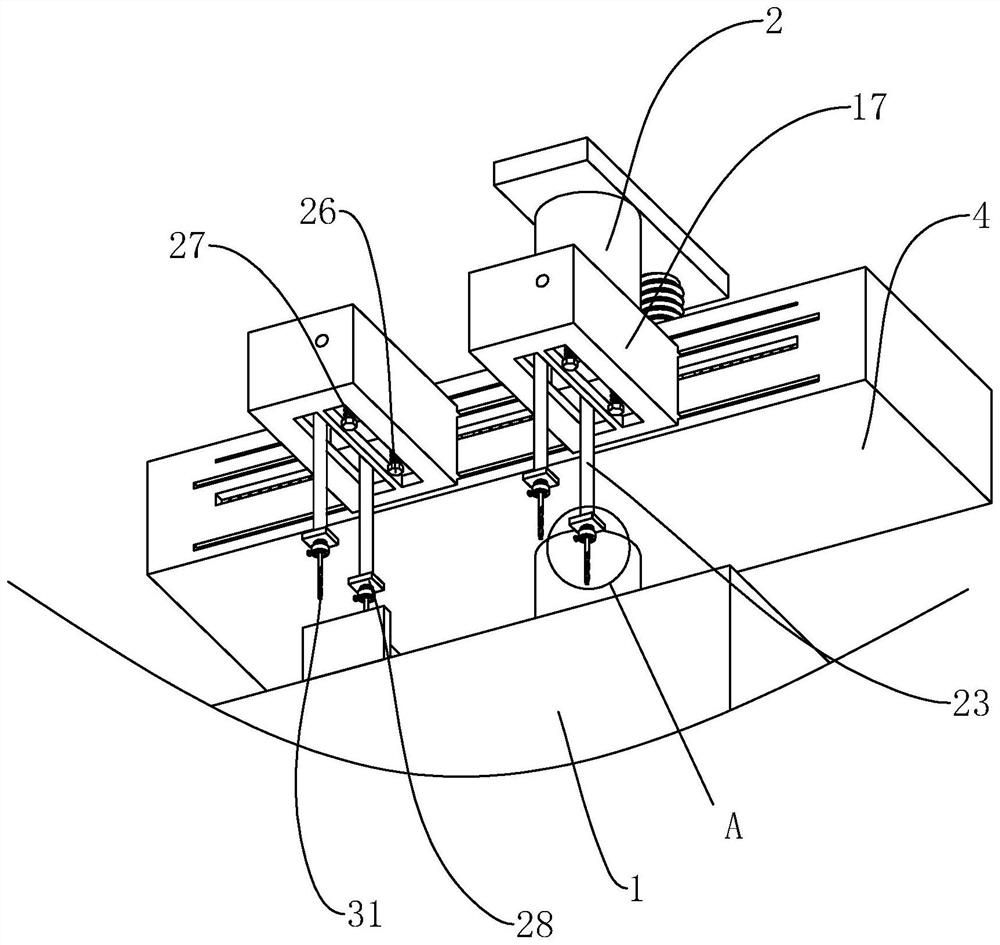

[0057] S1 The operator first places the valve body that needs to be drilled on the body 1, starts the clamping cylinder 1 5 and the clamping cylinder 2 8, and passes through the clamping plate 1 6 and the fixing plate 1 7, the clamping plate 2 9 and the fixing plate Two 10 cooperate with each other, and then clamp and fix the valve body;

[0058] S2 selects the drill bit 31 that is suitable for drilling holes on the valve body, first loosens the fastening ring 30, and then installs the drill bit 31 in the jaw 29, then tightens the fastening ring 30, and then tightens the fixing bolt 32 until the fixing bolt 32 Interfere with the jaws 29 to fix the position of the drill bit 31;

[0059] S3 adjust the distance between the drill bit 31 and the drill bit 31 along the direction of the drive tooth chain 14 according to the specific position of the hole drilled on the valve bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com