Two-in-one limiter test platform and test method for determining speed and force

A speed limiter and test bench technology, which is applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve the problems of poor versatility, low detection efficiency, cumbersome operation, etc., and achieve complete functions and good versatility , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

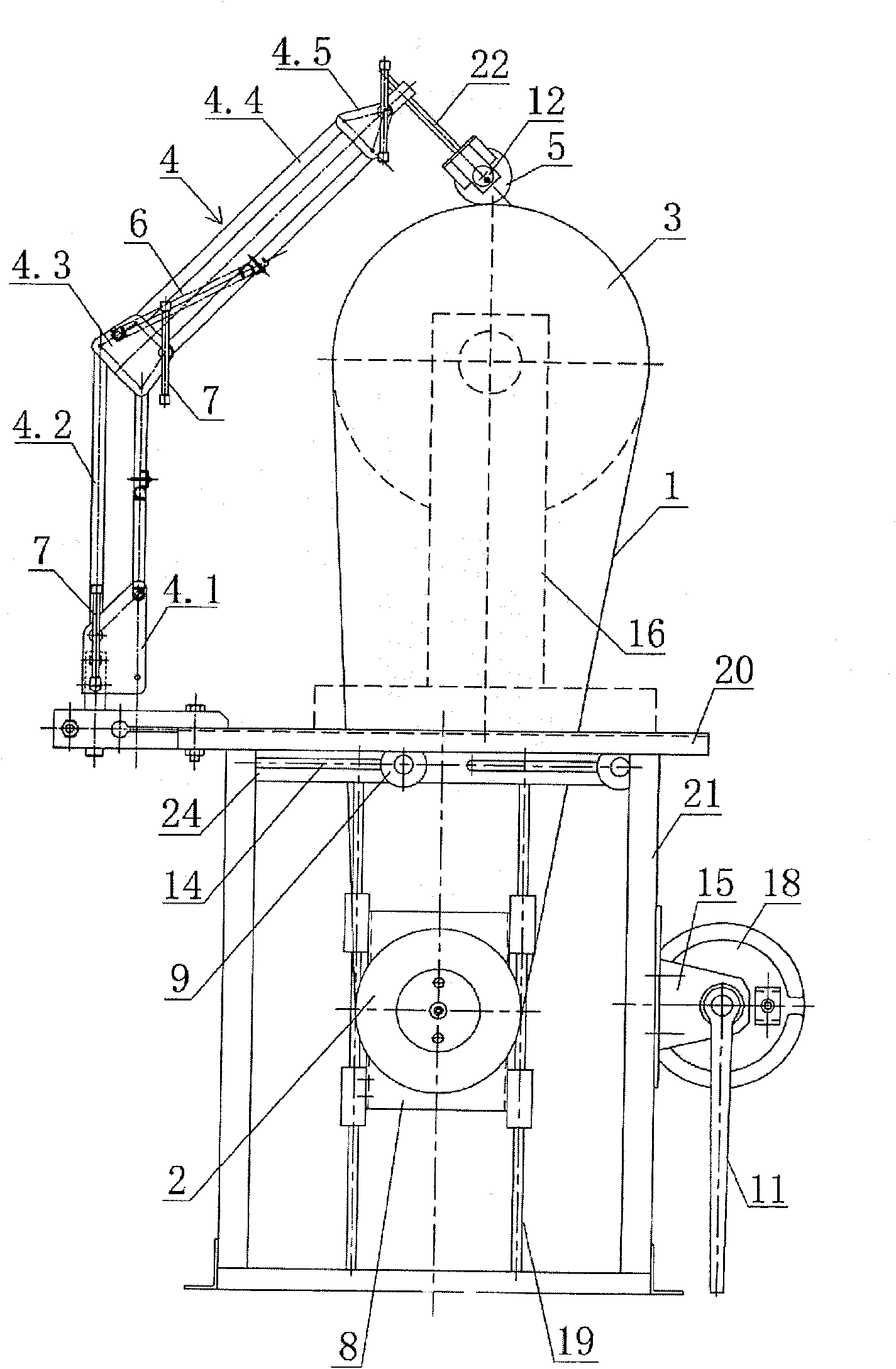

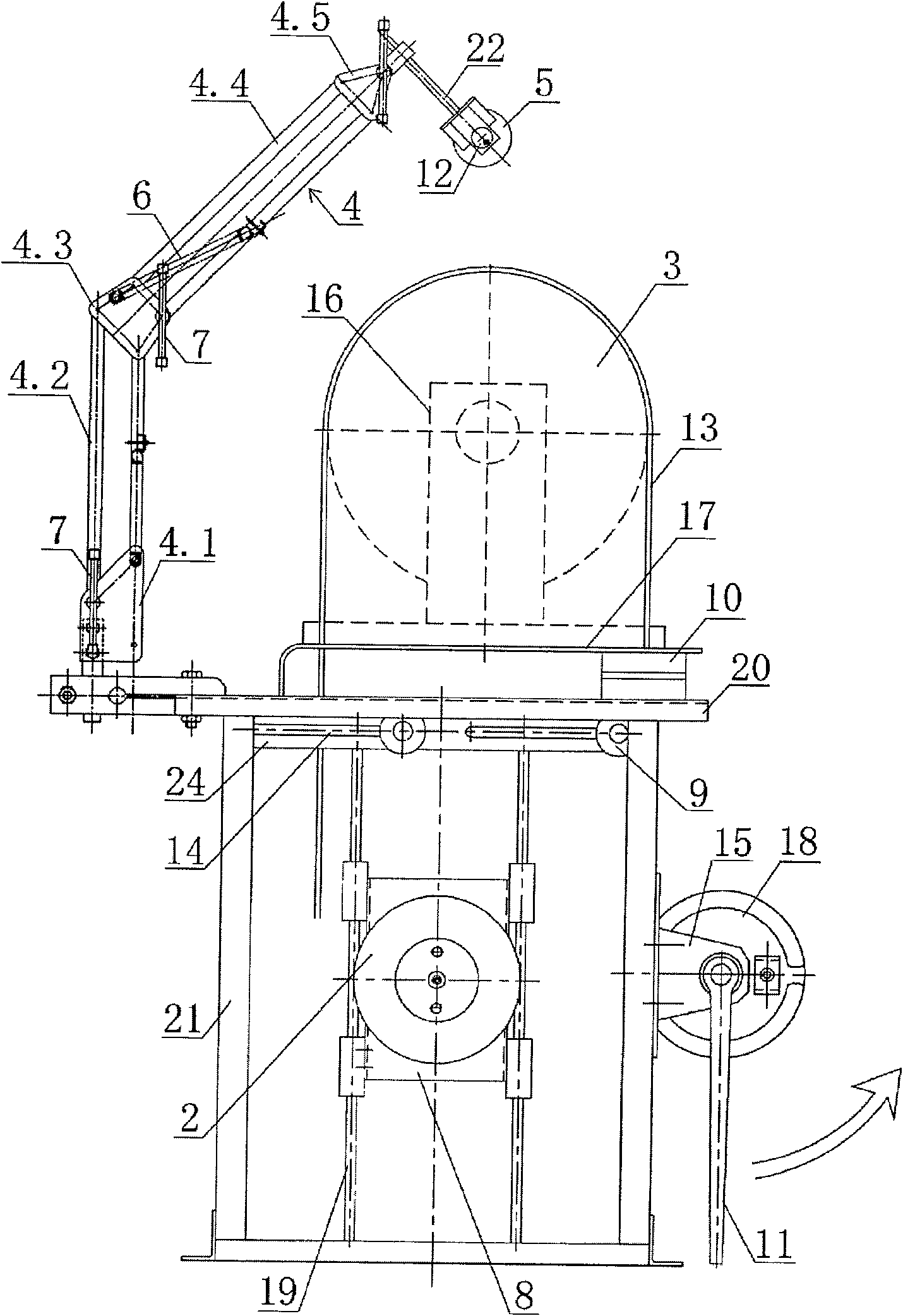

[0046] Examples see Figure 1-3 As shown, this two-in-one speed governor test bench includes a detection part and a control part, and the detection part includes a pedestal, which is characterized in that the pedestal is respectively connected with the speed measuring mechanism and the force measuring mechanism of the detection part.

[0047]Bench: including a table top 20 supported on a stand 21, the table top 20 has holes for passing steel wire ropes, and the stand 21 is frame-shaped.

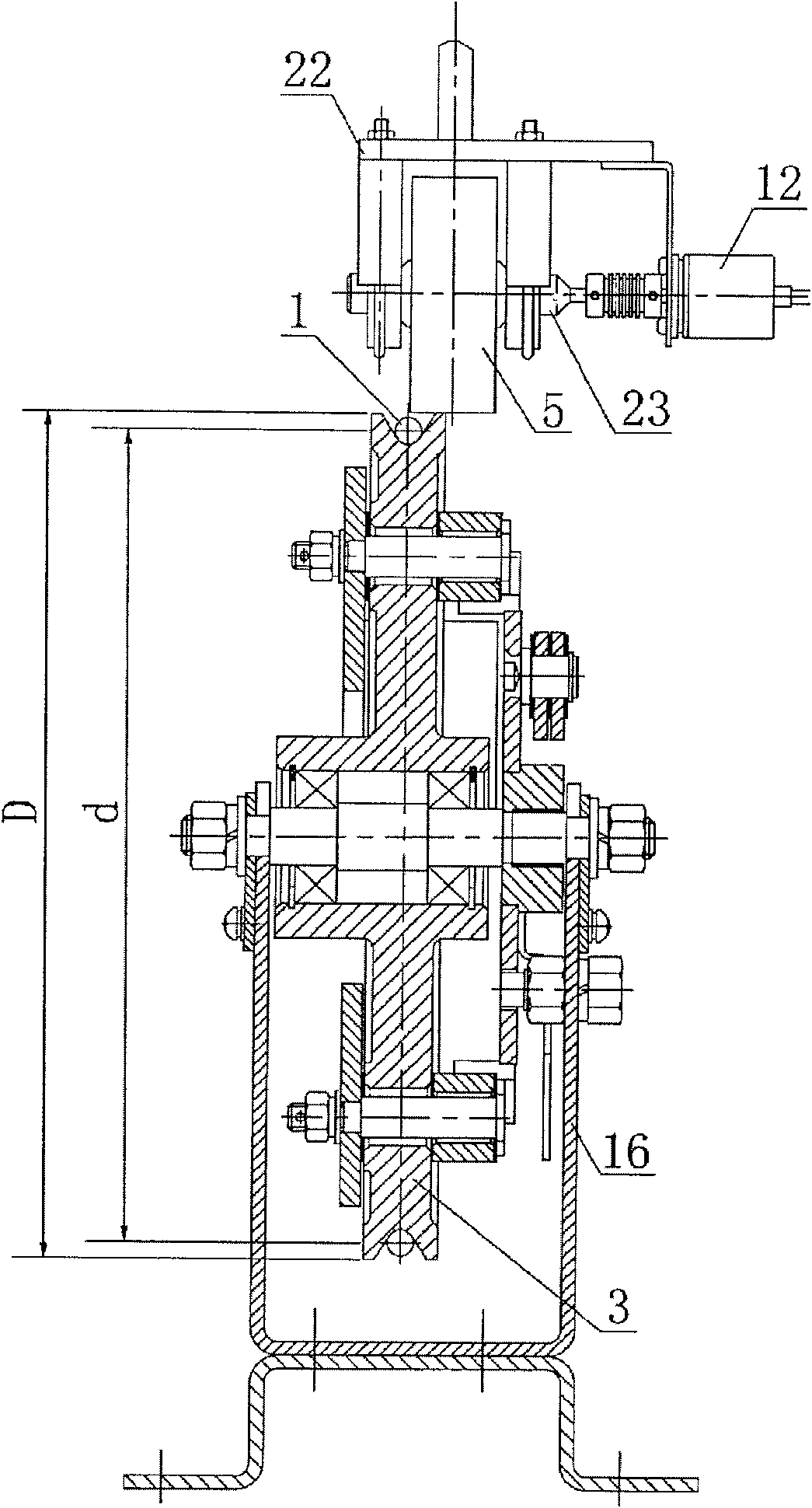

[0048] see Figure 1-2 , speed measuring mechanism: a speed limiter wheel frame 16 for connecting the speed limiter wheel 3 is fixed on the table top 20, and an O-shaped transmission belt 1 is wound in the wheel groove of the speed limiter wheel 3; the horizontal fixed adjustment plate 24 below the table top 20 On the adjustment plate, there is an adjustment horizontal hole 14 relative to the steel wire rope above, and two tensioning and adjustment wheels 9 pass through the adjustment horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com