Rechargeable lithium battery electric soldering iron device with temperature regulation, temperature control and constant temperature functions

A technology of lithium batteries and electric soldering irons, which is applied in the direction of soldering irons, manufacturing tools, welding equipment, etc., can solve the problems of short use time and slow temperature recovery, improve the use effect, realize constant temperature welding, and prolong the use time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

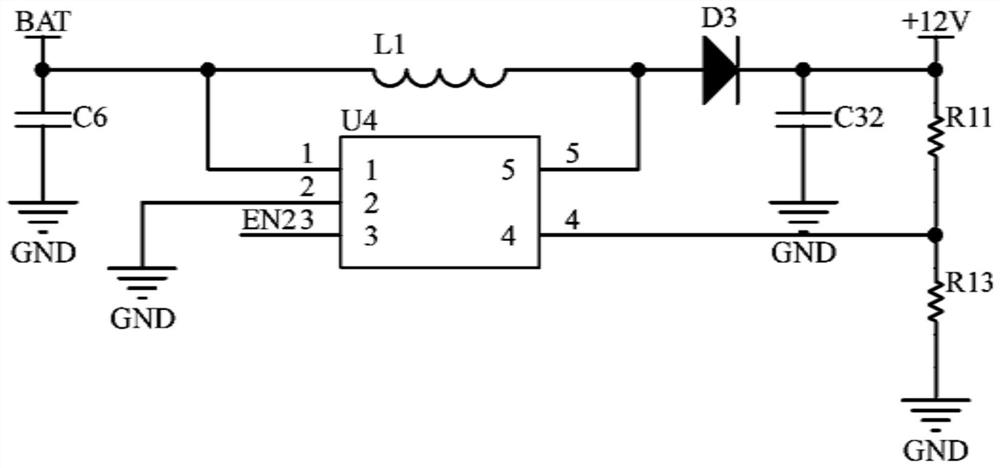

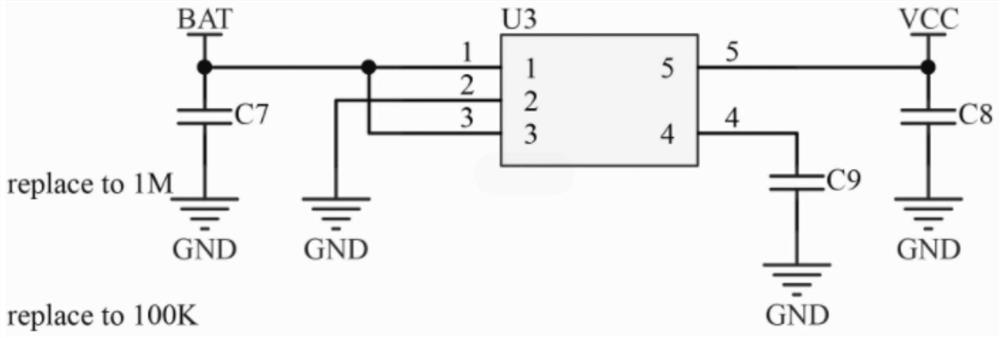

[0043] In the application of this embodiment, while the attached circuit is working, the auxiliary circuit can be loaded for support. For the power supply module, boost module, single-chip microcomputer or screen driver, etc., it can be operated according to the usual electrician operation process in the industry under the permission of the original circuit design Debug the designed application circuit, such as the stable output of current and voltage signals, the plug-in circuit of the chip, etc., can be used for debugging. Among them, the electrical components in the attached drawings can be used directly in comparison with the circuit connections in the drawings, and can be realized by using conventional technology in the industry, without limitation.

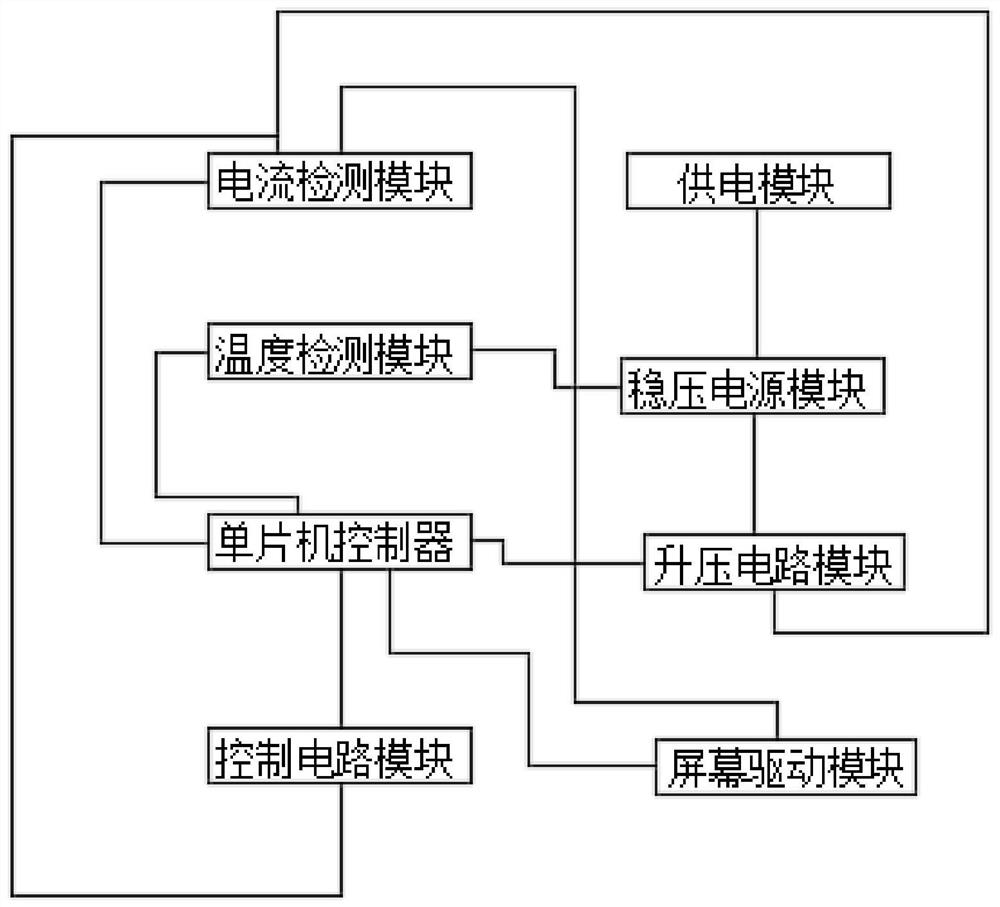

[0044] as attached figure 1 as shown,

[0045]A rechargeable lithium battery electric soldering iron device with temperature regulation, temperature control and constant temperature, comprising:

[0046] Power supply modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com