Butt-joint ring welding device used for new energy natural gas pipeline mounting

A natural gas pipeline and docking ring technology, which is applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as easy leakage, welding wire winding, and difficult control of welding seam depth, so as to ensure sealing and uniformity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

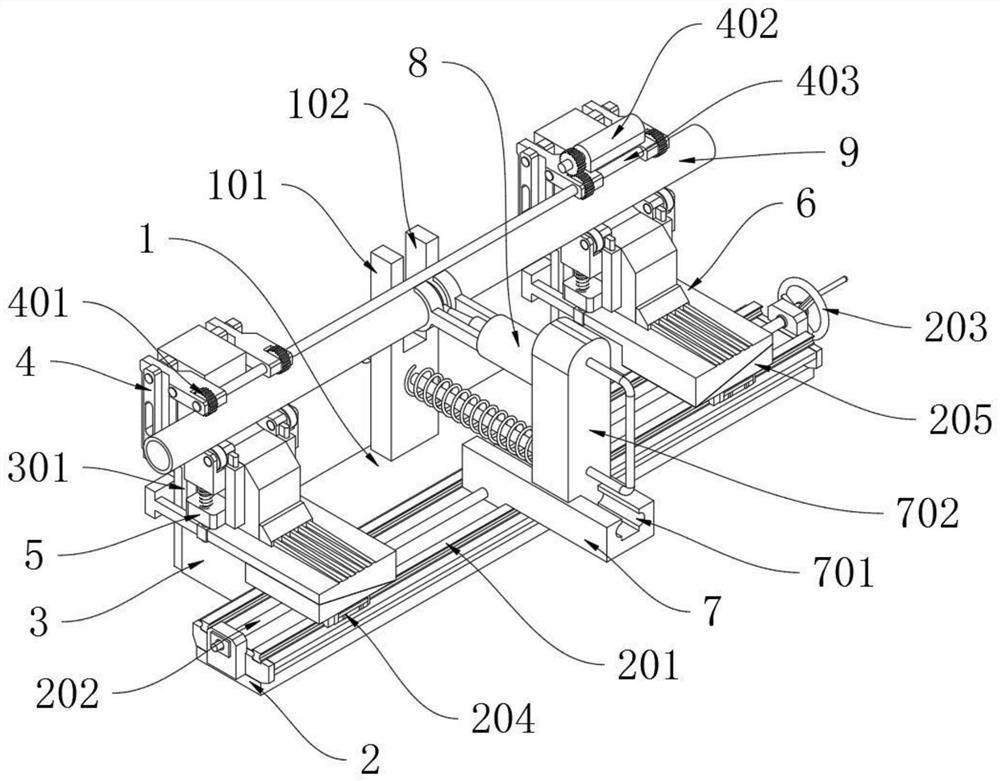

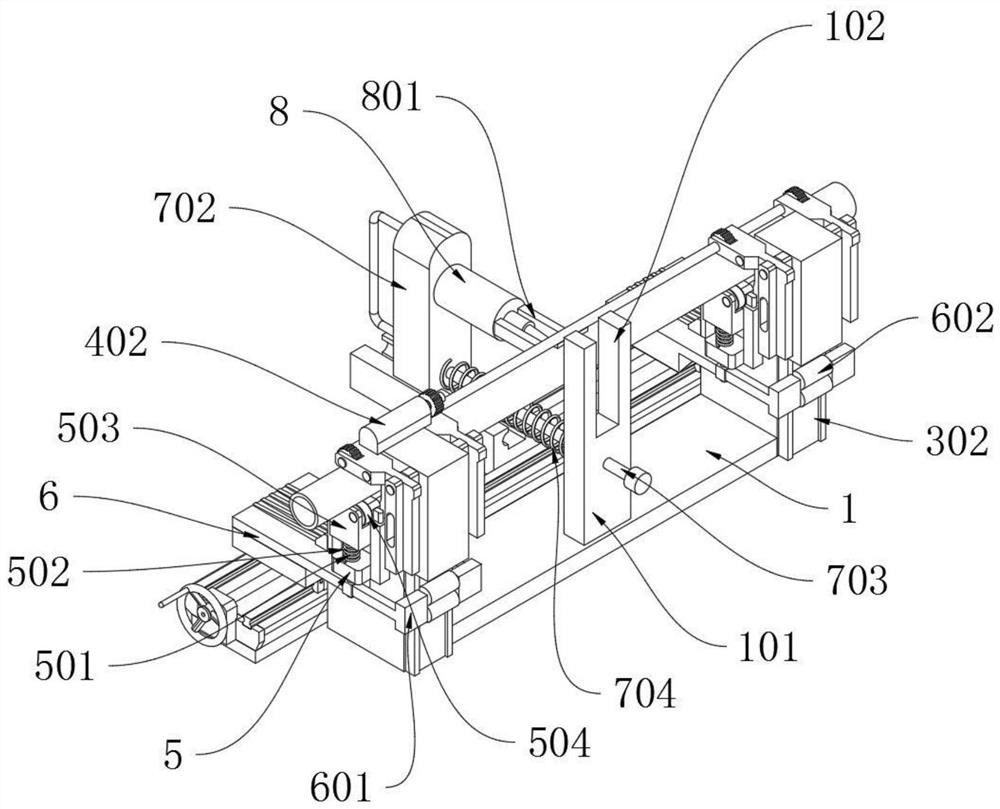

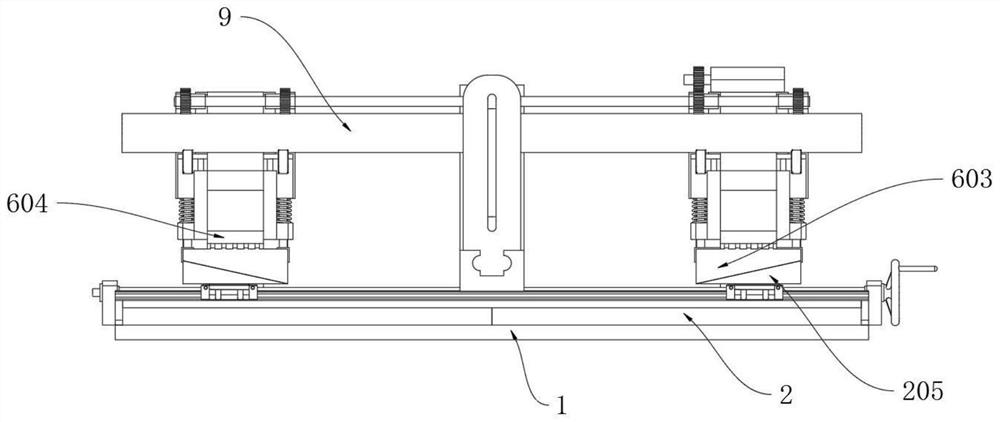

[0035] as attached figure 1 to the attached Figure 8 shown:

[0036] The present invention provides a butt girth welding device for installation of new energy natural gas pipelines, comprising a base 1; a lift table 2 is fixedly butt-jointed at the front end of the base 1; , sliding seat 204 and extrusion block 205, slide rails 201 are installed laterally at the front edge and rear edge of the top plane of the lift table 2 respectively, and the lift table 2 between the slide rails 201 is rotated and installed with double The head screw 202 has reverse threads at both ends of the double-head screw 202, a hand wheel 203 is fixedly installed on the right end of the double-head screw 202, and two sliding seats 204 are installed symmetrically between the two sliding rails 201. The bottom of the sliding seat 204 is screwed with one end of the corresponding double-ended screw rod 202. Wedge-shaped extrusion blocks 205 are fixedly installed on the top planes of the two sliding seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com